Distribution methods for distributing and dispensing beverages and liquid food products

A liquid food and beverage technology, applied in liquid distribution, liquid flow control devices, liquid materials, etc., to achieve good sealing quality, cheap structure, and cost-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

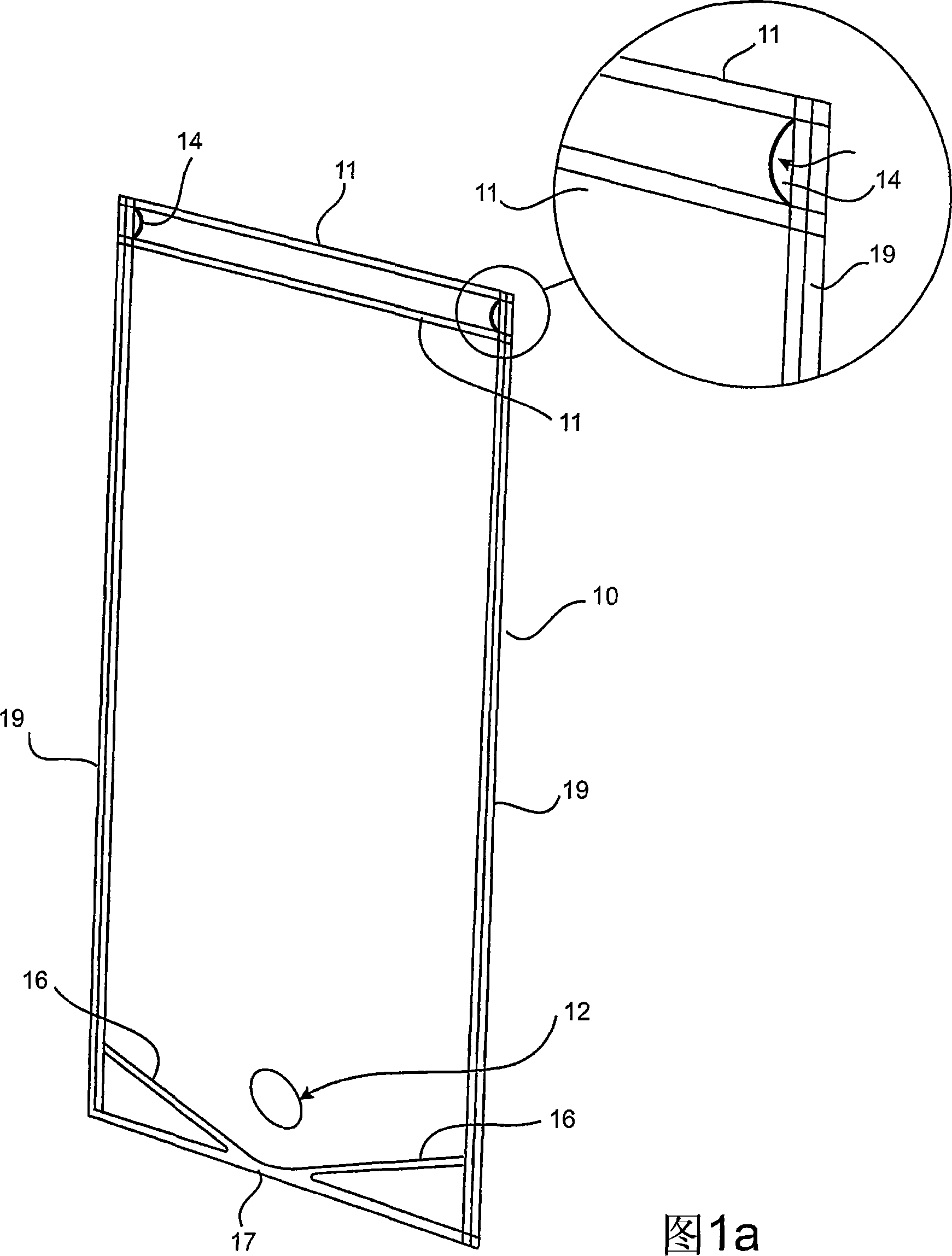

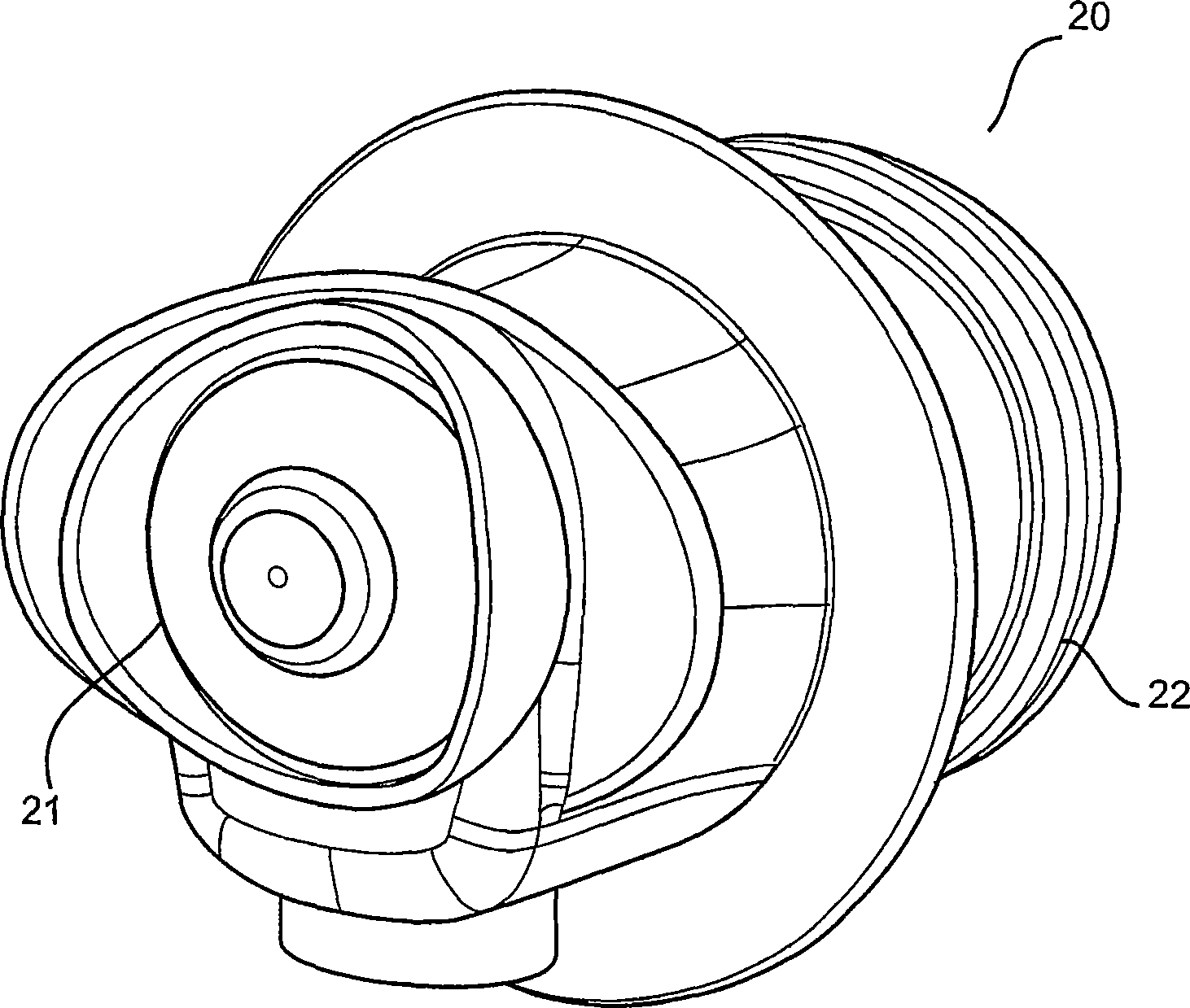

[0042] According to the dispensing method of the present invention, a distributor of beverages or liquid food uses a flexible bag 10 of the form shown in Figure 1a. This bag 10 is composed of polymeric construction for food grade applications and is designed to withstand typical handling, which may include wear and tear. Such a flexible bag 10 is fitted or formed with a valve, nozzle or cock at the tap hole 12 through which a beverage such as drinking water is guided to fill the bag. A suitable stopcock 20 is described in US 6,296,157 and US 6,360,925, filed in the name of Scholle Corporation, the contents of which are incorporated herein by reference. Such a cock 20 in Figure 1b Shown stereoscopically. It has an actuator 21 to start the flow of fluid and a ribbed end 22 for fitting the socket to the tap hole 12, the ribs forming a seal with the smooth interior of the tap hole 12. The absence of threads at the end 22 avoids potential abrasion and the risk of debris flowing ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap