Hollow polymer fiber reinforced polymer modified emulsified thin asphalt slurry seal for abnormal cross-section

A special-shaped cross-section, emulsified asphalt technology, which is applied to the coagulation pavement, roads, roads and other directions paved on site, can solve problems such as poor resistance to permanent deformation, that is, poor durability, inability to adapt to large deformation of asphalt pavement, and inability to meet large traffic, etc. It can prevent the occurrence and development of cracks, improve the affinity and uniform mixing, and the implementation method is simple and easy to implement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Polymer modified emulsified asphalt: SBS polymer modified emulsified asphalt, the asphalt ratio is 6%.

[0024] Fiber: No fiber added.

[0025] Filler: 425# ordinary Portland cement is used, and the dosage is 2%. All performances meet the requirements of "Technical Specifications for Highway Asphalt Pavement Construction" (JTGF40-2004).

[0026] Main aggregate: sand and stone chips. All properties meet the requirements of "Technical Specifications for Construction of Highway Asphalt Pavement" (JTG F40-2004).

[0027] Sieve hole

Embodiment 2

[0029] Polymer modified emulsified asphalt: SBS polymer modified emulsified asphalt, the asphalt ratio is 6%.

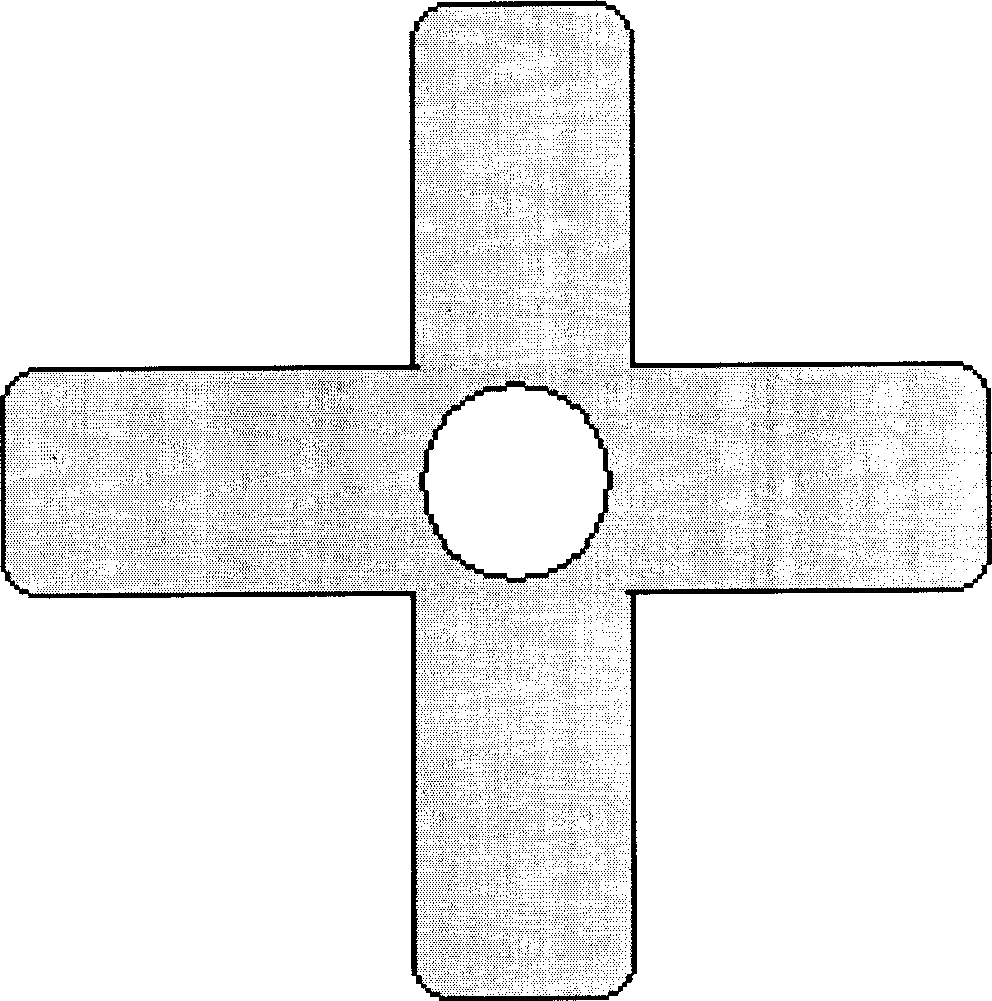

[0030] Fiber: for figure 1 The shown cross-section single-hole polyester fibers are all added in an amount of 0.10% of the total mass of the mixture.

