Preparation method of cassava hydroxypropyl distarch glyceride

A technology for tapioca hydroxypropyl distarch glycerol and tapioca starch, which is applied in the field of preparation of tapioca hydroxypropyl distarch glycerol ether, can solve the problems of unevenness, poor product quality, small seeds in planting area, etc., and achieves low production cost , high-quality, high-transparency effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

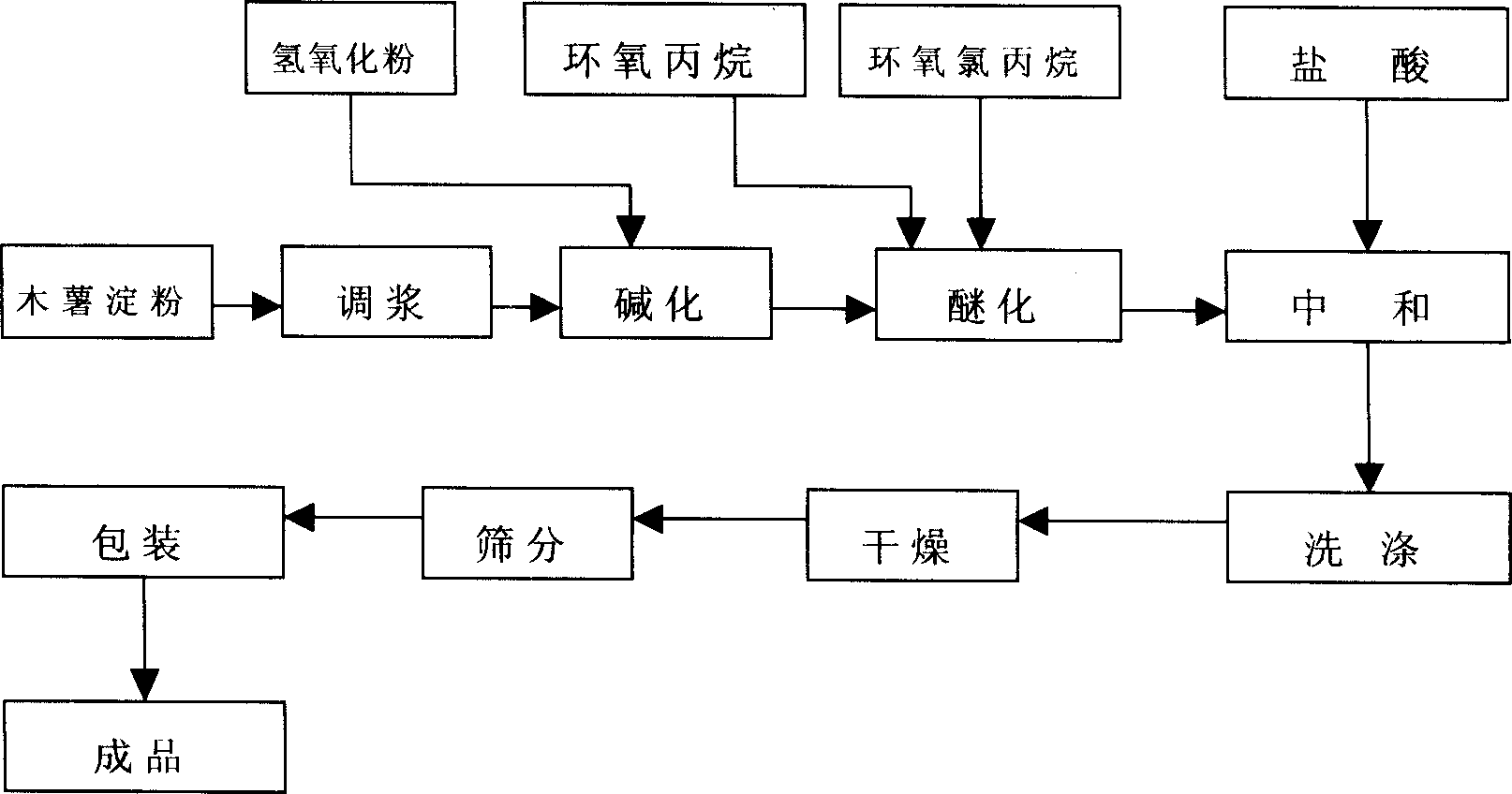

Image

Examples

Embodiment 1

[0022] Embodiment 1: first 100 kilograms of tapioca starch, 15 kilograms of sodium sulfate and 180 kilograms of water are adjusted into 20-23Be starch slurry in the reactor, constantly stirred, and adding mass concentration in the kettle is 3-4.0% sodium hydroxide solution to adjust PH value 11.0, alkalization for 40 minutes, add 4.5 kg of propylene oxide, keep the temperature at 42°C to react, add 5ml of epichlorohydrin for 10 hours of reaction, continue to react for 25 hours, add hydrochloric acid solution with a mass concentration of 8-10% Neutralize to a pH value of 6.0-7.0, add 200 kg of water to the kettle to wash, settle, and then wash in the same way to remove impurities (sodium sulfate, sodium chloride or other chemical residues) to obtain a finished product.

Embodiment 2

[0023] Embodiment 2: The steps are the same as in Embodiment 1, except that the amount of propylene oxide added in the etherification process is 4.0 kg, and the reaction temperature is maintained at 40°C.

Embodiment 3

[0024] Embodiment 3: The steps are the same as in Embodiment 1, except that the amount of propylene oxide added in the etherification process is 4.0 kg, and the reaction temperature is maintained at 45°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com