Embedment structure of optical fiber and embedment method for enhancing cohesive force between optical fiber and packaging material

A technology of packaging material and packaging material layer, applied in the direction of optical fiber/cable installation, etc., can solve the problems of inability to guarantee the accuracy of measurement, affect the protection effect of optical fiber, and reduce the sensitivity of sensing elements, etc., and achieve excellent mechanical properties, good resistance Aging properties, effects that are easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Apply the modified acrylate adhesive evenly on the surface of the coating layer to be embedded in the optical fiber, and it will be completely solidified after one minute. increase the surface area of the fiber.

[0020] After the adhesive is completely solidified, soak the part of the optical fiber to be embedded in silane coupling agent A-151 (vinyltriethoxysilane), soak for 5 to 10 minutes, take it out and dry it; Add coupling agent A-151 (vinyltriethoxysilane) at a mass ratio of coupling agent = 100:1, stir evenly, add curing agent according to the mass ratio of silicone rubber: curing agent = 50:1, and stir evenly again; Next, the optical fiber is placed in a cylindrical mold with a diameter of 1 cm for positioning, and the part to be embedded is located on the central axis of the mold; finally, silicone rubber is filled, and the silicone rubber is solidified.

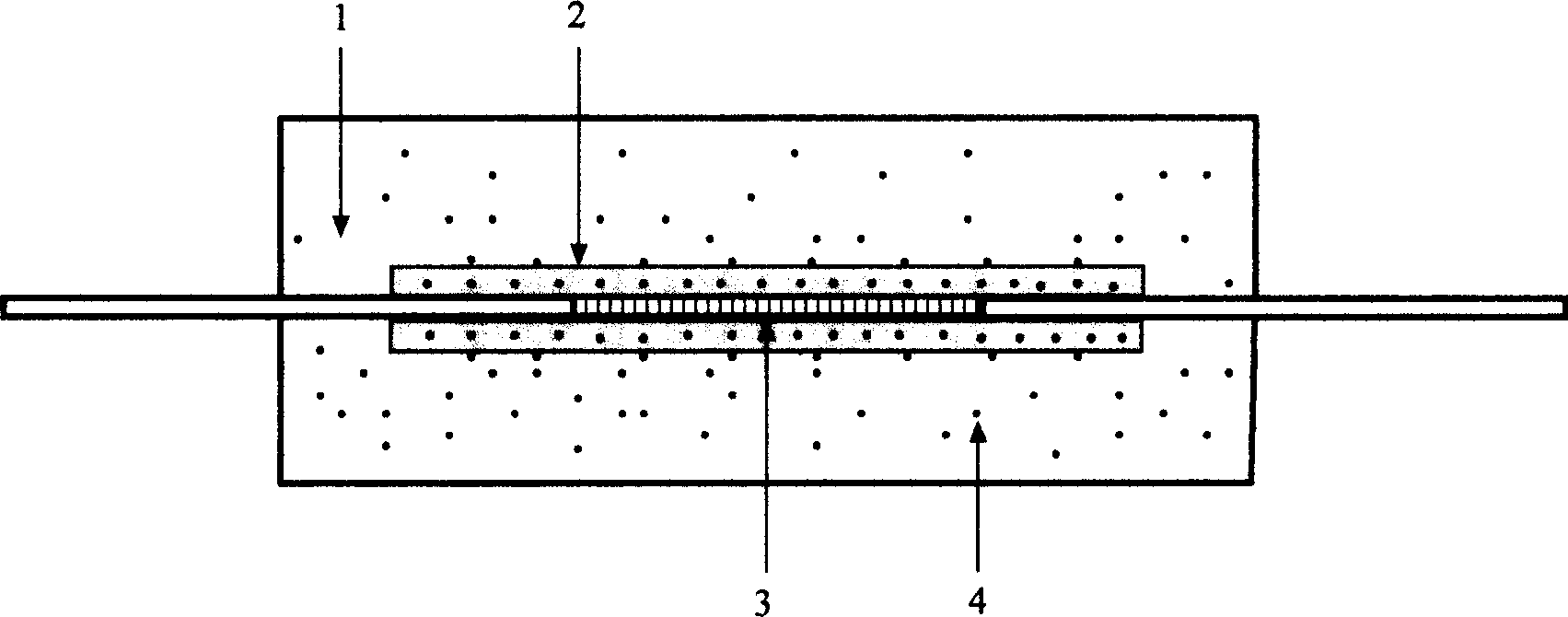

[0021] The resulting embedded structure is as figure 1 As shown, 1 is the silicone rubber layer (tha...

Embodiment 2

[0023] Evenly apply mixed universal glue (the main component is epoxy resin) on the surface of the coating layer of the optical fiber to be embedded, and it will be completely solidified after ten minutes. The silicone rubber bond increases the surface area of the fiber.

[0024] After the adhesive is completely solidified, soak the part of the optical fiber to be embedded in the silane coupling agent N-(β-aminoethyl-)-Y-aminopropyltriethoxysilane, take it out and dry it after soaking fully; In silicone rubber, add coupling agent N-(β-aminoethyl-)-Y-aminopropyltriethoxysilane according to the mass ratio of silicone rubber: coupling agent=100:2, and stir according to the silicone rubber: Curing agent = mass ratio of 100:1. Add the curing agent to the silicone rubber, and stir again; then place the optical fiber in a cylindrical mold for positioning, and the part to be embedded is located on the central axis of the mold; Filling of rubber, after the silicone rubber is solidif...

Embodiment 3

[0026] Evenly coat the surface of the coating layer of the optical fiber to be embedded with glass glue whose main component is acrylic ester, and it will be completely solidified after five minutes. Bonding increases the surface area of the fiber.

[0027]After the adhesive is completely solidified, soak the part of the optical fiber to be embedded in the silane coupling agent KH-550 (γ-aminopropyltriethoxysilane), take it out and dry it after soaking fully; press the silicone rubber in the silicone rubber Add the coupling agent KH-550 (γ-aminopropyltriethoxysilane) at the mass ratio of coupling agent = 100:5, and add the curing agent according to the mass ratio of silicone rubber: curing agent = 75:1 after stirring evenly , Stir evenly again; Next, place the optical fiber in a cylindrical mold for positioning, and the part to be embedded is located on the central axis of the mold; Finally, fill the silicone rubber, and wait for the silicone rubber to solidify.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com