Marine tow line array double-wing automatic fixing depth device

A towed linear array and double-wing technology, which is applied in the field of automatic depth determination devices for towed cable arrays in the sea for seismic exploration, can solve the problems of poor reliability of the driving mechanism, insensitive wing plate movements, and inconvenient tow cable connections, etc., and achieve weight reduction, Lightweight and good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

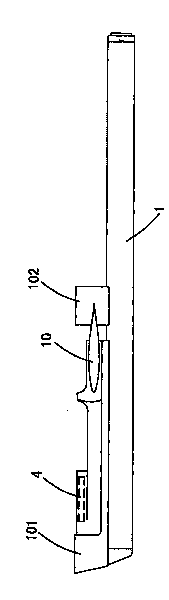

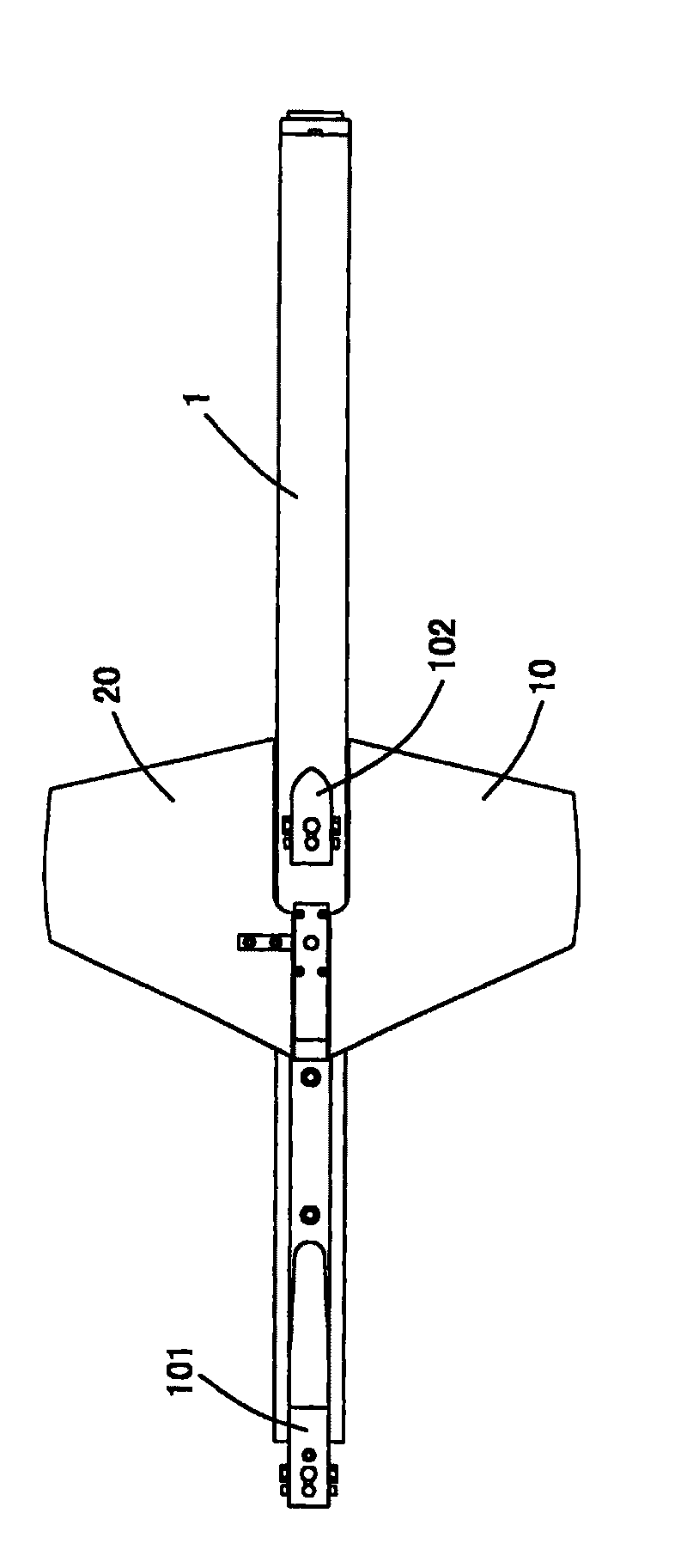

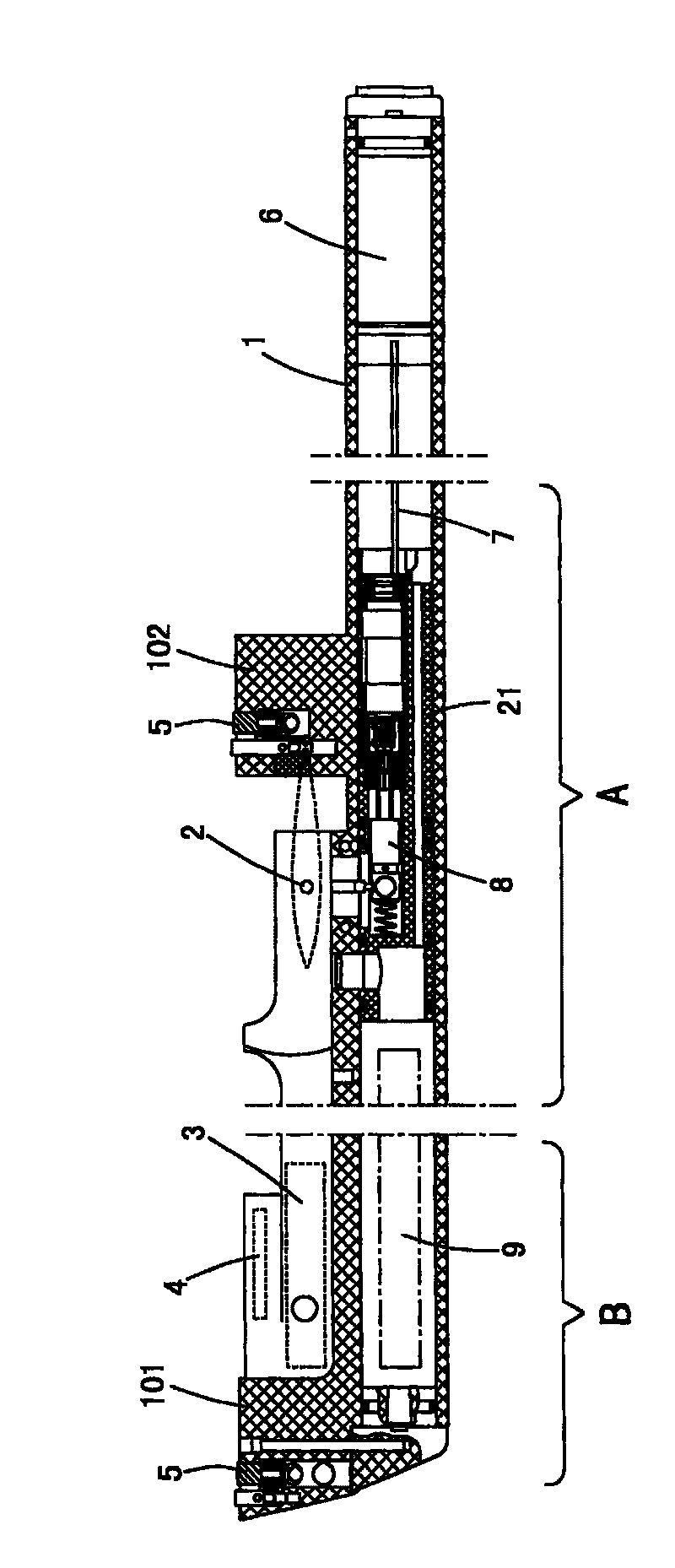

[0040] Labels in the figure:

[0041] 1. Pressure-resistant shell 101. Connection platform 102. Connection platform 103. Waist hole

[0042] 2. Flap mounting shaft 3. Depth sensor 4. Communication coil 5. Locking mechanism

[0043] 6. Magnetic compass module 7. Communication and control module 8. Driving mechanism 9. Battery pack

[0044] 10. Wing plate 11. Encoder 12. Motor 13. Reducer

[0045] 14. Coupling 15. Screw 151. Main shaft 16. Nut

[0046] 17. Rod seat 18. Top spring 19. Swing rod 20. Wing plate 21. Sleeve

[0047] 211. Wiring hole 22. Sealing cylinder 221. Rear port 222. Inner chamber

[0048] 223. Front orifice 224. Inner hole 225. Inner hole 226. Groove

[0049] 23.Seal assembly 24.Bearing 25.Bearing 26.Sealing ring

[0050] 27. Seal ring 28. Shaft seat 29. Screw 30. Screw

[0051] 31. Lock bolt 311. Wedge head 312. Bottom hole

[0052] 32. Bolt 321. Big head 33. Belleville spring

[0053] 34. Rotating rod 341. Eccentric cylinder 342. Handle 343. Handle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com