Digital low power consumption high-precision high voltage generator

A high-voltage generator, low-power technology, used in X-ray equipment, electrical components, etc., can solve the problems of high price, high power, and few high-voltage generators, and achieve improved stability, high reliability, and light weight. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

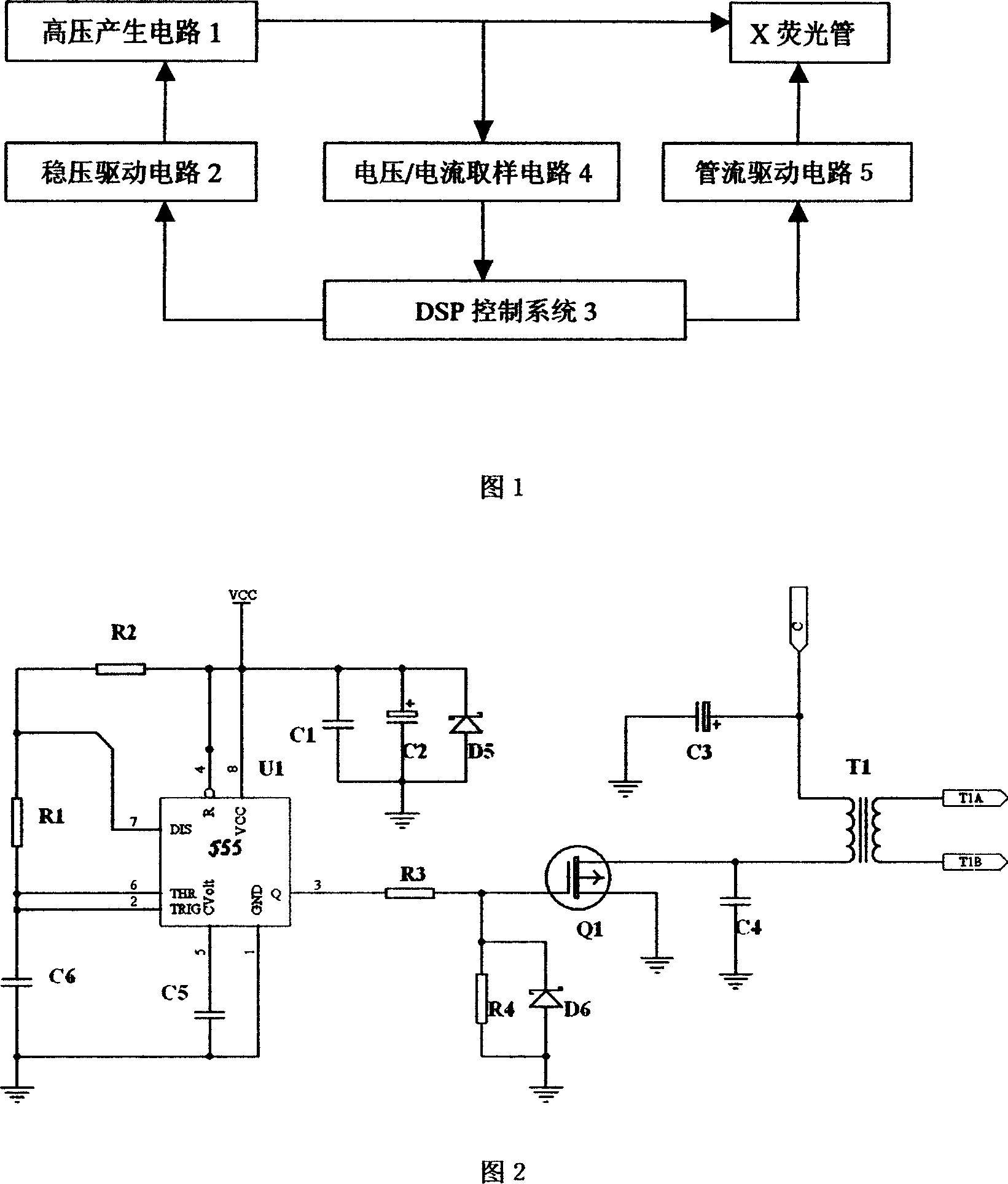

[0021] 1. High voltage generating circuit 1

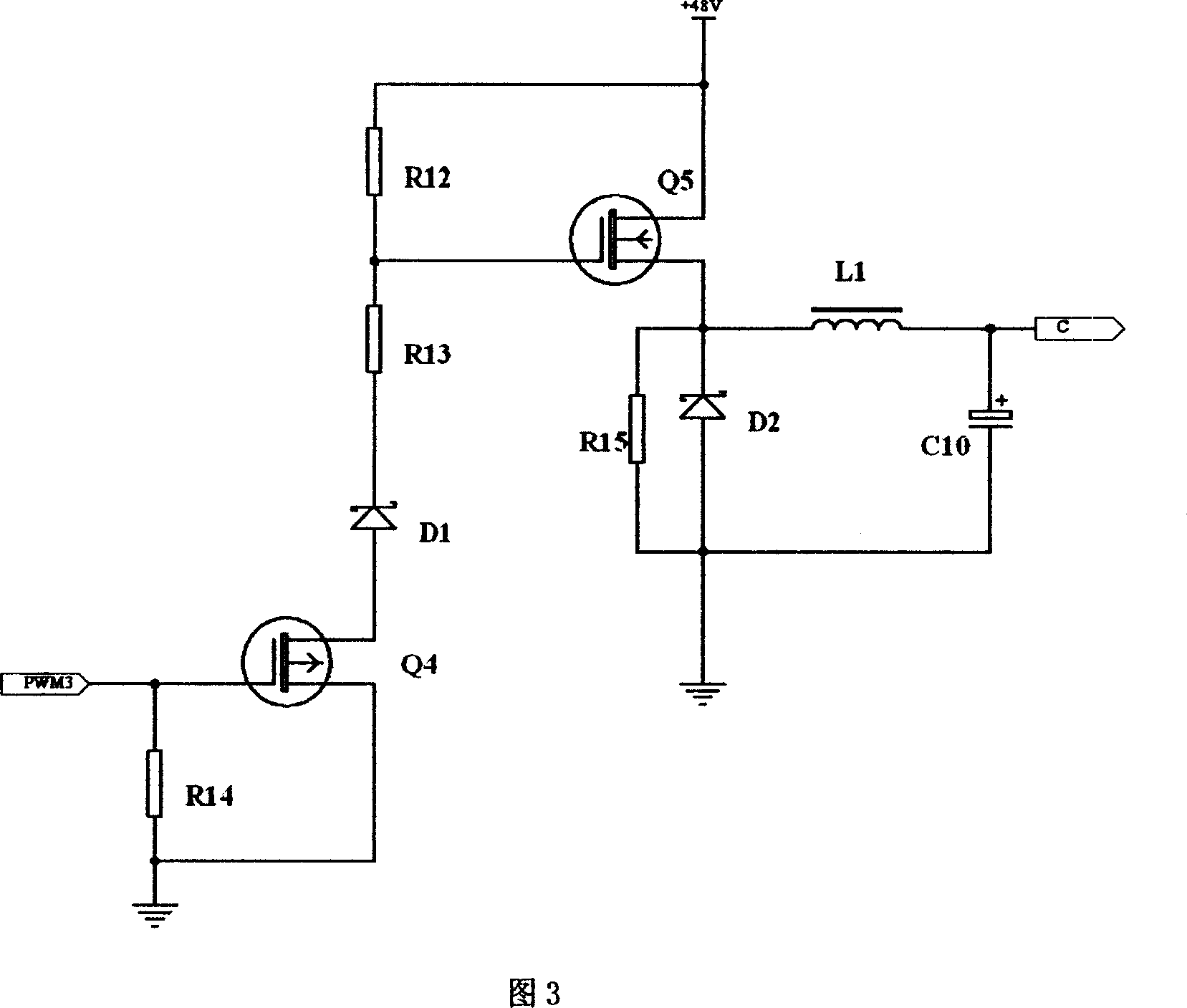

[0022] The high-voltage generating circuit is shown in Figure 2, which is composed of a multivibrator, a field effect transistor (FET) Q1 and a flyback transformer (FBT) T1. The multivibrator composed of 555 timer U1 and R1, R2, C5, C6 outputs a rectangular pulse with a frequency of 18KHz (the duty cycle is about 50%) to drive Q1 to be turned on and off. When Q1 is turned on, the input voltage is applied to the primary winding of T1, and a voltage is induced in the secondary winding. When Q1 is cut off, the magnetic field energy stored in the primary winding will be released at the moment of disconnection and generate a high counter electromotive force, that is, the reverse voltage V1, and the voltage value can be obtained by the formula V 1 = - L di dt calculation. where L is the inductance of the core, is the rate of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com