Method for increasing yield of prodn. of hypericum japonicum total flavone

A technology of Tianjihuang and total flavonoids, applied in the pharmaceutical field, can solve the problems of destroying the structure of flavonoids, loss of biological activity, decline in adsorption performance of macroporous resin, etc., and achieve the effect of improving solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

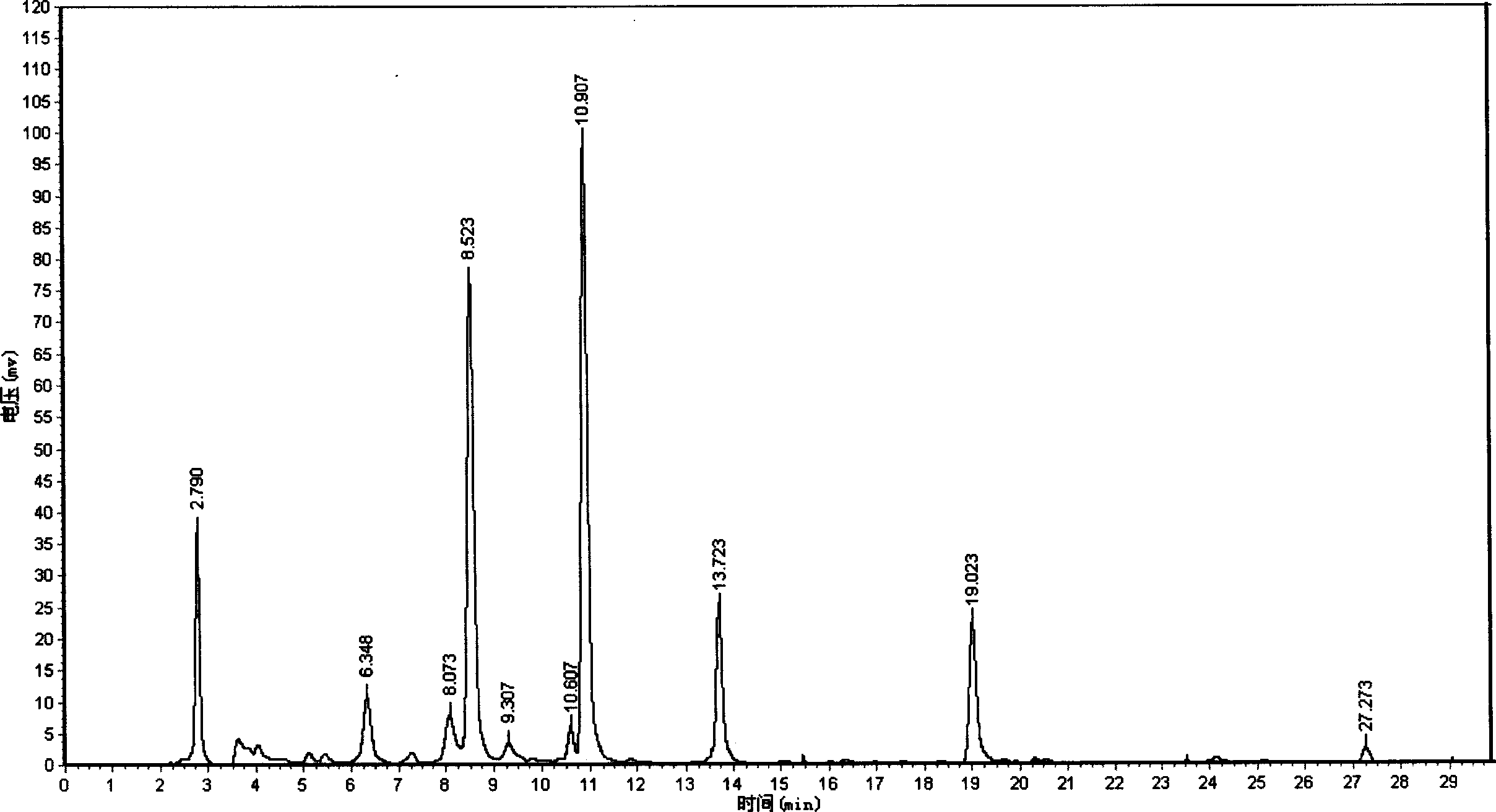

Embodiment 1

[0013] Take 2 kg of Tianjihuang medicinal material coarse powder, add 6 times of water, heat and reflux for extraction once, each extraction time is 0.5 hours, combine the extracts, and centrifuge (rotating speed 2000, time 5 minutes); Concentrate the water extract to relative density 1.2, add 0.25% NH 3 .H 2 O is dissolved and diluted to make the concentration to 0.25g crude drug / mL, pH to 4, centrifuge again, the supernatant is passed through a chromatographic column equipped with D101 type macroporous adsorption resin (non-polar), and the extract is prepared according to Tianjihuang The ratio of the amount of crude drug to the dry resin is 1:1, the column flow rate is 1BV / h, and the diameter-to-height ratio of the resin is 1:3; the resin is washed with water for 3BV, the elution flow rate is 1BV / h, and the water eluent is discarded; 2BV was eluted with 30% aqueous ethanol at a flow rate of 1BV / h, and the ethanol eluate was collected; the ethanol eluate was concentrated und...

