Engine auxiliary drive for a motor vehicle with a toothed-gear drive

A technology of auxiliary transmission and gear transmission, which is applied in the direction of transmission device, friction transmission device, hoisting device, etc., can solve the problems of insufficient capacity to withstand high load, uneconomical use, high price, etc., to reduce the risk of overload, Good optimization, optimize the effect of tooth thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

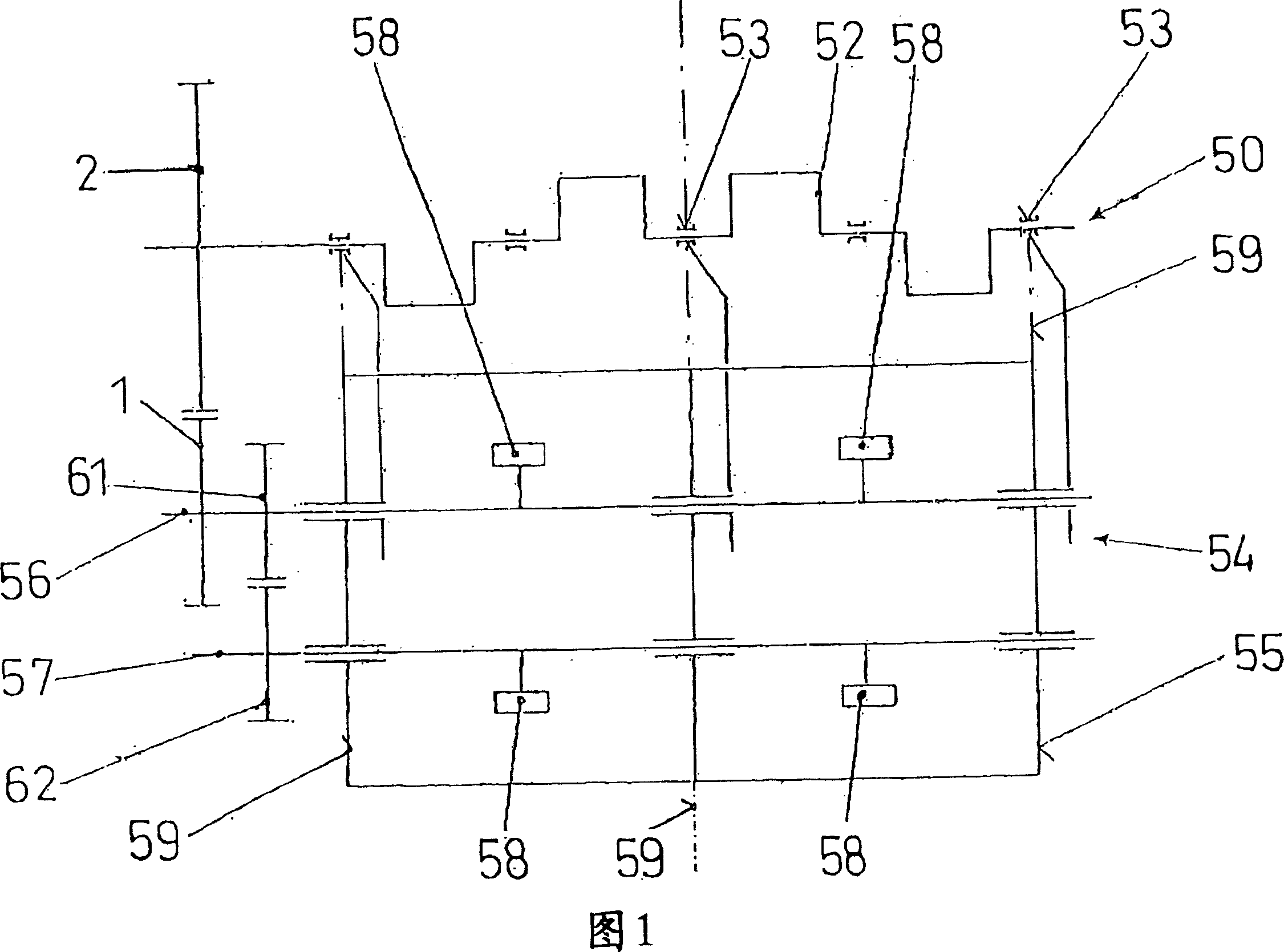

[0029] FIG. 1 shows only a reciprocating piston engine 50 symbolically by its crankshaft 52 and its main bearings 53 . The main bearing 53 represents the whole engine block, which can be designed as a tunnel structure or as an independent bearing support. A mass balancing device secured to the engine block below the crankshaft 52 is indicated generally at 54 . It consists of a balancing device housing 55 and two balancing shafts 56 , 57 with counterweights 58 rotating in opposite directions therein. The dashed line indicates the normal plane 59 through the main bearing 53 . The bearings of the mass balance device 54 lie in this plane. The balance shafts 56, 57 are driven by a gear 2 which is rotationally fixedly connected with the crankshaft 52 through the transmission gear 1, and the synchronous gears 61, 62 are used to make the balance shafts 56, 57 in opposite directions and at the same speed.

