Semiconductor laser shaper

A shaping device and laser technology, applied in the field of lasers, can solve the problems of small adjustment tolerance of cylindrical lenses, difficult focal length processing, complex structure, etc., and achieve the effects of small light energy loss, convenient collimation and coupling, and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

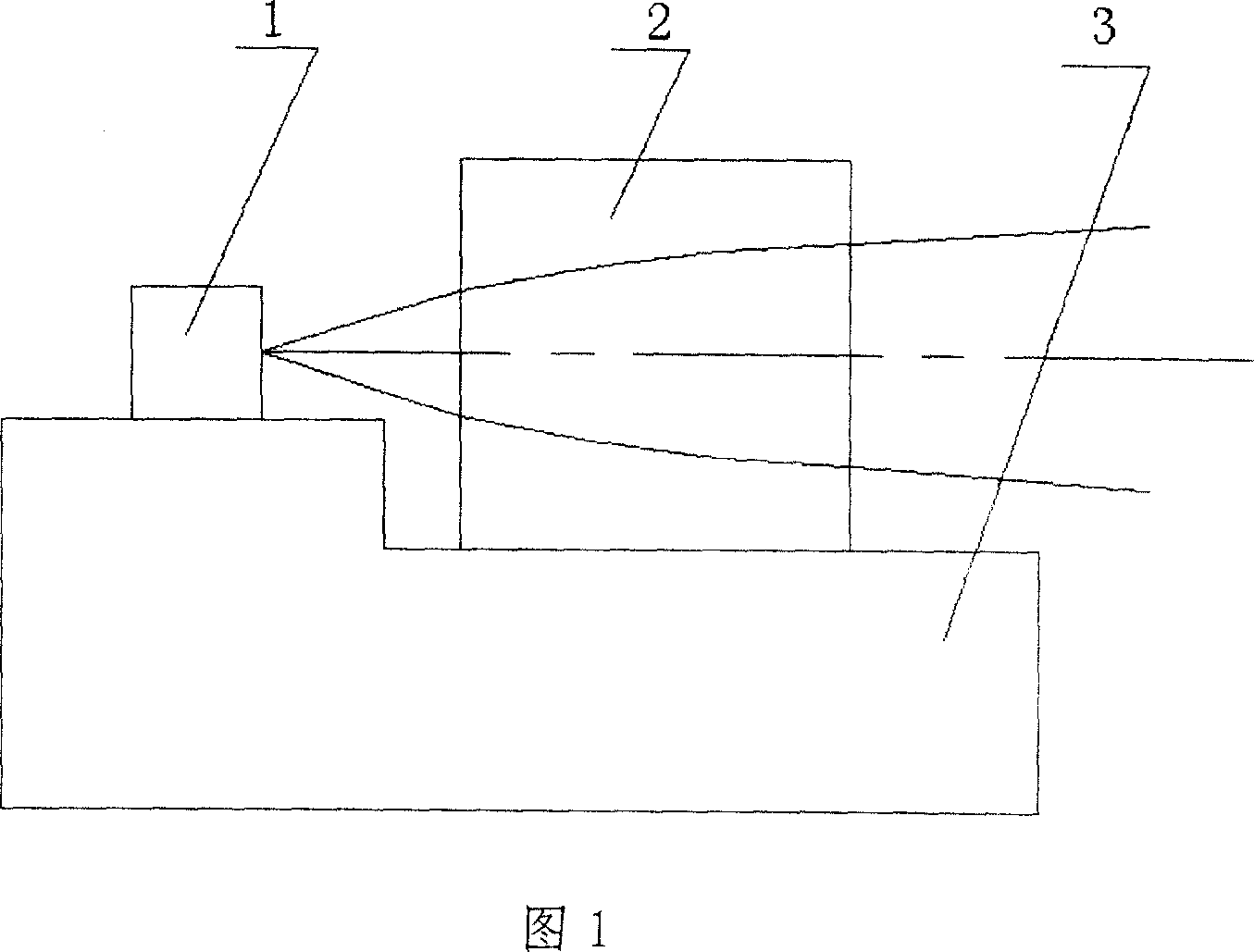

[0029] In FIG. 1 , the semiconductor laser shaping device of this embodiment is composed of a bracket 3 , a semiconductor laser 1 , and a one-dimensional gradient index lens 2 connected together.

