Method for extracting linseed oil by water-enzyme process

A technology of linseed oil and linseed, applied in the direction of fat oil/fat production, fat production, fermentation, etc., to achieve the effects of mild operating conditions, improved safety and economy, and no organic solvent residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

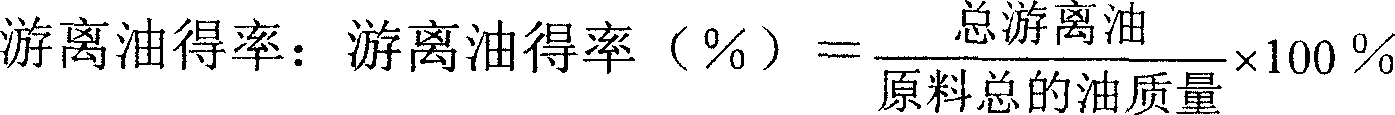

Embodiment 1

[0030] The degummed linseed is dry crushed with a portable traditional Chinese medicine grinder, the crushed linseed and water are mixed at a ratio of 1:5, the pH is adjusted to 9.0, the temperature is 60 ° C, and 1.5% of the raw material mass is added to the alkaline Protease, after enzymatic hydrolysis for 5 hours, adjust the pH to 5.0, lower the temperature to 50°C, add compound cellulase with 1.5% raw material mass, and then enzymatically hydrolyze for 5 hours, obtain free oil after centrifugation, and centrifuge the obtained emulsion again to obtain Total free oil, calculated free oil yield, can reach 82.26%.

Embodiment 2

[0032] The degummed flaxseeds are dry crushed with a portable traditional Chinese medicine grinder, the crushed flaxseeds and water are mixed in a ratio of 1:5, the pH is adjusted to 9.0, the temperature is 60°C, and 1.0% of the raw material mass is added to the alkaline Protease, after enzymatic hydrolysis for 3 hours, adjust the pH to 5.0, lower the temperature to 50°C, add compound cellulase with 1.0% raw material mass, and then enzymolyze for 3 hours, centrifuge to obtain free oil, and centrifuge the obtained emulsion again to obtain Total free oil, calculated free oil yield, can reach 74.42%.

Embodiment 3

[0034] The degummed linseed is dry crushed with a portable traditional Chinese medicine grinder, the crushed linseed and water are mixed in a ratio of 1:4, the pH is adjusted to 9.0, the temperature is 60 ° C, and 1.0% of the mass of the raw material is added. Protease, after enzymatic hydrolysis for 5 hours, adjust the pH to 5.0, lower the temperature to 50°C, add compound cellulase with 1.5% raw material mass, and then enzymolyze for 3 hours, centrifuge to obtain free oil, and centrifuge the obtained emulsion again to obtain Total free oil, calculated free oil yield, can reach 80.20%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com