Material of negative electrode for lithium secondary battery, negative electrode utilizing the material, lithium secondary battery utilizing the negative electrode, and process for producing the mater

A technology of lithium secondary battery and negative electrode material, applied in the direction of secondary battery, battery electrode, lithium storage battery, etc., can solve the problem of unrealistic, large amount of lithium metal, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0060] Hereinafter, the effects of the present invention will be described using specific examples. First, Embodiment 1 of the present invention using the prismatic battery shown in FIG. 3 will be described. First, the production of sample LE1 will be described.

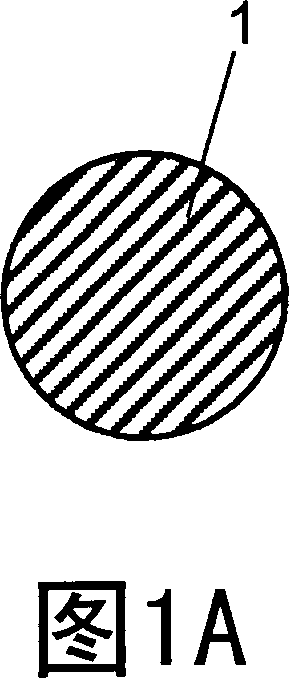

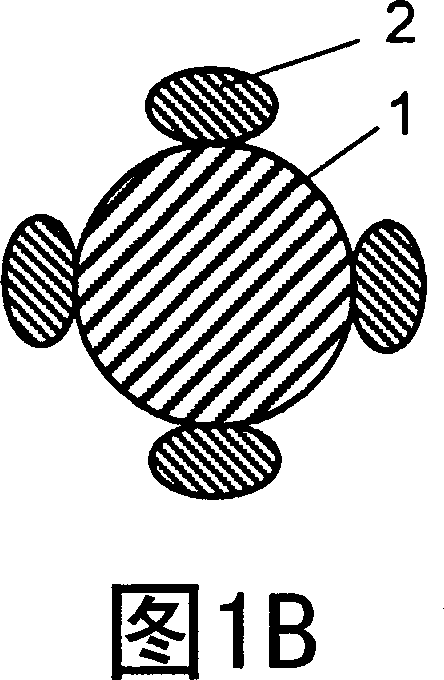

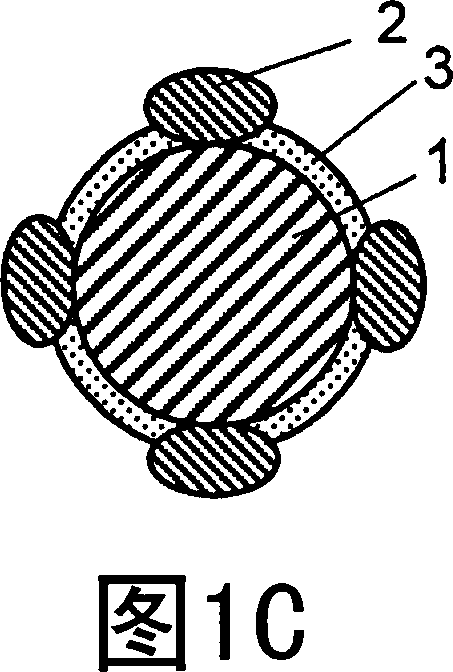

[0061] The negative electrode material was synthesized as follows. The silicon powder was mixed with the titanium powder so that the molar ratio of the elements was 94.4:5.6. 1.2 kg of the mixed powder and 300 kg of stainless steel balls with a diameter of 1 inch were put into a vibratory ball mill device. Thereafter, the inside of the apparatus was replaced with argon gas, and pulverization treatment was performed for 60 hours at an amplitude of 8 mm and a vibration frequency of 1200 rpm. In this way, base material particles 1 composed of Si—Ti (phase B) and Si (phase A) were obtained. When the base material particle 1 was observed by TEM, it was confirmed that crystallites of 50 nm or less accounted for 80% or ...

Embodiment approach 2

[0083] In Embodiment 2 of the present invention, the structure of the coin type battery shown in FIG. 4 and the result of examination will be described. First, the manufacturing process of sample CE1 is demonstrated.

[0084] The negative electrode 7A was fabricated as follows. The negative electrode material obtained by the same method as sample LE4 of Embodiment 1, AB as a conductive agent, and PAA as a binder were mixed at a weight ratio of solid components of 82:20:10 to prepare an electrode mixture. This electrode mixture was shaped into pellets with a diameter of 4 mm and a thickness of 0.3 mm, and dried at 200° C. for 12 hours. In this way, negative electrode 7A was obtained. In order to maintain the slowly oxidized state of the base material particles 1, the above-mentioned negative electrode 7A was produced in an argon atmosphere.

[0085] Next, the manufacturing process of the positive electrode 5A will be described. Manganese dioxide and lithium hydroxide were ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com