Blastfurnace slag combined treating system

A technology for processing system and blast furnace slag, which is applied in the field of metallurgical ironmaking equipment, can solve the problems of increasing the wear and tear of circulating water system pipes and equipment, increasing the concentration of suspended particles of water slag in circulating water, and easy wear and tear of slag pumps or air lifters, etc. Achieve the effect of simple equipment and facilities, convenient operation and maintenance, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

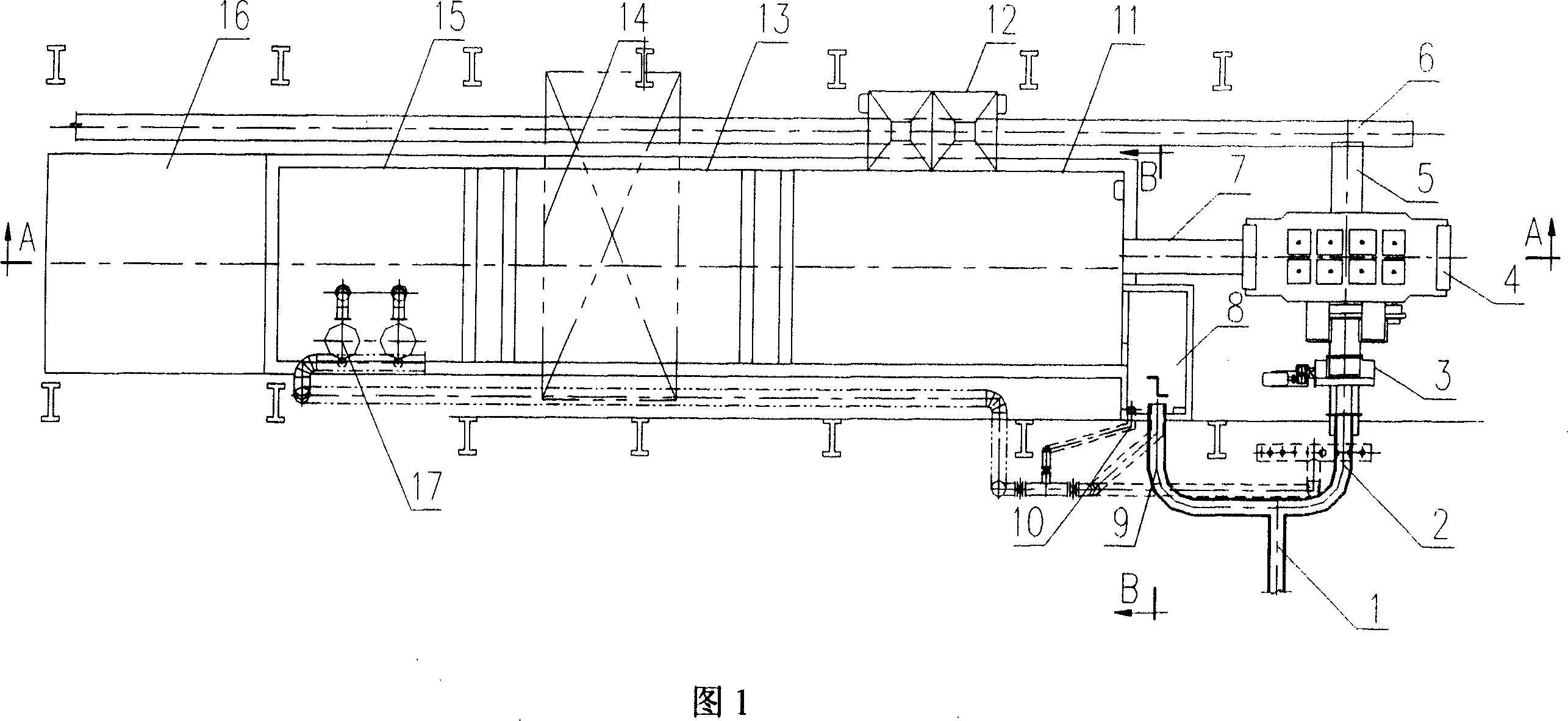

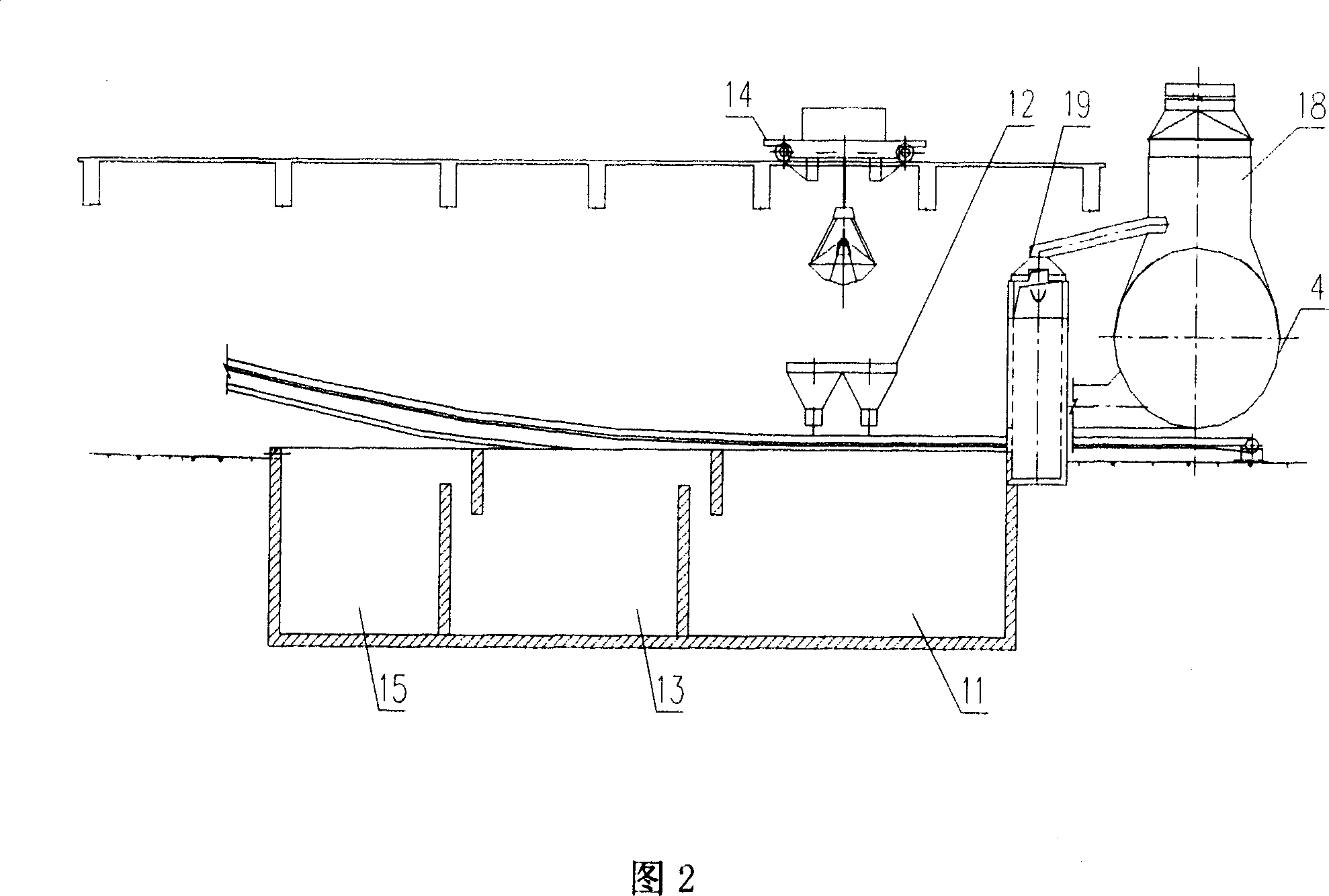

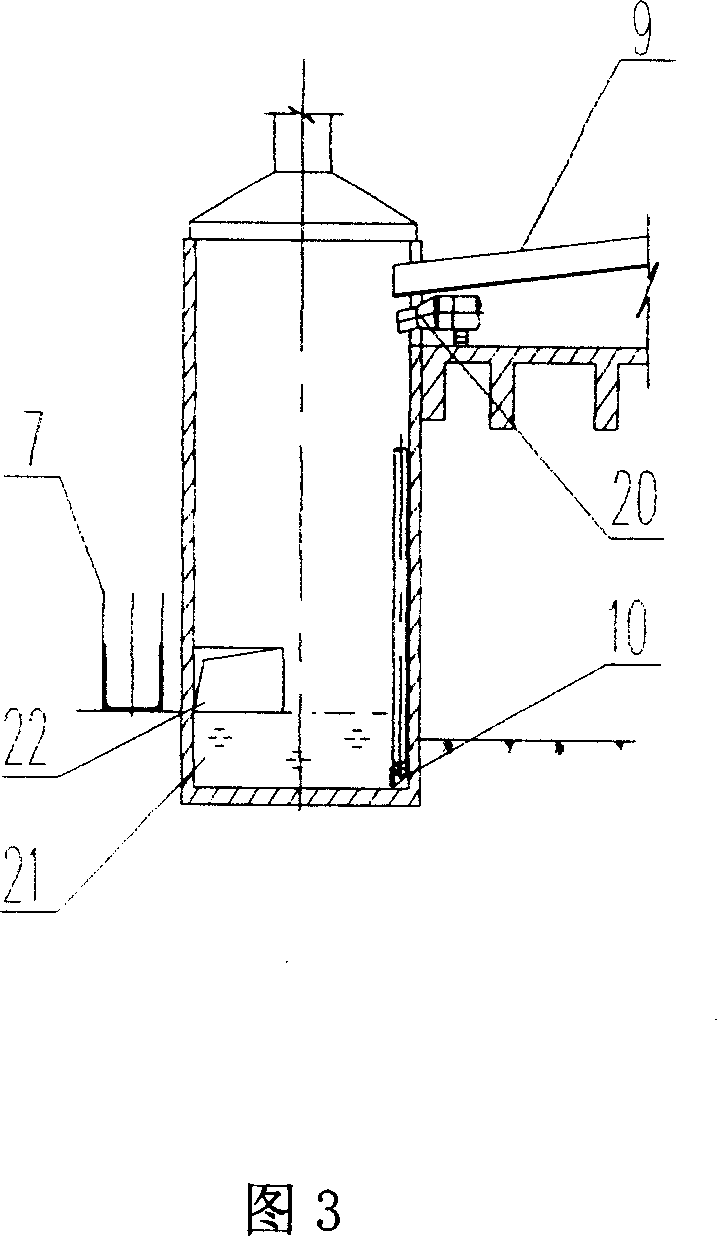

[0018] The blast furnace slag combined treatment system shown in Figure 1 includes slag ditch 1, slag branch ditch 1, round slag treatment device, slag branch ditch 2 9, slag flushing tank 8, and advection slag treatment device ; Among them, the wheel method water slag treatment device is composed of a granulator 3, a dehydration device 4, a lower hopper 5, a belt conveyor 6, and so on. The slag branch ditch 2 is connected with the granulator 3, and the granulator 3 is connected with the dehydration device 4. The dewatering device 4 is provided with a backwater ditch 7 and connected to a sedimentation tank 11. One end of the lower hopper 5 extends into the dewatering device 4, and the other end of the lower hopper 5 is connected to the belt conveyor 6; the advection method water slag treatment device has a sedimentation tank 1. 11. The second slag tank 13, the circulating water tank 15, the circulating water pump 17, the second slag branch trench 9 is connected with the slag flush...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com