Method of separating plastid DNA employing silicon oxide-magnetite nano composite

A nanocomposite, magnetite technology, applied in the field of separating plastid DNA

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Material:

[0045] Ferric chloride hexahydrate was purchased from J.T. Baker (Phillipsburg, NJ, USA). Ferrous chloride tetrahydrate was purchased from Fluka (Buchs, Switzerland). PEI, tetraethoxysilane, and lauric acid were all supplied by Sigma Chemical Co. (St. Louis, MO, USA). Sepharose L (low osmolarity) was obtained from Amersham Biosciences (Uppsala, Sweden). The supercoiled DNA ladder was obtained from Invitrogen Co. (Carlsbad, CA, USA). The reagents used in DNA isolation and analysis are of molecular biology grade. RNase A was obtained from Sigma. All other chemicals and solvents used were of analytical grade and used without further purification. The water used in the whole experiment was produced by Milli-Q Ultra-Pure-Water Purification System of Nihon Millipore Ltd. (Tokyo, Japan). All solutions were freshly prepared.

[0046] method:

[0047] 1. Plastid composition

[0048] The complete enhanced green fluorescent protein gene (EGFP) was amplified fr...

Embodiment 2

[0073] 1. Identification of magnetic particles

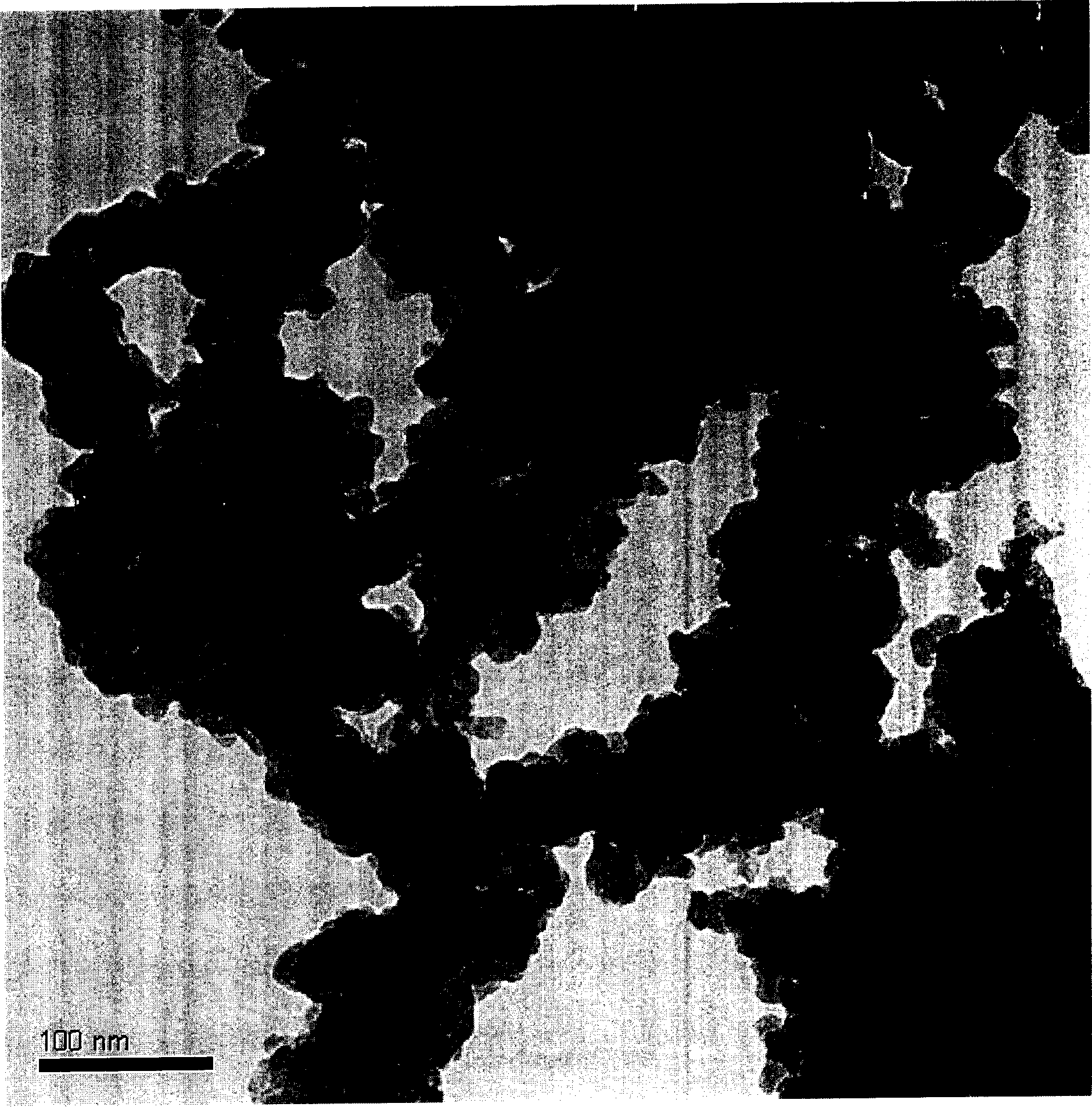

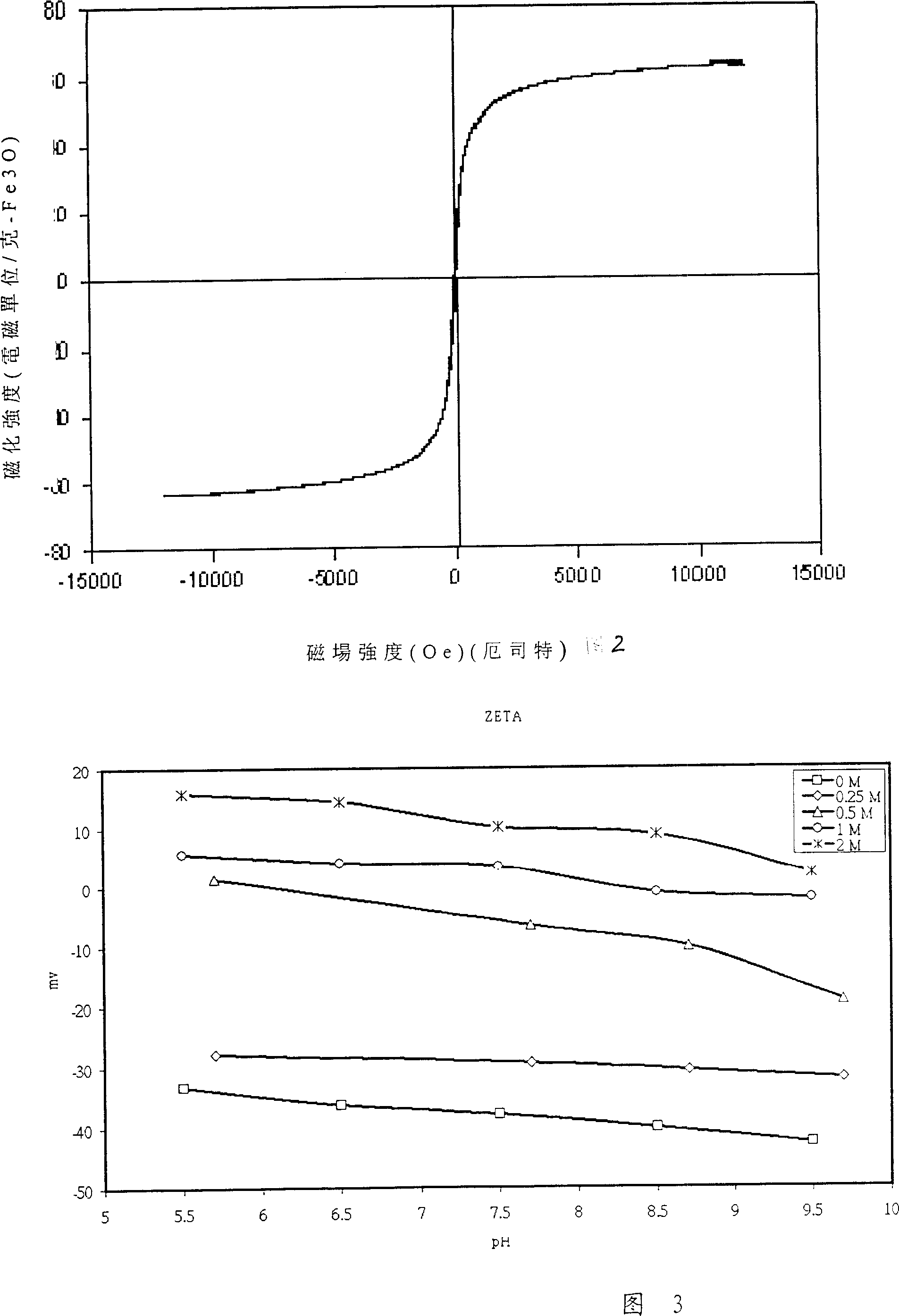

[0074] The size and morphology of the magnetic nanoparticles were identified by TEM. figure 1 Typical TEM micrograph showing magnetic particles. The superparamagnetic properties of the magnetic particles are confirmed by the magnetization curve measured by SQUID. Figure 2 shows a typical plot (M-H loop) of magnetization versus applied magnetic field at 298K. The resulting Fe 3 o 4 The saturation magnetization of the magnetic particles is 64emu / g Fe 3 o 4 . The large saturation magnetization of these magnetic particles makes them very sensitive to magnetic fields, thus allowing easy separation of solid and liquid phases. Very weak hysteresis reveals that the resulting magnetic nanoparticles are nearly superparamagnetic.

