Biomass graded temperature-control slow pyrolysis process and its system

A biomass and rapid heating technology, applied in the fields of biofuels, petroleum industry, special forms of dry distillation, etc., can solve the problems of fast heating speed, reducing the gasification efficiency of gasification system, and the heating speed cannot be strictly controlled, so as to ensure the heating temperature. and heating speed, high comprehensive utilization efficiency, and the effect of improving comprehensive utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

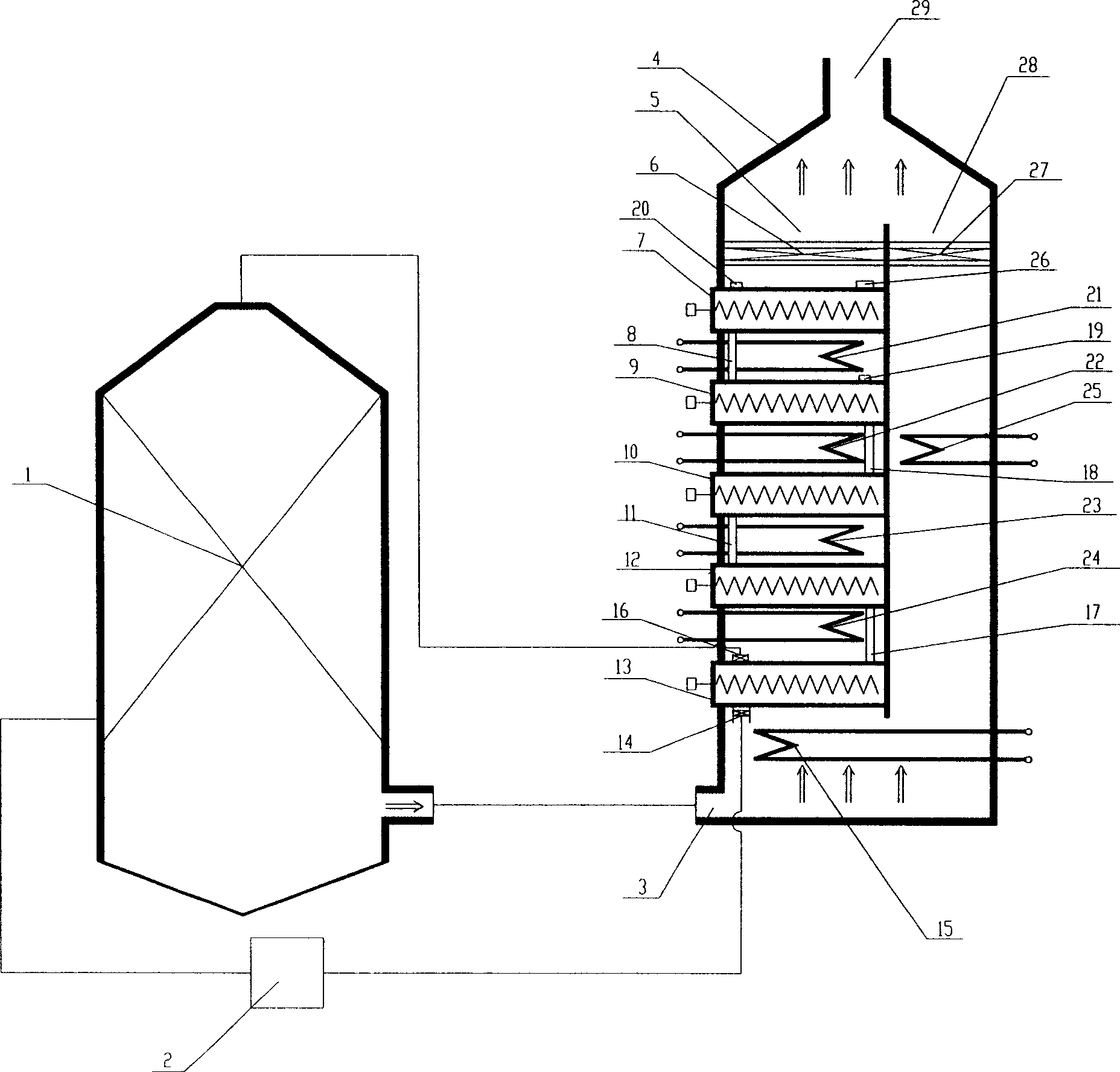

[0030] The biomass graded temperature controlled slow pyrolysis process and its system of the present invention will be further described in detail in conjunction with the accompanying drawings and specific examples:

[0031] The biomass graded temperature-controlled slow pyrolysis system shown in the figure has a vertically arranged system shell 4, and the bottom of the system shell 4 is designed with an external heat source inlet 3, which is directly gasified with biomass The high temperature synthesis gas output end of furnace 1 is connected. The top of the system shell 4 is designed with an outlet 29 of an external hot gas source, through which the high-temperature syngas cooled by heat exchange is sent to the follow-up processing equipment. A main heat exchanger 15 is installed at the bottom of the system shell 4 at the inlet 3 of the external hot gas source, and the main heat exchanger 15 first performs heat exchange and cooling of the incoming high-temperature synthesis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com