[0031] Filler: 425# ordinary Portland cement is used, and the dosage is 2%. All performances meet the requirements of "Technical Specifications for Highway Asphalt Pavement Construction" (JTGF40-2004).

[0032] Main aggregate: sand and stone chips. All properties meet the requirements of "Technical Specifications for Construction of Highway Asphalt Pavement" (JTG F40-2004).

[0033] The mineral material gradation is as follows:

[0034] Sieve hole

Embodiment 3

[0036] Polymer modified emulsified asphalt: SBS polymer modified emulsified asphalt, the asphalt ratio is 6%.

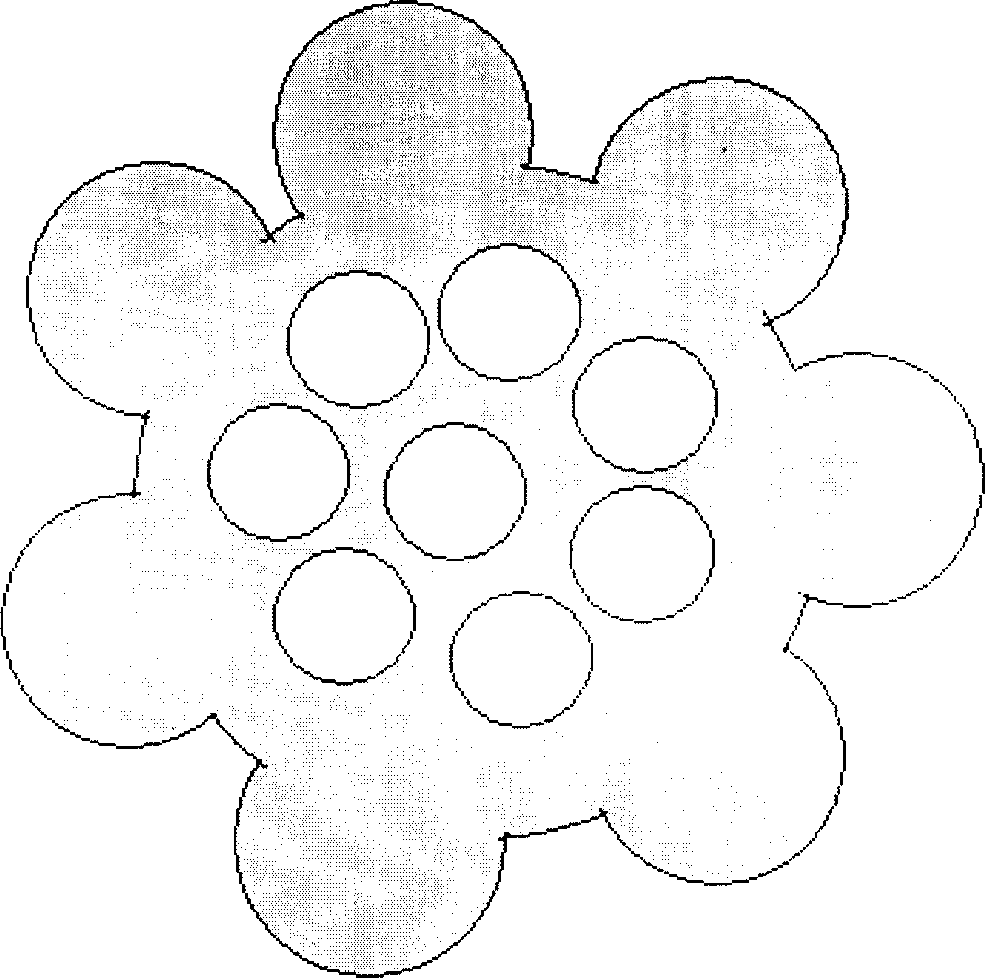

[0037] Fiber: for figure 2 The shown porous polyester fiber with quincunx cross-section is 0.15% of the total mass of the mixture.

[0038] Filler: 425# ordinary Portland cement is used, and the dosage is 2%. All performances meet the requirements of "Technical Specifications for Highway Asphalt Pavement Construction" (JTGF40-2004).

[0039] Main aggregate: sand and stone chips. All properties meet the requirements of "Technical Specifications for Construction of Highway Asphalt Pavement" (JTG F40-2004).

[0040] Sieve hole

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com