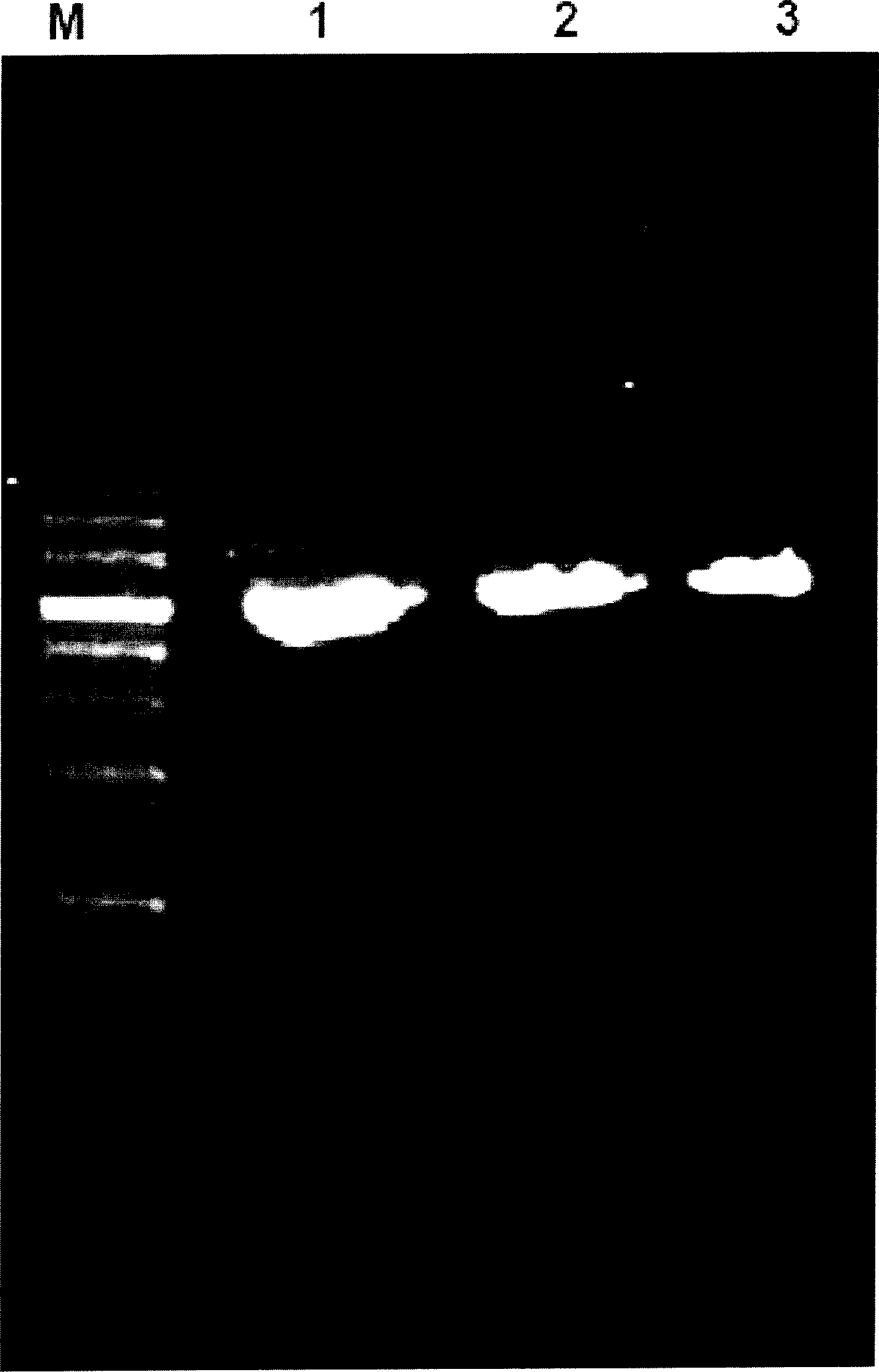

[0075] 2. The influence of ionic strength

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com