Smog discharge continuous monitor system

A monitoring system and flue gas emission technology, applied in the direction of color/spectral characteristic measurement, instruments, analytical materials, etc., can solve the problems of reducing the trouble-free service time of the system, complex system structure, low reliability, etc., and achieve low engineering maintenance. , the system structure is simple, the effect of reducing maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

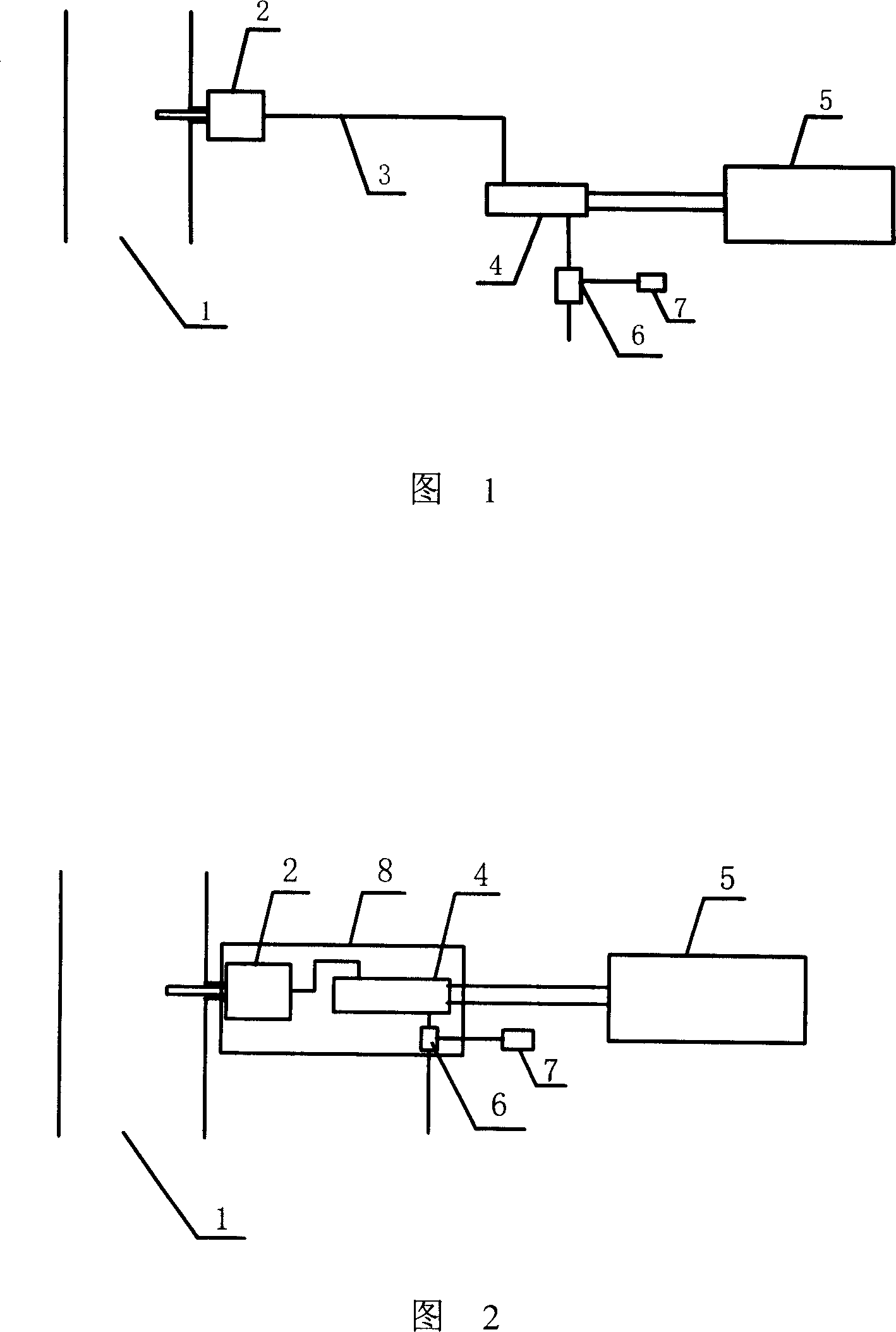

[0022] As shown in Figure 1, a flue gas emission continuous monitoring system is used for continuous monitoring of flue gas emission pollution sources, including sampling pretreatment device 2, heating pipeline 3, heating gas measuring chamber 4, measuring device 5 and gas extraction The device also includes a pressure sensor (not shown) mounted on the heated gas measuring chamber 4. The sampling pretreatment device 2 is installed on the measured gas pipeline 1 . Both ends of the heating line 3 are connected to the sampling pretreatment device 2 and the heating gas measuring chamber 4 . Described measuring device comprises a set of ultraviolet absorption spectrum analysis device 5, oxygen sensor (the present embodiment adopts zirconia sensor), and described ultraviolet