Method of continuous purifying hydrogen generated by electrolyzing water

A technology of purifying water and water electrolysis, applied in chemical instruments and methods, electrolysis process, electrolysis components, etc., can solve the problems of air pollution, waste of hydrogen energy, etc., and achieve significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

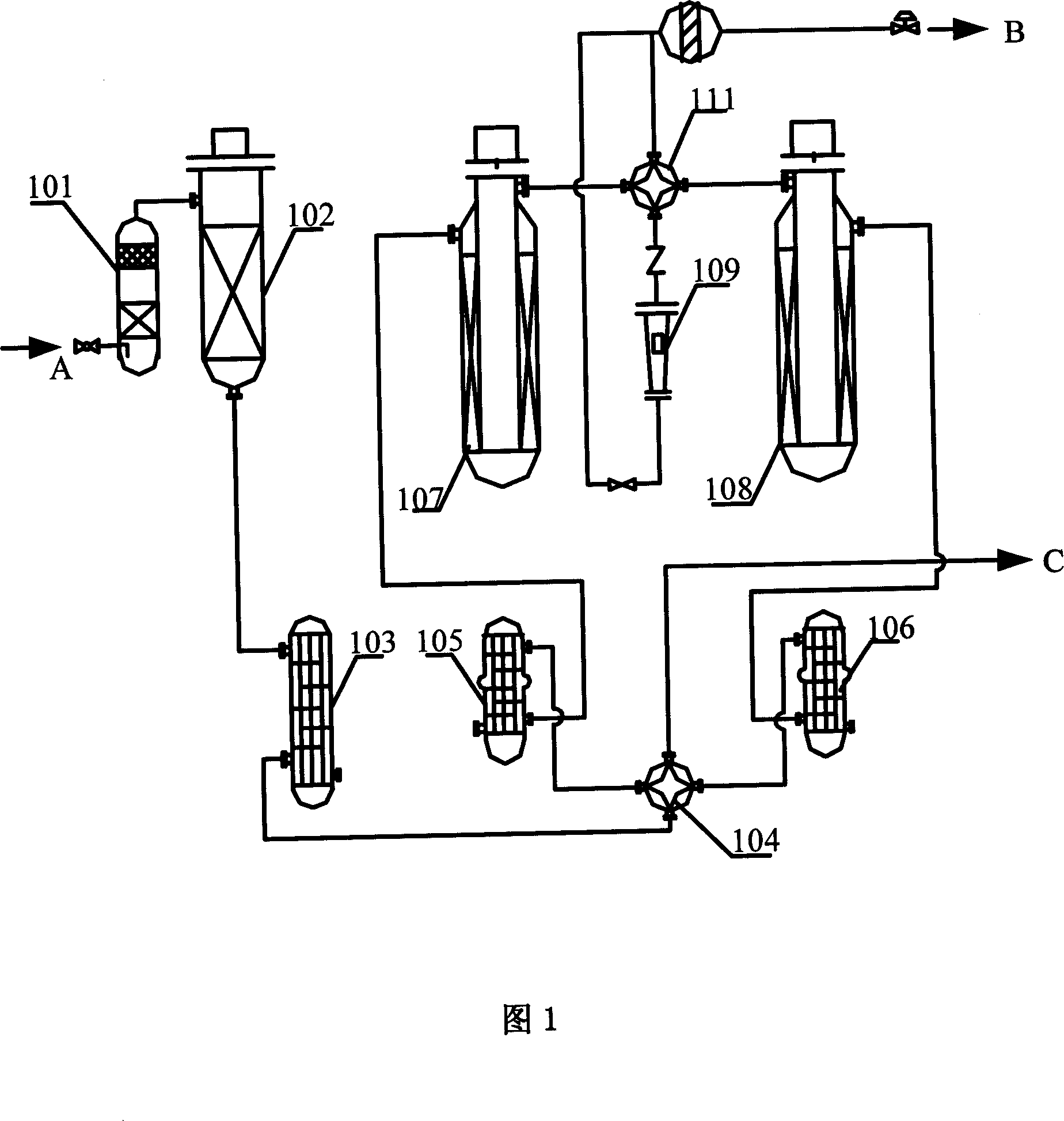

[0021] The hydrogen containing saturated water vapor obtained after electrolysis of water enters the zero-emission three-tower continuous hydrogen purification process system of the present invention. Firstly, the free ionized water is separated and removed by the steam-water separator 1, and then enters the deoxidizer 2 equipped with a palladium-platinum bimetallic deoxidation catalyst to remove impurity oxygen, and then enters the hydrogen cooling condenser 3 to complete the first-level dehumidification, and then performs continuous purification treatment.

