Pigment dispersant and pigment composition, pigment dispersion and printing ink using the same

A pigment dispersant and pigment composition technology, applied in the field of pigment dispersants, can solve the problems of no effect, no effect, no sufficient effect, etc., and achieve the effect of good color tone and excellent fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

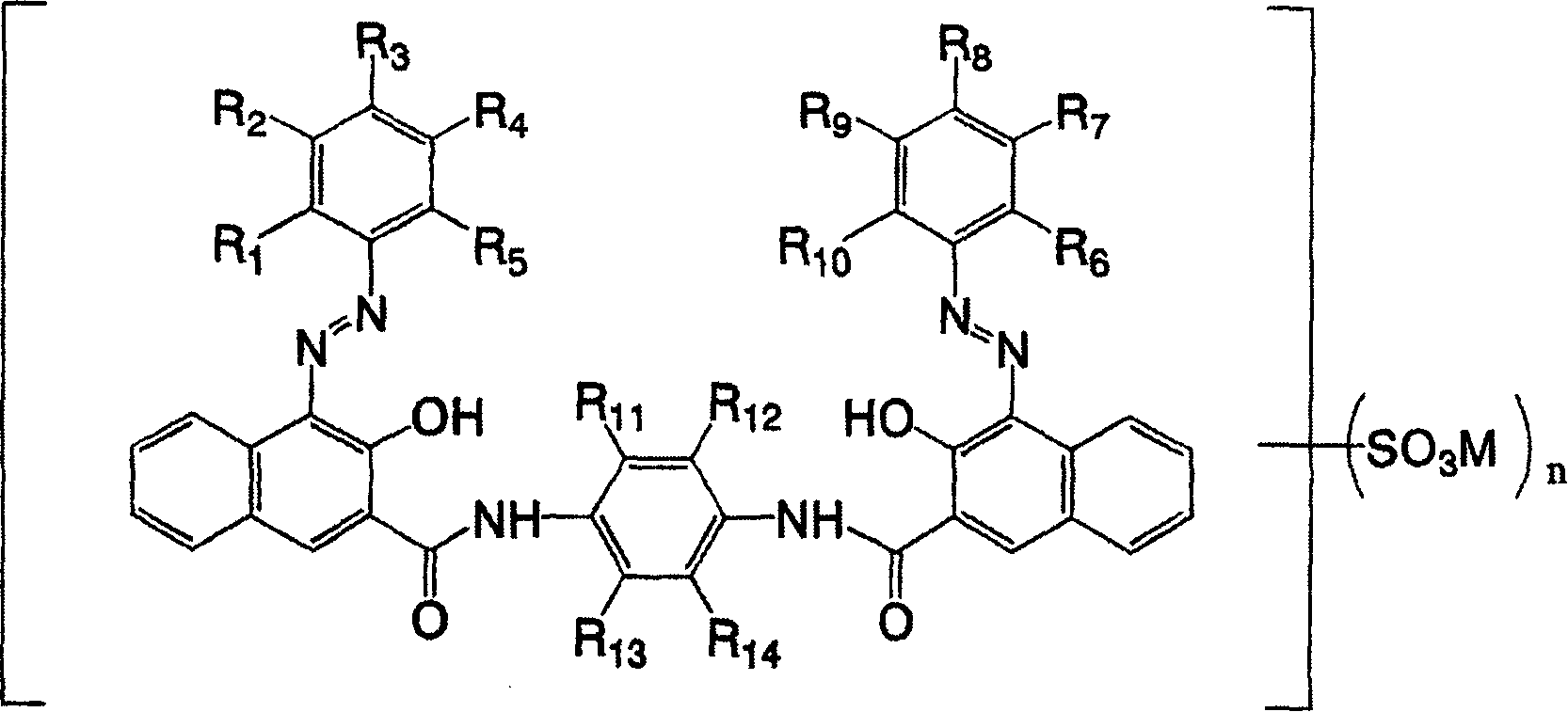

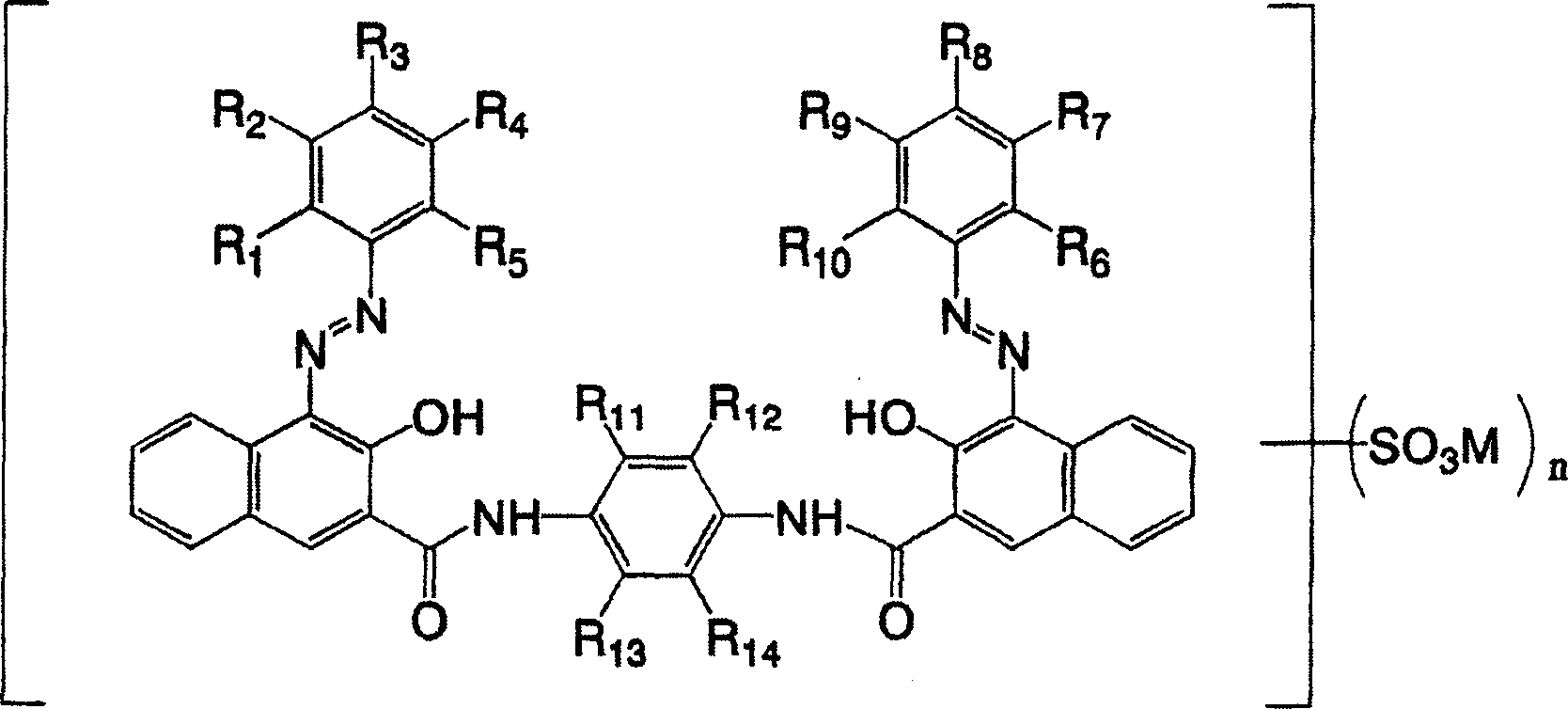

[0059] Add 15 parts of Pigment Red 166 to 300 parts of 99% sulfuric acid, and react at 25°C for 3 hours. This reaction solution was poured into 3000 parts of ice water, stirred, filtered, and washed with 2% hydrochloric acid aqueous solution. After the resulting filter cake was slurried with 700 parts of water, the pH was adjusted to 9 with sodium hydroxide. Next, it was heated to 60° C., 58 parts of 10% aluminum sulfate aqueous solution was added, stirred at 60° C. for 1 hour, filtered, washed with water, and dried to obtain 18 parts of pigment dispersant (a). The average number of substituents of the sulfonic acid group was 1.8.

manufacture example 2

[0061] Change pigment red 166 to pigment red 214, at the same time, change the reaction temperature from 25 ℃ to 30 ℃, and change 58 parts of 10% aluminum sulfate aqueous solution into 29 parts of 10% calcium chloride aqueous solution, in addition, it is the same as the production example 1 in the same manner to obtain 17 parts of pigment dispersant (b). The average number of substituents of the sulfonic acid group is 1.5.

manufacture example 3

[0063] Change pigment red 166 to pigment red 144, simultaneously, change reaction temperature from 25 ℃ to 20 ℃, and change 58 parts of 10% aqueous solution of aluminum sulfate into 33 parts of 10% aqueous solution of ferrous sulfate, in addition, it is the same as the production example 1 in the same manner to obtain 18 parts of pigment dispersant (c). The average number of substituents of the sulfonic acid group was 1.2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com