absorption spectrum analysis device 5 is connected with heating gas measurement chamber by optical fiber, and described oxygen sensor (not shown Out) installed on the heating gas measuring chamber 4. The air e...

Embodiment 2

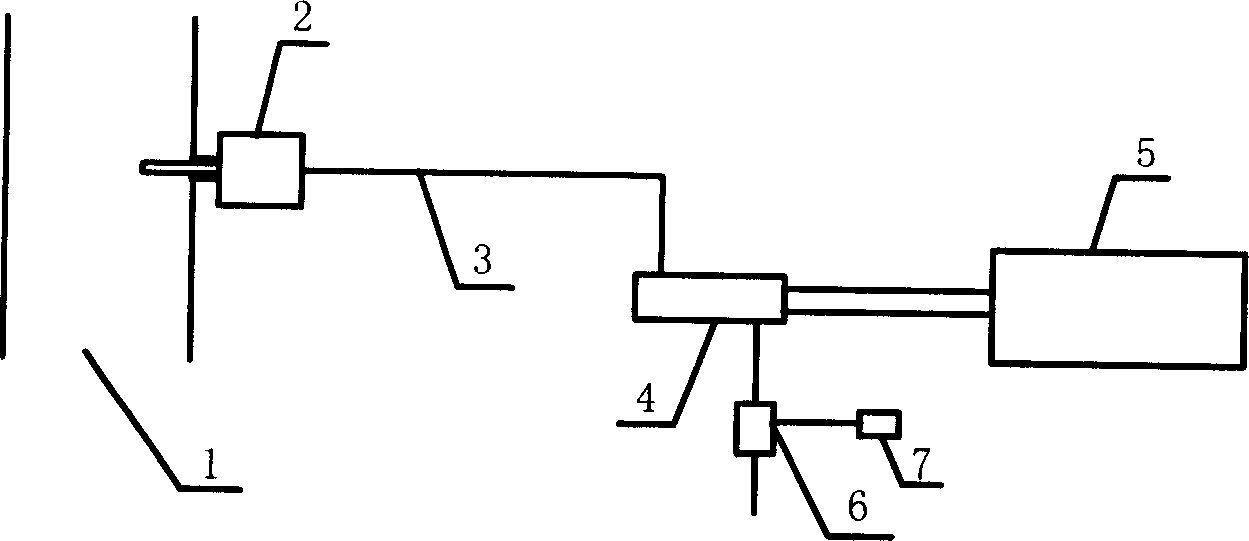

[0025] As shown in Figure 2, a continuous monitoring system for flue gas emission is used for continuous monitoring of flue gas emission pollution sources, including a sampling pretreatment device 2, a heating gas measurement chamber 4, a measuring device 5 and an extraction device. The sampling pretreatment device 2 is installed on the measured gas pipeline 1 . The sampling preprocessing device 2 is connected with the heating gas measuring chamber 4 and installed in a heating device 8 . The measuring device includes a set of ultraviolet absorption spectroscopic analysis device 5 and an oxygen sensor (a zirconia sensor is used in this embodiment), and the oxygen sensor is installed on the heating gas measuring chamber 3 . The air extraction device for extracting the flue gas in the pipeline under test is installed after the heating gas measurement chamber, including a jet device 6 and a gas source 7 (compressed air is used in this embodiment), and the jet device 6 is installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com