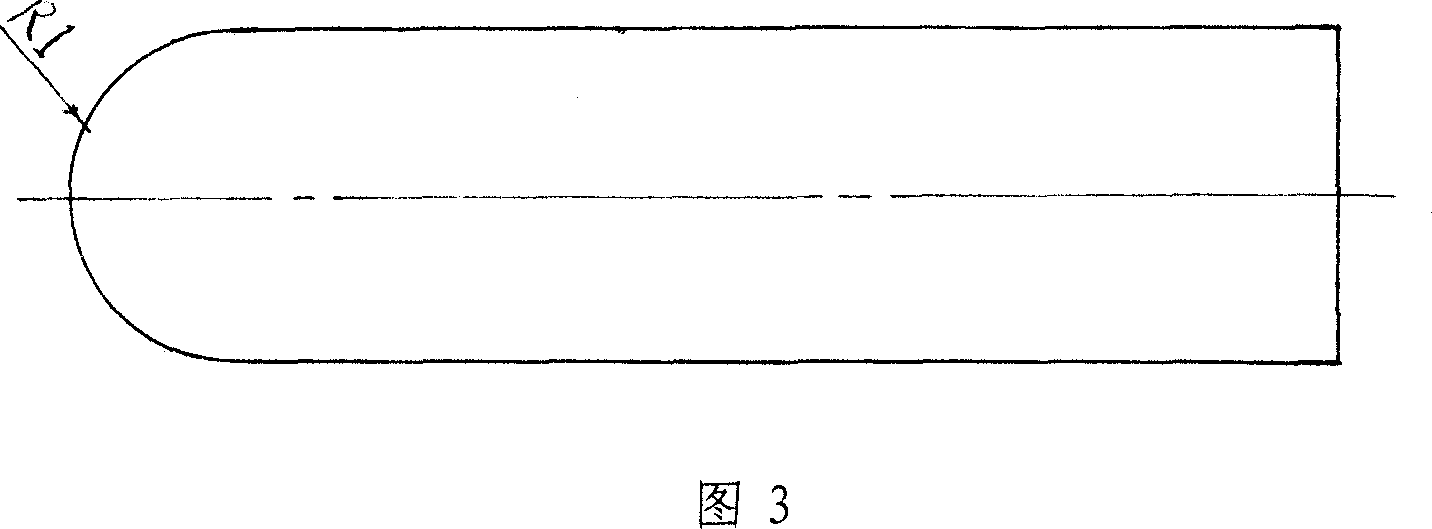

[0030] A semiconductor laser 1 is fixedly installed on the bracket 3 , the model of the semiconductor laser 1 in this embodiment is QL65D5SA, the wavelength is 650nm, and its light emitting area is 5um×2um. On the bracket 3, the direction in which the semiconductor laser 1 emits the laser beam is placed horizontally and fixedly installed with a one-dimensional gradient refractive index lens 2. The one-dimensional gradient refractive index lens 2 is a rectangular flat plate lens, and this lens has gradient refraction only in the thickness direction of the lens. rate, the thickness of the one-dimensional gradient index lens 2 is 0.3mm, the length of the light is 1.5mm, the width is 2mm, and the focusing constant is 2.51. The laser incident surface of the one-dimensional gradient ind...

Embodiment 2

[0035] In this embodiment, the one-dimensional gradient index lens 2 is a rectangular flat plate lens, the thickness of the one-dimensional gradient index lens 2 is 0.1mm, the length of light passing is 0.1mm, the width is 0.1mm, and the focusing constant is 7.5, n 0 is 1.5. The laser surface of the one-dimensional gradient index lens 2 is a plane perpendicular to the laser fast axis direction, the laser exit surface is a plane perpendicular to the laser fast axis direction, and the distance between the one-dimensional gradient index lens 2 and the semiconductor laser 1 is 0.05mm. Other components and the coupling relationship of the components are the same as in Embodiment 1.

Embodiment 3

[0037]In this embodiment, the one-dimensional gradient index lens 2 is a rectangular flat plate lens, the thickness of the one-dimensional gradient index lens 2 is 2mm, the light transmission length is 9.5mm, the width is 8mm, and the focusing constant is 0.36, n 0 is 1.7. The laser incident surface of the one-dimensional gradient index lens 2 is a plane perpendicular to the fast axis direction of the laser, the laser exit surface is a plane perpendicular to the fast axis direction of the laser, and the distance between the one-dimensional gradient index lens 2 and the semiconductor laser 1 is 2.5mm . Other components and the coupling relationship of the components are the same as in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com