System and method for testing device unit of phase change storage

A technology of phase change memory and test system, applied in the field of micro-nano electronics, can solve the problem of no standard test system and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

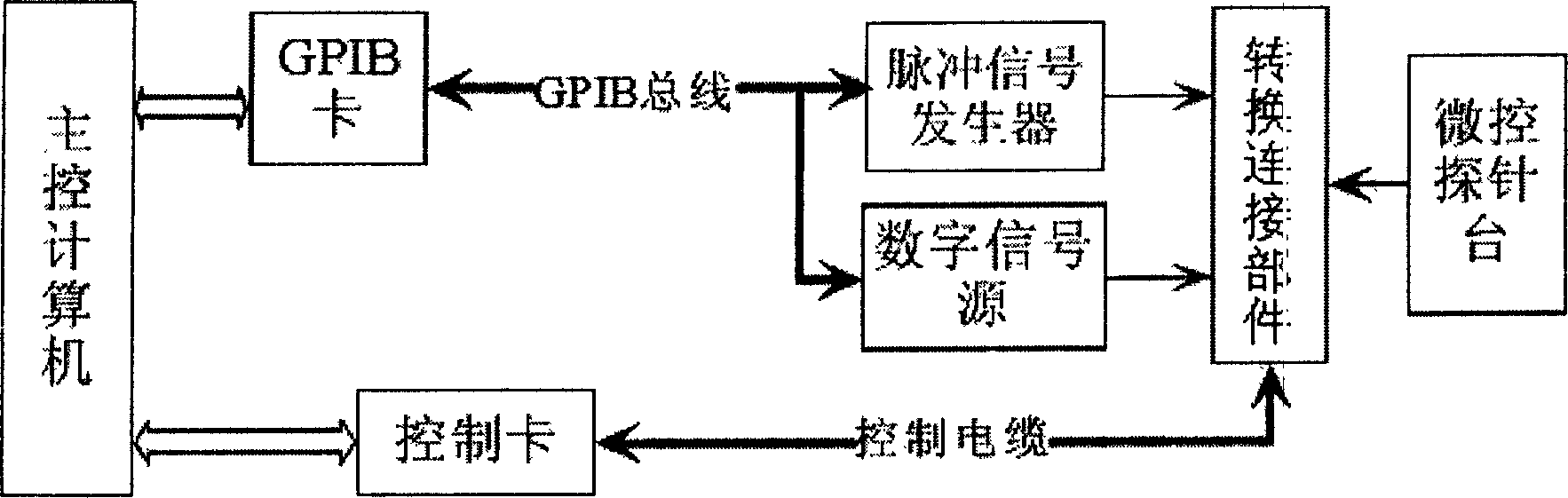

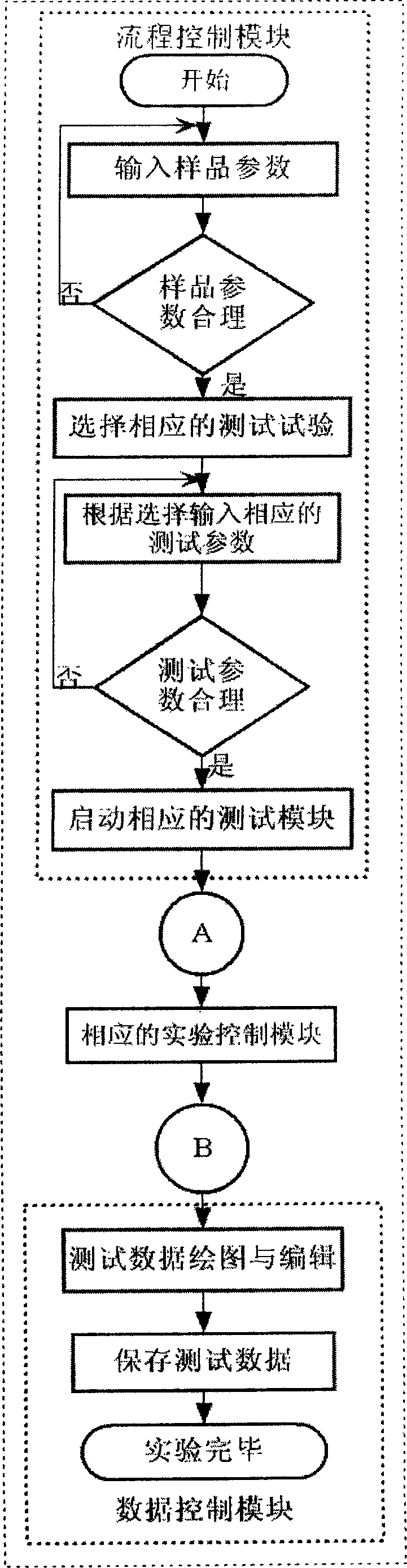

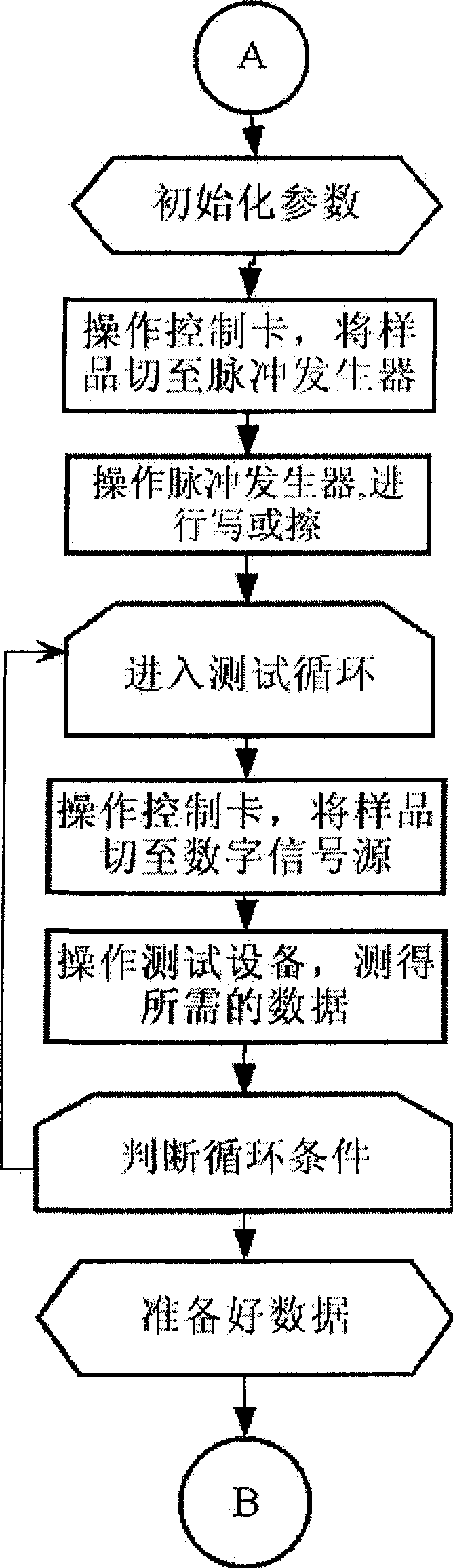

[0035] Image 6 It is a physical diagram of a phase change memory device unit test system. It is composed of control computer, control software, pulse signal generator, digital signal source, micro-control probe station and conversion connection parts and other hardware. Its operating software mainly includes current - Voltage test module, voltage-current test module, resistance and write pulse height test module, resistance and write pulse width test module, resistance and wipe pulse height test module, resistance and wipe pulse width test module, fatigue test module and other seven tests module. Among them, the model of the pulse signal generator is 81104A, and the manufacturer is Agilent Corporation of the United States. The pulse signal generator can generate pulse signals in single-channel and dual-channel modes. The pulse signal is characterized by: it can be a single pulse or a continuous pulse signal ;The shape characteristic of the pulse signal is a single shape or a...

Embodiment 2

[0038] Change the current-voltage test module used in embodiment 1 into a voltage-current test module, and the specific test parameters are as follows: the current test range is 0-1.75mA, and the step of current increase is 0.05mA, and all the other are the same as in embodiment 1. Record the corresponding current and voltage values to get the voltage-current curve (such as Figure 9 shown). Depend on Figure 9 It is known that the critical phase change current and the critical phase change voltage for crystallization of the phase change material in the device unit are 0.1mA and 0.46V.

Embodiment 3

[0040] Change the current-voltage test module used in embodiment 1 into a resistance and write pulse high test module, and the specific test parameters are as follows: the current test range is 0.001-4.001mA, the step of the current increase is 0.1mA, and the width of the pulse current is 30ns, all the other are identical with embodiment 1, record corresponding electric current and resistance value and can obtain resistance-current curve (as Figure 10 shown). Depend on Figure 10 It is known that when the pulse current is lower than 3.0mA, the resistance is about 1000Ω, and the phase change film is still polycrystalline. Because the current is too low, the Joule heat provided is not enough to melt the film, so the amorphous state cannot be obtained. However, as the pulse current increases, the more Joule heat provided to the device unit, the greater the proportion of phase change material melting, so the proportion of the obtained amorphous state is also greater, and the res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com