Hydraulic engine plunger pump

A hydraulic motor and plunger pump technology, applied in the field of axial plunger pumps, can solve the problems of high noise and external leakage of the hydraulic power unit, and achieve the effects of reliable sealing, convenient cooling and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

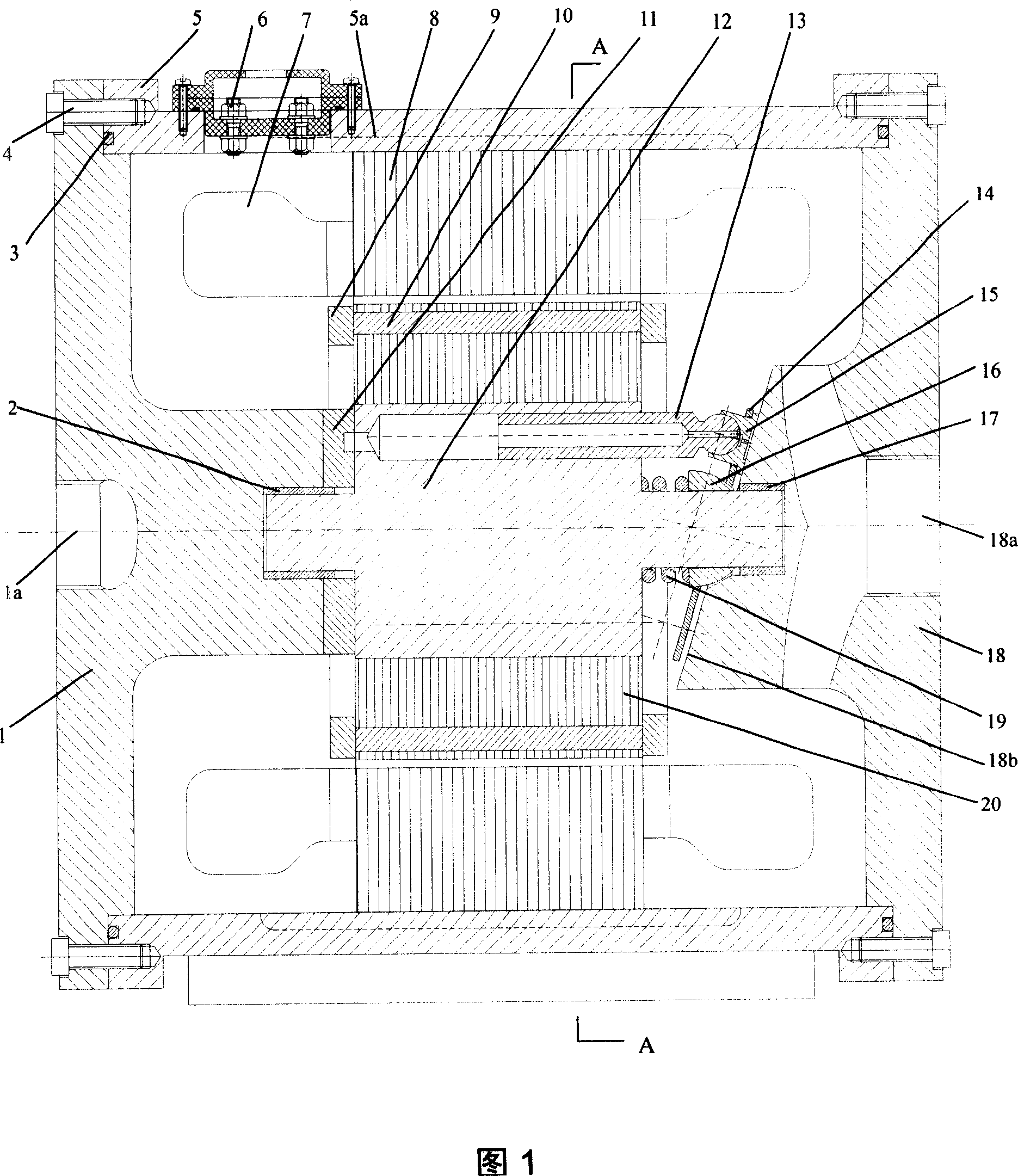

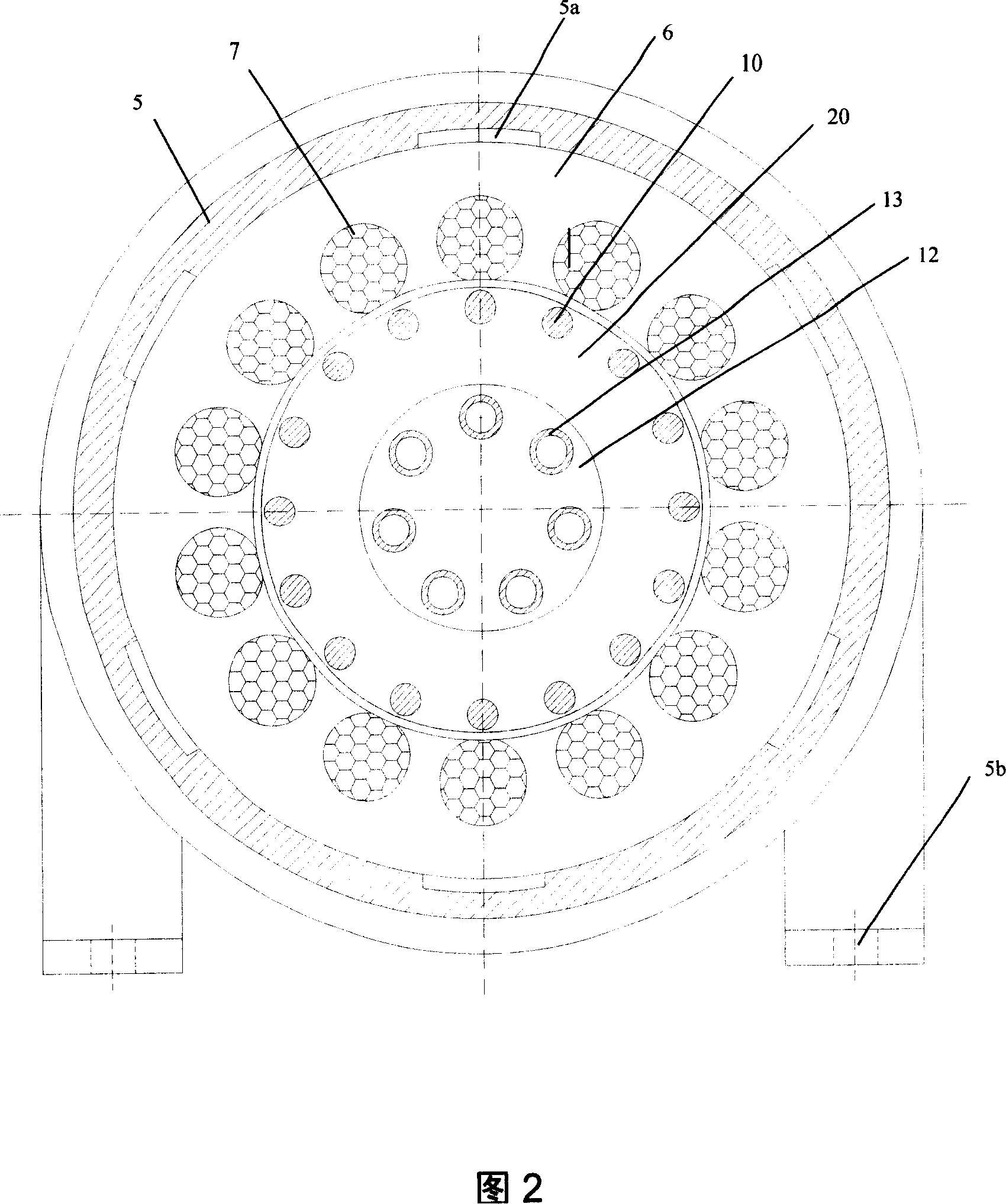

[0009] As shown in Figure 1 and Figure 2, a motor stator 8 is installed in the pump casing (5), a motor winding 7 is housed in the motor stator 8, a motor rotor 20 is arranged inside the motor stator 8, and rotor guides are evenly distributed in the motor rotor 20. Bar 10 has an end ring 9 on both sides of its end face, and a cylinder body 12 is installed in the inner hole of the motor rotor 20, and the cylinder body 12 is supported on the left pump cover 1 through the first bearing (2) and the second bearing (17). 1. Between the right pump cover 18, the right pump cover 18 is provided with an oil inlet 18a, the left pump cover 1 is provided with an oil outlet 1a, and the inner surface of the pump casing 5 is evenly distributed with a plurality of axial grooves 5a, A junction box 6 is set on the pump casing 5, a flow distribution plate 11 is arranged between the left pump cover 1 and the end faces of the cylinder body 12, and a plurality of plungers 13 are evenly distributed in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com