Toughening composite material lamination board and method for making same

A composite material layer and plywood technology, applied in the direction of chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the difficulties in composite material construction, the deterioration of the toughening matrix process, and the increase in material costs and process costs, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] First prepare the low-toughness composite material as matrix material: T300 / epoxy resin prepreg (epoxy resin composition is AG-80: E-54: DDS=60: 40 with TB-1 type winding prepreg machine wet method : 40), according to [45 / 0 / -45 / 90] 4S way of quasi-isotropic layup. Curing and molding in an autoclave, molding process: vacuumize the whole process to 0.095MPa, heat up from room temperature to 130°C, keep warm for 0.5h, pressurize to 0.55MPa~0.6MPa, then heat up to 180°C for 2h, then heat up to 200 ℃ for 2 hours, and finally cooled naturally to below 60 ℃. The heating rate is 1.0°C / min~2.0°C / min.

[0064] Then prepare the toughened film: dissolve polyethersulfone (PES) in tetrahydrofuran, prepare a 5% solution, and evenly coat the upper surface of the industrial film placed horizontally, and obtain a toughened film after the solvent volatilizes naturally. The areal density is about 20g / m 2 . The toughened film after drying is taken off from the industrial film, rolled u...

Embodiment 2

[0069] Preparation of low-toughness composite materials in active aircraft structures: This material is provided in the form of commercial prepreg (T300 / NY9200G), the basic resin system is epoxy resin, and the specific formula is unknown. Follow [45 / 0 / -45 / 90] 4S The method is quasi-isotropic layering, curing and molding in an autoclave, and the molding process: vacuumize the whole process to 0.095MPa, heat up from room temperature to 80°C, keep warm for 0.5h, pressurize at 130°C to 0.55MPa~0.6MPa, and continue to keep warm After 0.5 hours, raise the temperature to 130°C for 1 hour, then raise the temperature to 180°C for 2 hours, then raise the temperature to 200°C for 2 hours, and finally cool it down to below 60°C and leave the tank. The heating rate is 1.0°C / min~2.0°C / min.

[0070] Prepare a toughening layer again: polyaryletherketone (PAEK) is dissolved in tetrahydrofuran / dimethylformamide mixed solvent to prepare a 20% solution. This solution was cast and knife-coated o...

Embodiment 3

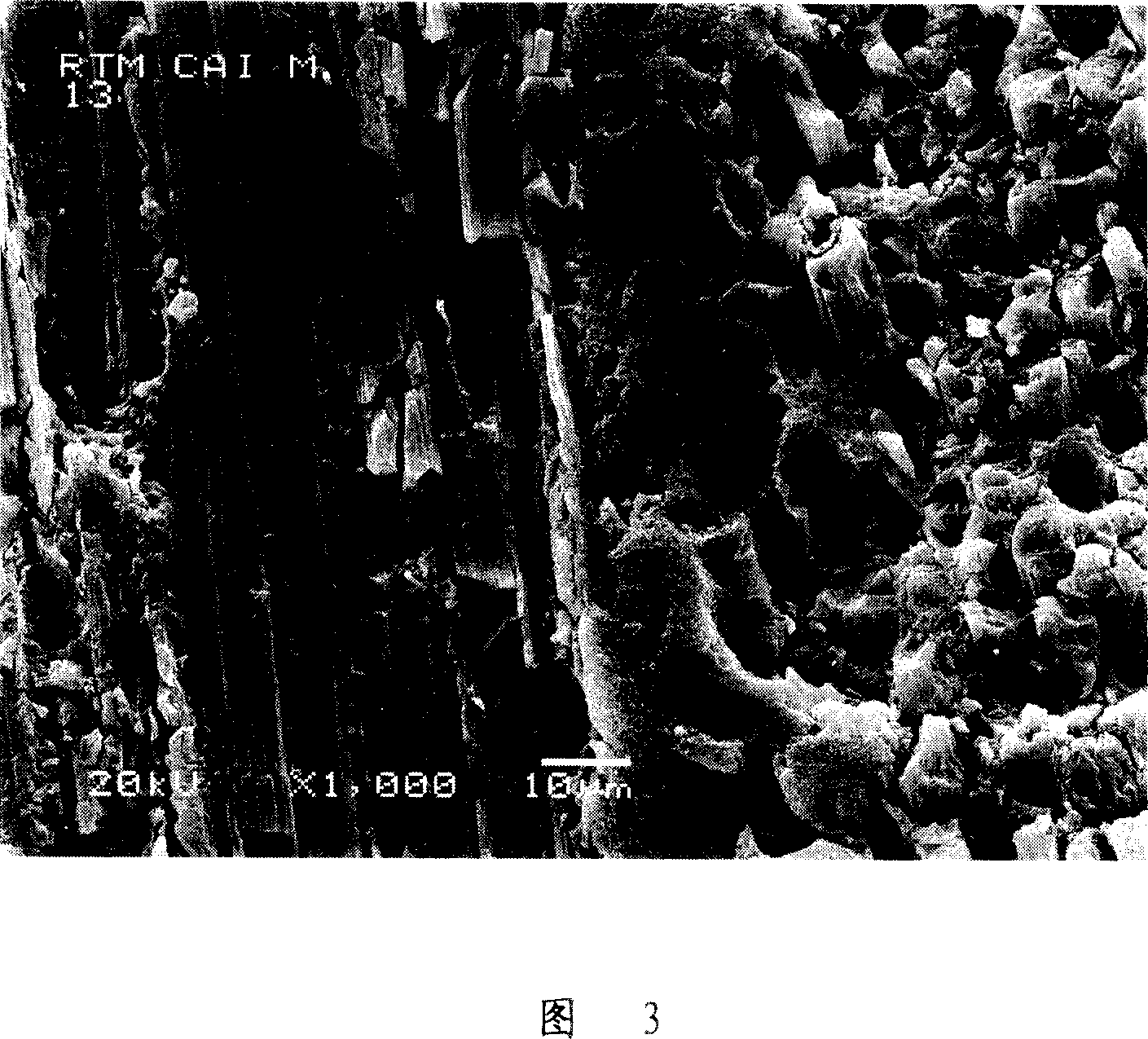

[0075] First prepare the low-toughness bismaleimide composite material as the matrix material: T700 / bismaleimide prepreg is prepared by wet method with TB-1 winding prepreg machine, according to [45 / 0 / -45 / 90] 2S The method is quasi-isotropic layering, autoclave curing molding, molding process: from room temperature to 180°C, when the temperature rises to 120°C, pressurize to 0.4MPa, when the temperature rises to 160°C, pressurize to 0.7MPa; Keep warm for 3 hours at 180°C, continue to heat up to 200°C for 5 hours, vacuumize the whole process, and finally cool naturally below 60°C to open the mold. The heating rate is 1.5°C / min to 2.0°C / min. The prepared composite material plate was cut into 89mm×55mm samples, and subjected to post-impact compression test (test specifications refer to QMW CAI), the impact energy was 2J / mm, and the CAI value was 180MPa.

[0076] Prepare the toughening layer again: dissolve polyaryletherketone (PAEK) and bismaleimide (BMI) in a mixed solution of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com