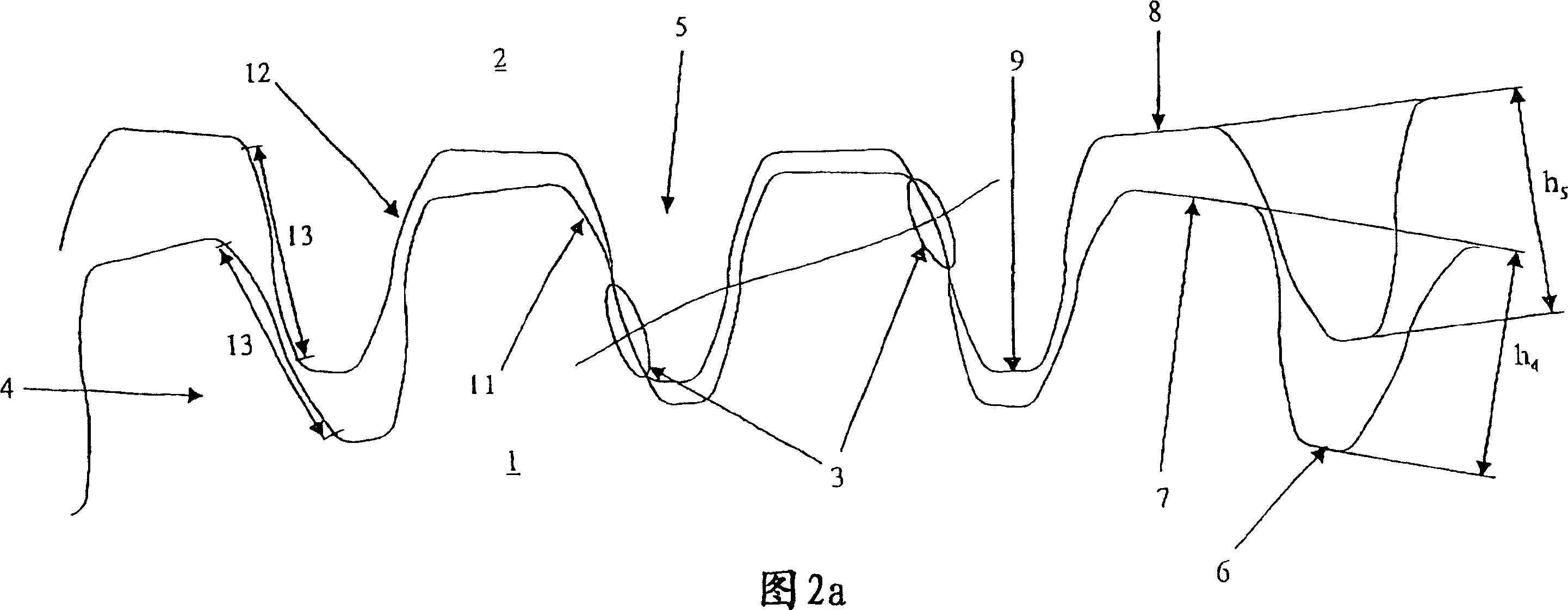

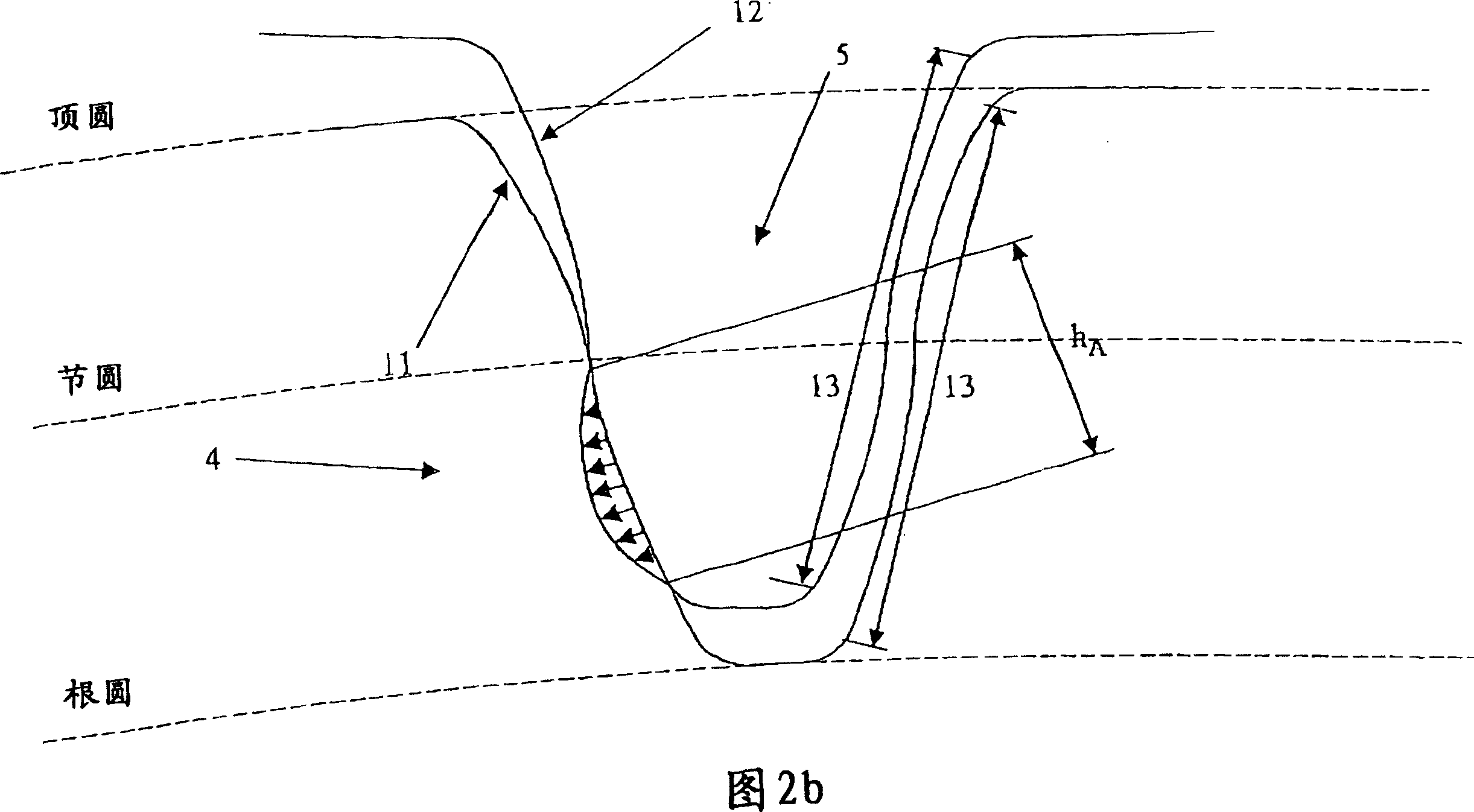

[0030] 2a and 2b show the toothing geometry of the tooth pairing of the gear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com