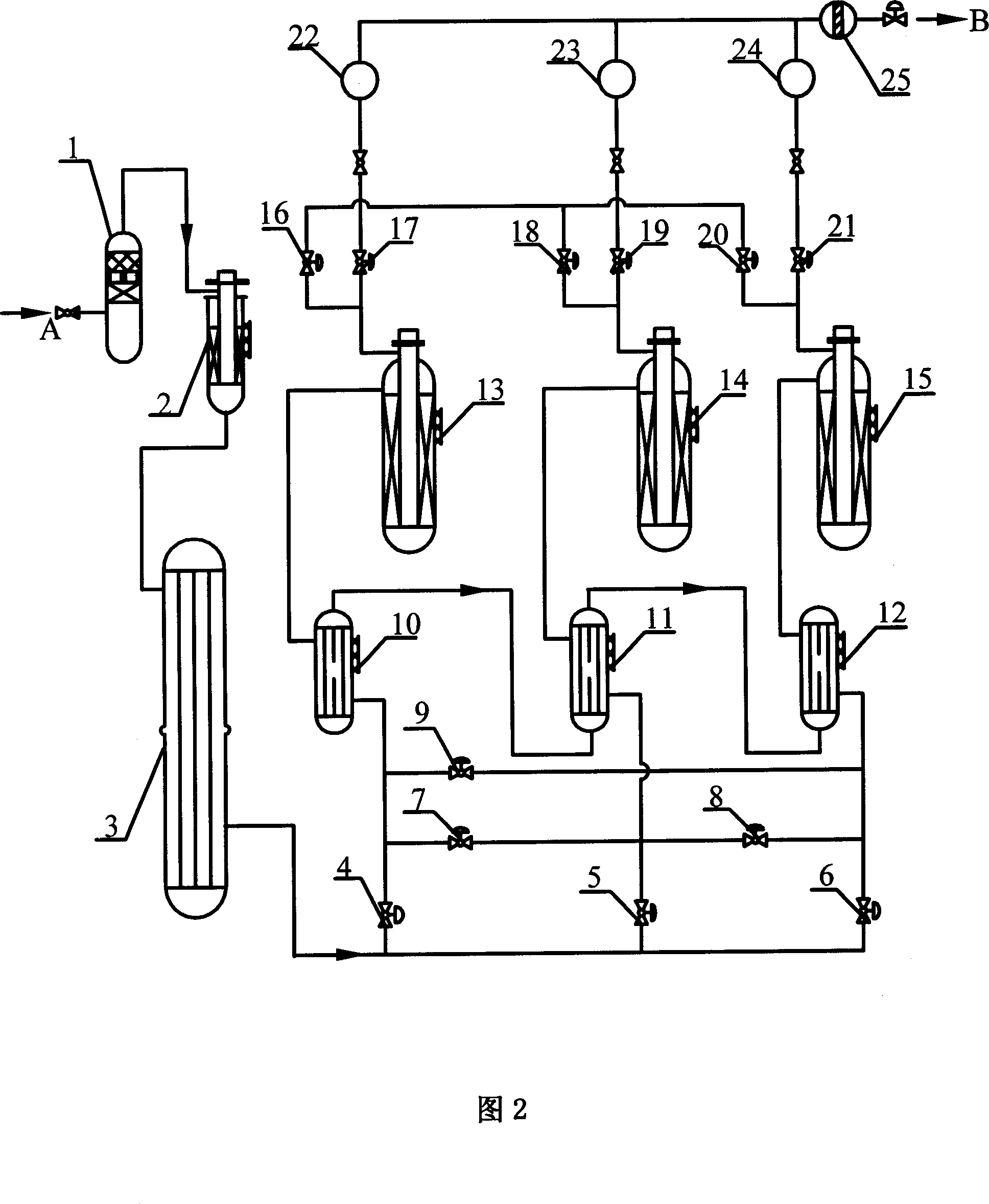

[0022] As shown in Figure 2, the present invention uses three drying towers (the No. I tower 13, the No. II tower 14, the No. III tower 15), three regeneration coolers (the No. I regeneration cooler 10, the II regeneration cooling device 11, III regenerative cooler 12) and corresponding inlet and outlet valves (I automatic valve 4, II automatic valve 5, III automatic valve 6, IV automatic valve 7, V automatic valve 8, VI ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com