Filter and filter aggregate

A technology of filters and aggregates, applied in membrane filters, filtration separation, dispersed particle filtration, etc., can solve the problems of not being able to sufficiently reduce pressure loss and capture particulate matter, opening ratio affects circulation, and pressure loss increases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

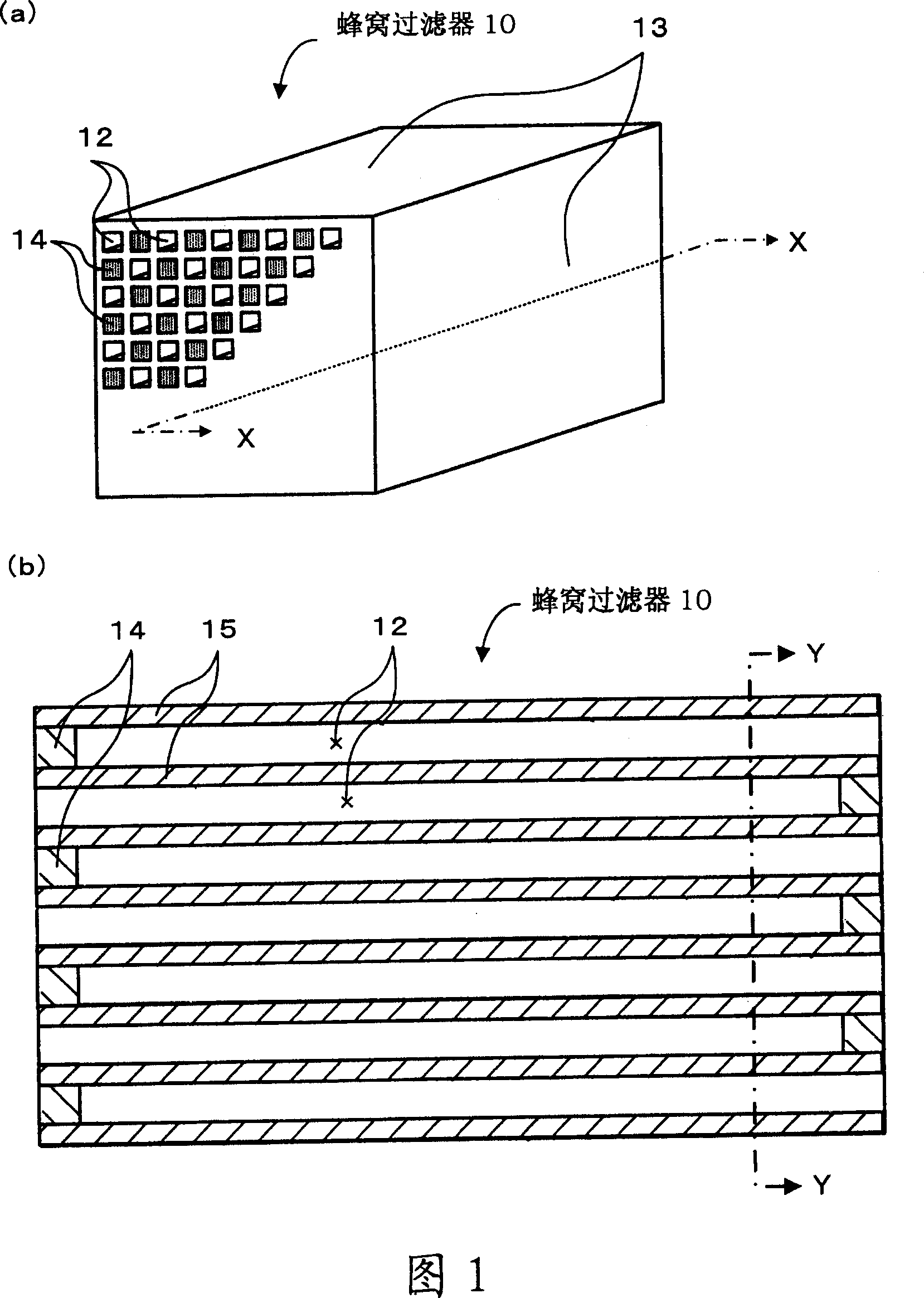

[0052] First, 6720 parts by weight of α-type silicon carbide powder (average particle diameter 22 μm) as coarse silicon carbide, 2880 parts by weight of α-type silicon carbide powder (average particle diameter 0.5 μm) as particulate silicon carbide, 980 parts by weight Acrylic resin particles (average particle size 20 μm) and 2970 parts by weight of water as a pore-forming agent are mixed, and 1050 parts by weight of methyl cellulose as an organic binder, 500 parts by weight of glycerol as a plasticizer , and 230 parts by weight of a lubricant (trade name unilube (UNILUBE); manufactured by NOF Corporation), were kneaded to obtain clay. Table 1 summarizes the raw materials of the honeycomb filter 10 in Experimental Example 1, the average particle size of each raw material, and the numerical values of the added amount. In addition, Table 1 also collectively shows the contents related to Experimental Examples 2 to 34 described later. Next, the clay is extruded using an extrusi...