Embodiment 2

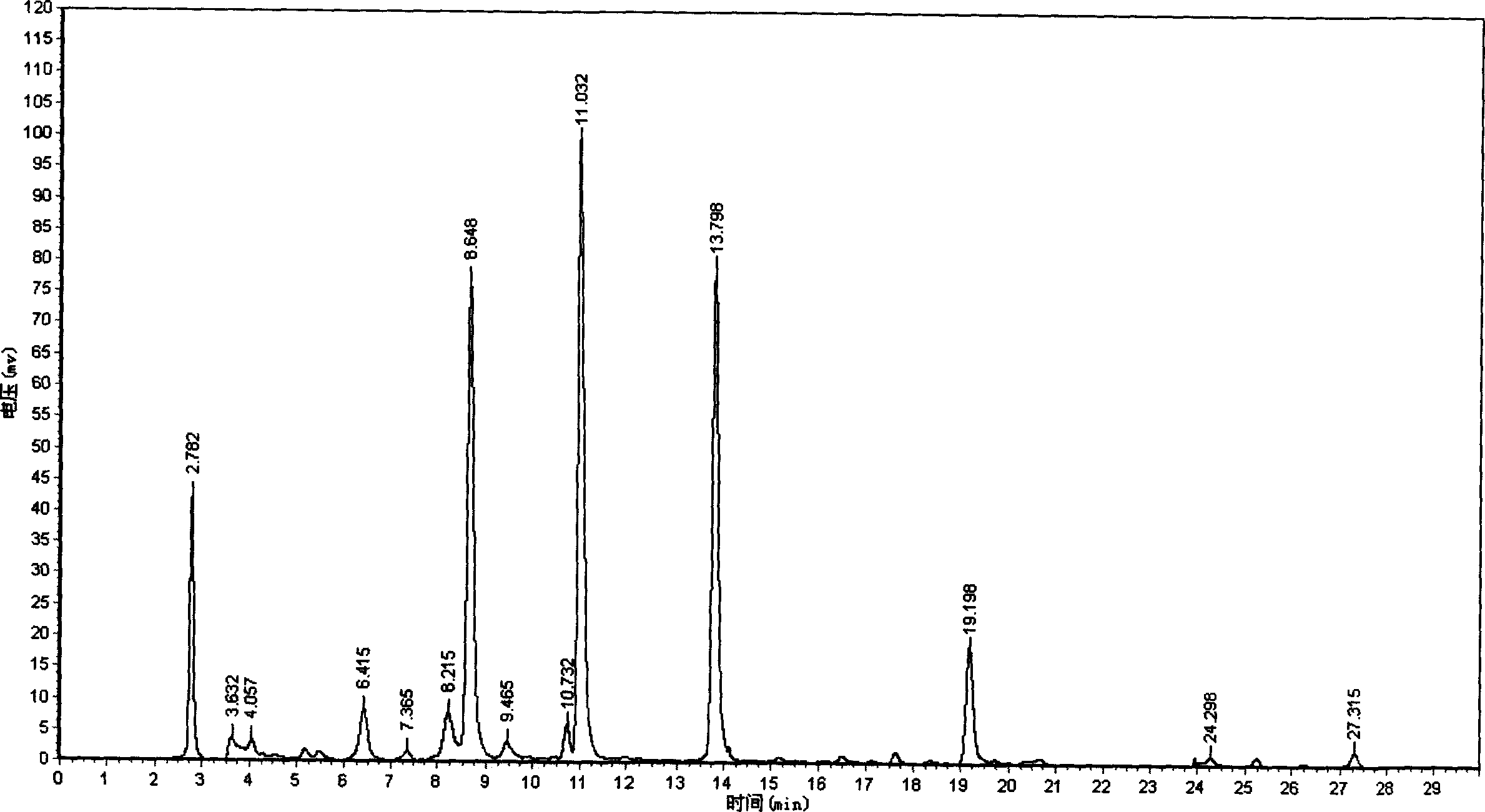

[0015] Take 2 kg of decoction pieces of Tianjihuang medicinal material, add 12 times of 95% ethanol, heat and reflux extraction 3 times, each extraction time is 3.0 hours, combine the extracts, and centrifuge (rotating speed 10000 rpm, time 90 minutes); the ethanol extract Concentrate to a relative density of 1.35, add 1.0% NH 3 .H 2 O is dissolved and diluted to make its concentration to 1.0g crude drug / mL, pH to 8, and centrifuged again. The supernatant is passed through a chromatographic column equipped with AB-8 type macroporous adsorption resin (weak polarity), and the extract is obtained by field The ratio of base yellow crude drug to dry resin is 1:5, the column flow rate is 4BV / h, and the diameter-to-height ratio of the resin is 1:9; the resin is washed with water for 12BV, and the elution flow rate is 6BV / h, and the water is discarded for elution. solution; elute with 6BV of 95% ethanol with water, the flow rate is 6BV / h, collect the ethanol eluate; concentrate the e...

Embodiment 3

[0017] Take 1 kg of decoction pieces of Tianjihuang medicinal material, add 8 times 50% ethanol, heat and reflux extraction twice, each extraction time is 2.0 hours, combine the extracts, filter; concentrate the ethanol extract to a relative density of 1.2, add 0.5% NH 3 .H 2 O is dissolved and diluted to make the concentration to 0.5g crude drug / mL, pH to 6, centrifuge again, the supernatant is passed through a chromatographic column equipped with AB-8 type macroporous adsorption resin (weak polarity), and the extract is obtained by field The ratio of base yellow crude drug to dry resin is 1:3, the column flow rate is 2BV / h, and the diameter-to-height ratio of the resin is 1:5; the resin is washed with 6BV of water, the elution flow rate is 3BV / h, and the water is discarded. Eluate: elute with 4-6BV of 70% ethanol with water, the flow rate is 2BV / h, collect the ethanol eluate; concentrate the ethanol eluate under reduced pressure to a relative density of 1.1, and dry to obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com