New X ray tube, and fabricating method

An X-ray tube and X-ray technology, applied in the field of new X-ray tubes, can solve problems such as increasing system complexity, reducing X-ray flux utilization, and large distance from source to detector

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

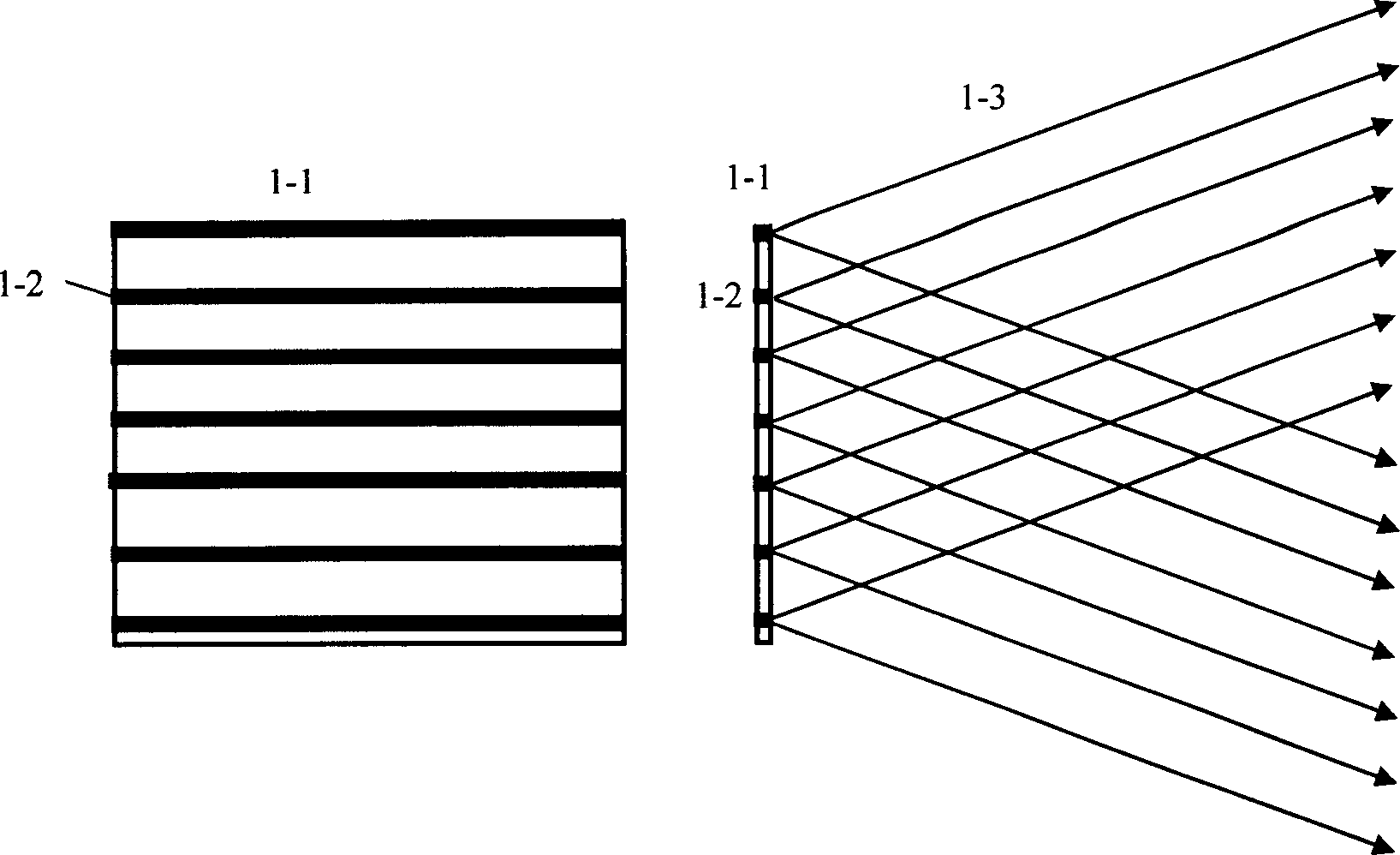

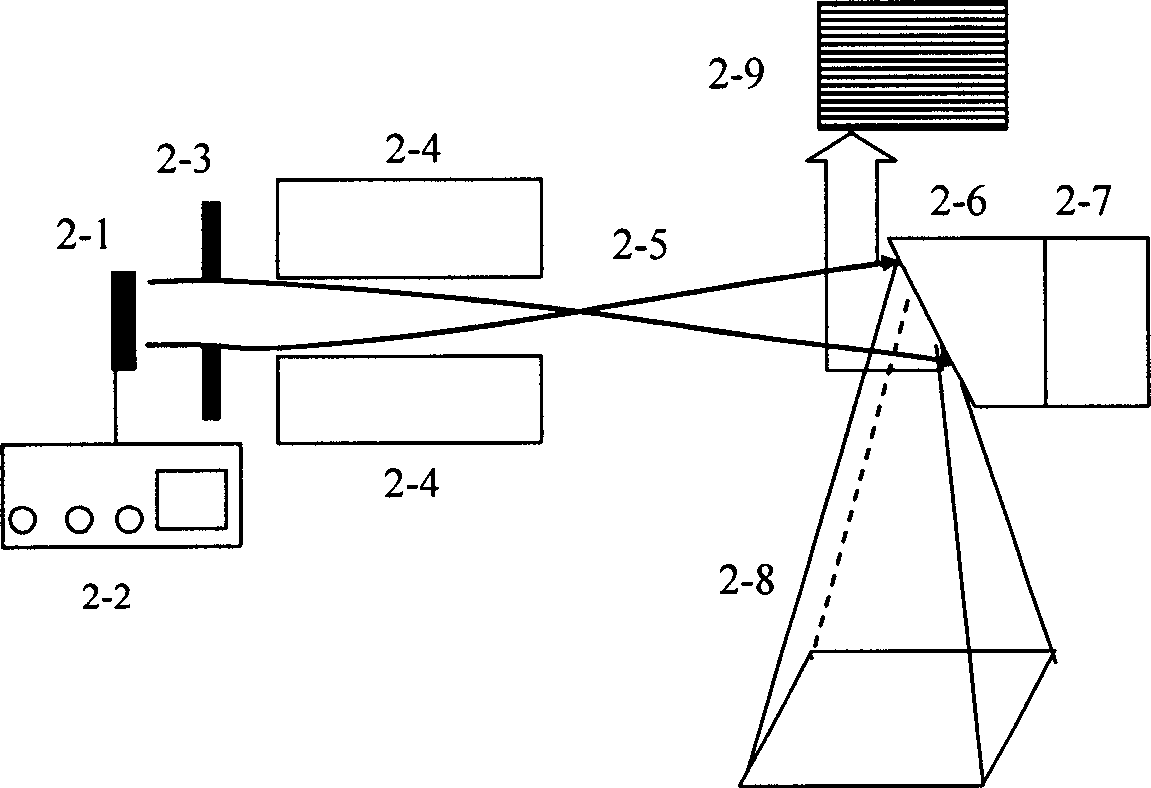

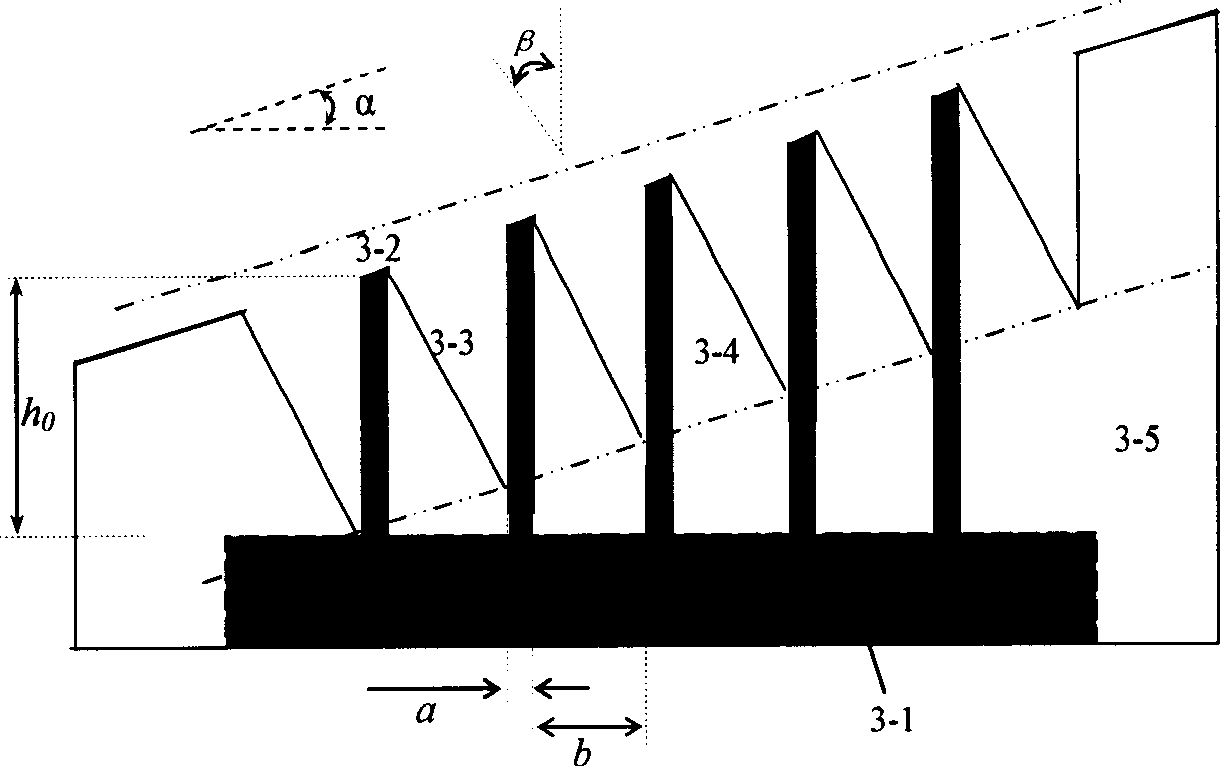

[0030] The second example of the present invention: electron beam scanning X-ray tube

[0031] An electron beam scanning X-ray tube consists of an electron emitter, a grid, a focusing electrode, a deflection yoke, and a conventional unstructured anode (Fig. 7). The electron emitter (7-1) produces a small spot electron beam (7-5) under the control of the power supply and control system (7-8), which is accelerated by the grid (7-2) and focused by the focusing electrode before entering the deflection yoke (7-3A, 7-3B are horizontal deflection and vertical deflection respectively). The deflection system enables the small beam spot electron beam to scan quickly in two dimensions on the anode (7-6). The distribution of the electron beam on the anode forms a parallel line structure whose line width is the diameter of the beam spot. The scanning range is the X-ray beam line The effective area of the emitter array. At any moment in the scanning process, only one point on the anode ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com