experiment example 2~34

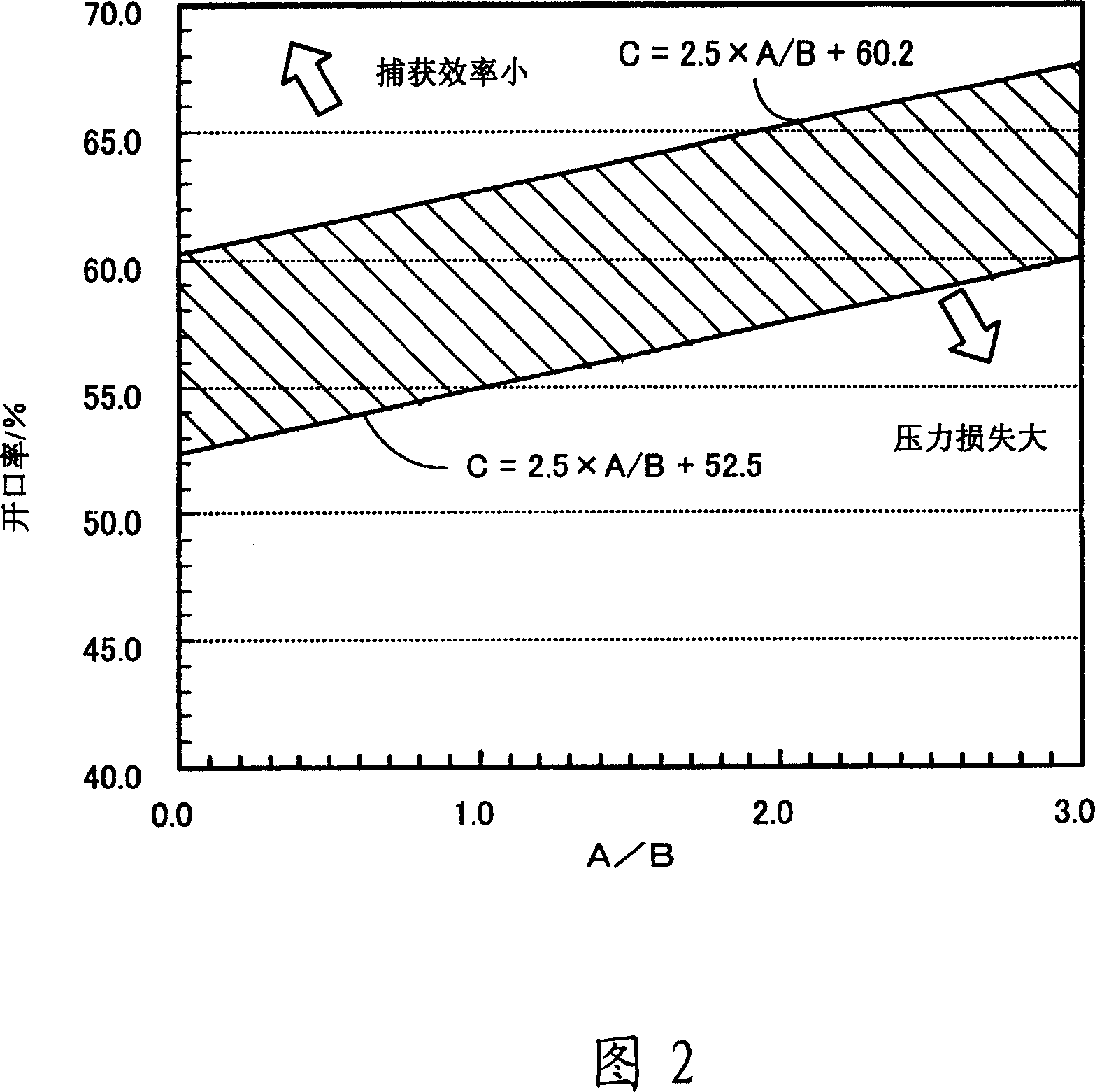

[0058] Mix the raw materials according to the amount of addition shown in Table 1, and design the opening ratio C, wall thickness, and pore density shown in Table 2. In addition, use the same method as Experimental Example 1 to make experimental examples 2 to 34. Honeycomb filter 10.

[0059] [Measurement of Pore Diameter / Porosity]

[0060] The pore diameter / porosity measurement of Experimental Examples 1-34 was performed. As a measuring machine, an automatic porosity measuring instrument AutoPore III9405 manufactured by Shimadzu Corporation was used, and the measurement was performed by a mercury porosimetry in accordance with JIS-R1655. Specifically, the portion of the honeycomb filter 10 that does not include the plugged portion 14 is cut into a cube with a side of about 0.8 cm, ultrasonically cleaned with ion-exchanged water, dried, and measured using the above-mentioned measuring machine at a thickness of 0.1 μm to 360 μm. Measure within the measuring range. In the ran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com