Catalyst for benzene ring hydrogenation of terephthalic acid or dimethyl terephthalate

A technology of dimethyl phthalate and terephthalic acid, which is applied in the field of catalysts for the hydrogenation of aromatic carboxylic acids or aromatic esters to achieve the effects of mild hydrogenation reaction conditions, good reactivity, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

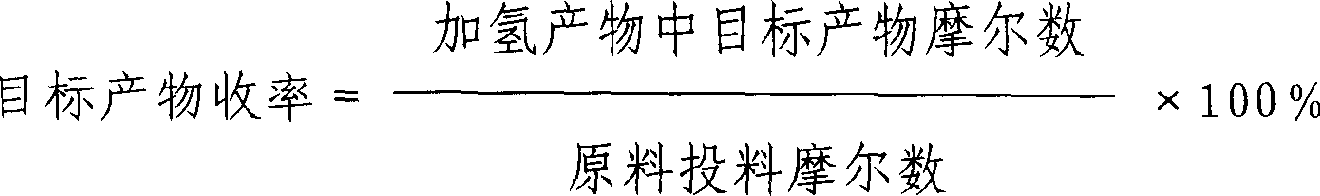

Method used

Image

Examples

Embodiment 1

[0016] 2gRuCl 3 ·xH 2 O (about 37% Ru) was dissolved in 325ml deionized water to make an impregnating solution, stirred and heated to 60°C, and 20% sodium hydroxide solution was added to adjust the pH value of the impregnating solution to 8. Add 14.3g carrier Al 2 o 3 Powder, continue stirring for 10 minutes. Cool to room temperature and stand for 0.5 hours, add 9.2g of 36% formaldehyde solution dropwise, stir for 1 hour, let stand for 0.5 hours, filter, and wash with deionized water 4 times to obtain the finished catalyst. The particle size of the catalyst is 80-200 head.

Embodiment 2

[0018] Change RuCl 3 ·xH 2 O and carrier Al 2 o 3 The consumption of adding 30% ammonium bicarbonate solution is adjusted to 5 by the dipping liquid pH value, and all the other are with embodiment 1.

Embodiment 3

[0020] Change RuCl 3 ·xH 2 O and carrier Al 2 o 3 The consumption of adding 20% sodium carbonate solution is adjusted to be 8 by the dipping liquid pH value, all the other are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com