Composite filler for biological filtering bed

A technology of composite packing and biological filter bed, which is applied in chemical/physical process, chemical/physical/physical chemical process, dispersed particle separation, etc. It can solve the problems of unstable natural packing structure and poor pollutant removal effect, and achieve saving Facility investment costs and labor costs, beneficial to growth and reproduction, and the effect of reducing compaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

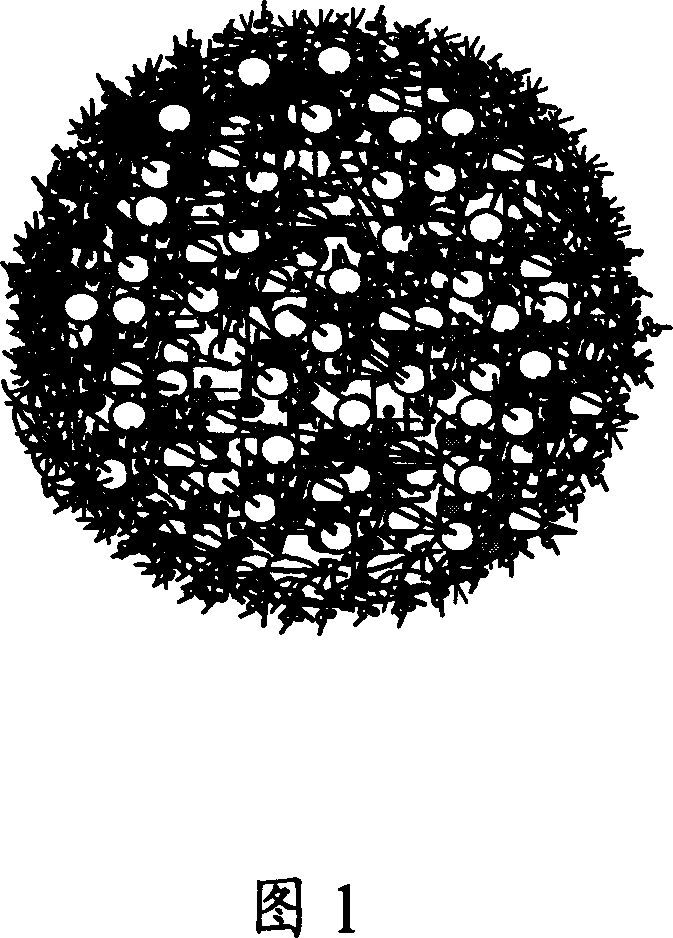

Image

Examples

Embodiment 1

[0028] Embodiment 1: Adhesive brown fiber-peat / perlite spherical composite filler

[0029] 1. Filling production

[0030] (1) Lay the brown fiber silk criss-cross first, spray natural rubber latex to bond it into a support net with a thickness of 10mm, and control the density of the brown fiber silk net to 80-160kg / m 3 . Then the palm fiber net was punched and shaped for 8 minutes at 80-140° C. to make a brown fiber hemispherical surface with an outer diameter of 50 mm. At this time, the thickness of the spherical shell was reduced to 6-8 mm.

[0031] (2) get above-mentioned brown fiber web and the leftover material after utilizing step (1) processing in addition to be processed into the brown fiber block B of 10mm square.

[0032] (3) Take peat and perlite powder with a volume ratio of 2:3, and add self-made BFP-A01 type bacterial agent according to the total volume ratio of 0.15%, which contains efficient degradation of trimethylamine, organic sulfur and other odor polluta...

example 2

[0041] Example 2: Adhesive vinylon and polyamide silk - granular organic fertilizer - expanded vermiculite - bamboo charcoal composite filler

[0042] 1. Filling production

[0043] (1) Get ready commercial organic compound fertilizer A, namely commercially available φ3mm columnar granule organic fertilizer produced by Huanfa Organic Fertilizer Company in Zhengding County, Hebei Province, which is produced by fermenting chicken manure.

[0044] (2) Prepare expanded vermiculite B with a particle size of 3-6 mm and crushed bamboo charcoal C with a particle size of 3-10 mm.

[0045] (3) Mix the above-mentioned three raw materials of A, B and C, each with one-third equal volume, and dry naturally for later use.

[0046] (4) Cut the polyamide yarn of the polyvinylon yarn with a diameter of 0.5 mm into a length of 20 to 100 cm for later use.

[0047] (5) Take the above-mentioned ratio of 68.1% vinylon and 31.9% polyamide and mix them evenly, lay up a support net with a thickness o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com