Shaping method of small curvature radius bend pipe

A forming method and small curvature technology, applied in the field of elbow manufacturing process, can solve the problems of increasing engine air intake resistance, unable to achieve excessive arc bending, and large diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

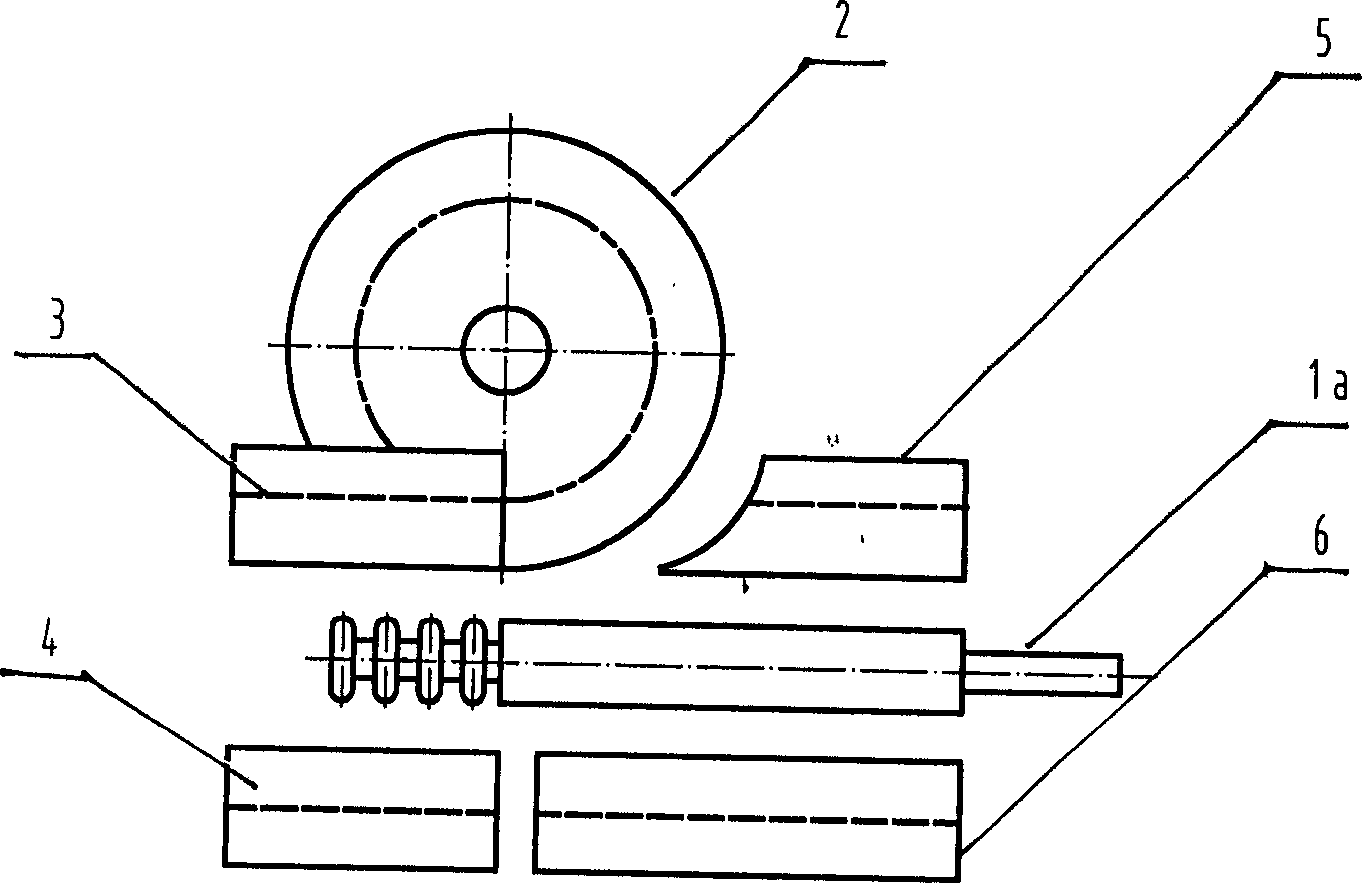

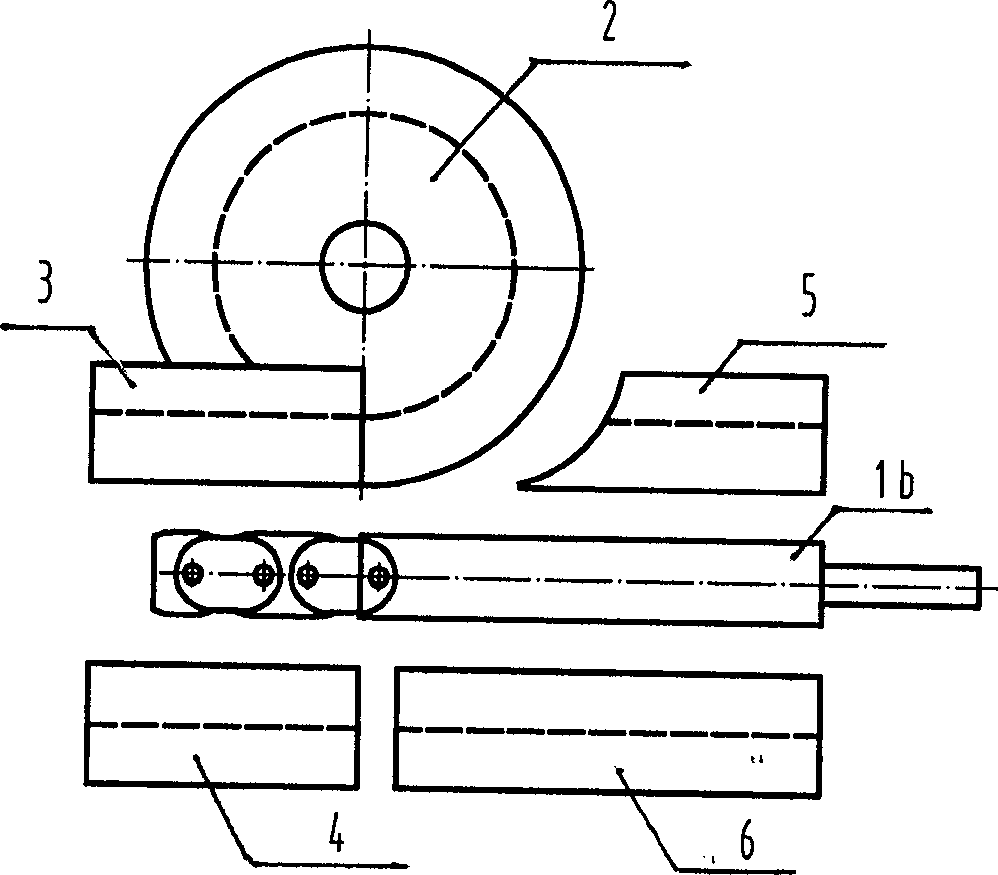

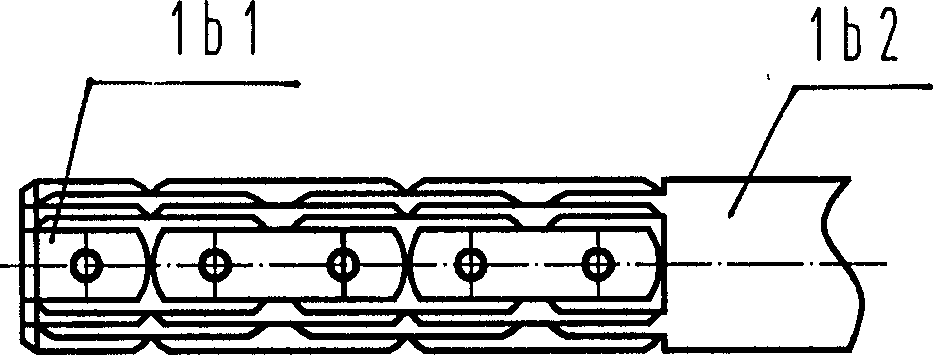

[0018] Such as figure 1 As shown, the mandrel of a set of mold used in this embodiment is a universal mandrel in the known technology. This universal mandrel is composed of 2 to 4 metal rings, and there is a certain gap between the rings. Utilize this mandrel according to the method of the present invention and can manufacture the metal elbow that pipe wall thickness is 2 millimeters, bending radius is 1.5D, and its specific method is: the original pipe blank to be bent is passed on the universal mandrel 1a, the original One end of the tube embryo 7 is fixed by the clamping force and the bending die, and the clamping force is provided by the cooperation of the clamping block 4 and the support block 3, and then the bending die 2 is driven by the numerical control pipe bending machine to rotate; in the process of bending and deforming the original tube blank, Such as Figure 9 As shown, two auxiliary thrusts in different directions are added to the tube wall of the original tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com