Full solid thin film lithium battery and its producing method

A lithium battery, all-solid-state technology, applied in the manufacture of secondary batteries, batteries with solid electrolytes, battery electrodes, etc., can solve the problems of low manufacturing cost, performance, physical state, cycle life, and high rate charge and discharge of thin film lithium batteries Poor performance and other problems, to achieve the effect of improving air resistance, increasing electrochemical reaction performance and efficiency, and high discharge voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

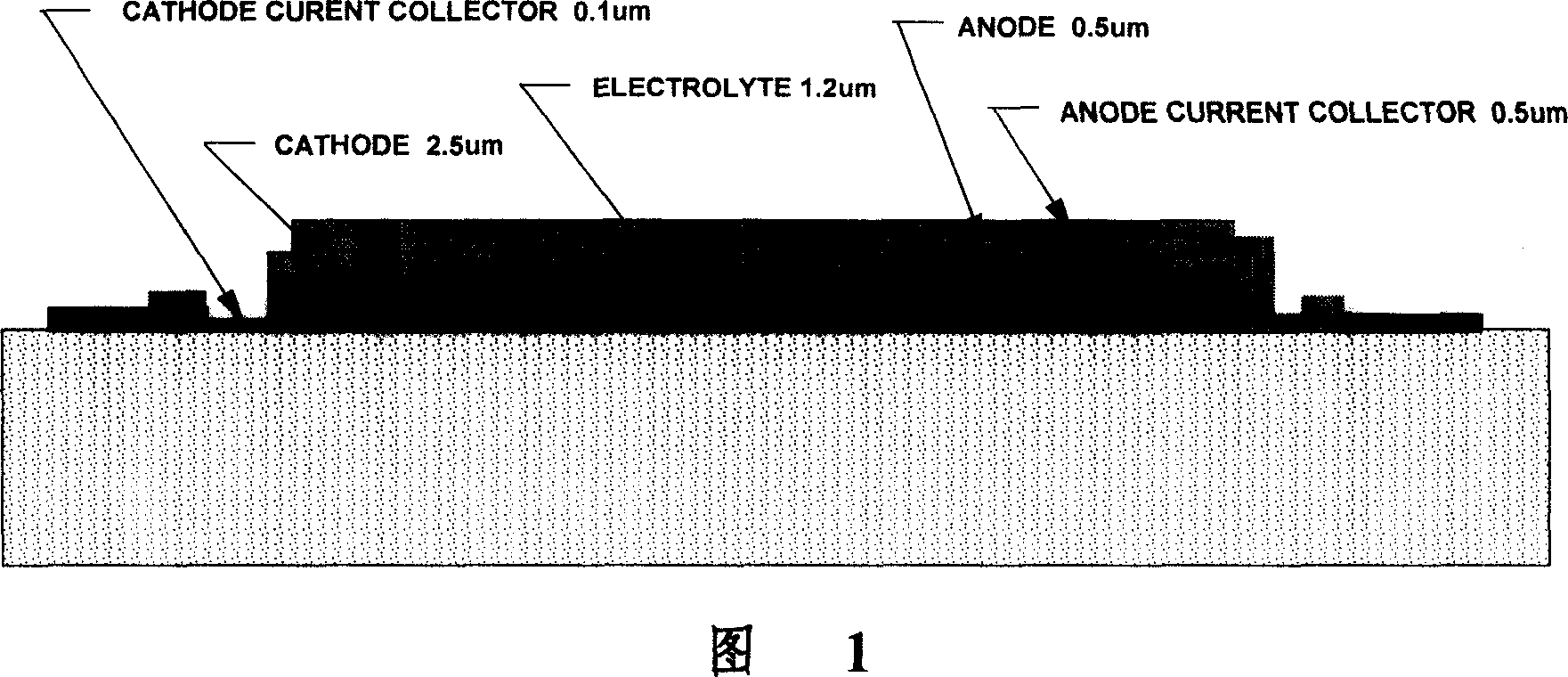

[0092] see picture 1. The all-solid-state thin-film lithium battery is composed of a positive electrode film, a solid electrolyte film located between the positive electrode film and the negative electrode film, a current collector film connected to the positive and negative electrodes, and a packaging material film for sealed packaging. The positive electrode material is LiCoO 2 , the negative electrode material is SnN x , the solid electrolyte is LiPON, the current collector film connected to the positive and negative electrodes is a gold thin layer, and the composite multilayer film of metal / polymer material as the packaging material is an aluminum / polyethylene multilayer composite or aluminum / polypropylene multilayer composite.

[0093] First, the substrate is cleaned. The polymer material substrate (12-75 microns) is cleaned with 1M HCl, then washed with distilled water for 3 times, and dried. Then, direct current sputtering is used to fabricate the positive electrode ...

Embodiment 2

[0099] Except the following differences, others are as in Example 1.

[0100] The negative electrode material is metal lithium, and the substrate is made of ceramics.

[0101] The ceramic material substrate was cleaned with 1M HCl, then washed with distilled water for 5 times, and dried. Then, direct current sputtering is used to make the positive electrode current collector and the gold target, and the thickness of the positive electrode current collector is about 0.3-0.5 microns.

[0102] Next, at 10 -3 -10 -5 Under a vacuum of Pa, in an oxygen atmosphere, LiCoO 2 As the target, the positive electrode is deposited by radio frequency magnetron sputtering, the magnetron sputtering power is 200-300W, the magnetron sputtering rate is 0.8-2 microns / hour, the flow rate is 20-30sccm, and the thickness of the metal oxide film deposited by sputtering at 2-5 microns.

[0103] Then, in a nitrogen atmosphere, the LiPON inorganic electrolyte was sputtered by RF sputtering Li 3 PO ...

Embodiment 3

[0108] Except the following differences, others are as in Example 1.

[0109] The cathode material is LiMn 2 o 4 , the negative electrode material is metallic lithium, and the substrate is made of ceramics.

[0110] The ceramic material substrate was cleaned with 1M HCl, then washed with distilled water for 5 times, and dried. Then, direct current sputtering is used to make the positive electrode current collector and the gold target, and the thickness of the positive electrode current collector is about 0.3-0.5 microns.

[0111] Next, at 10 -3 -10 -5 Under a vacuum of Pa, in an oxygen atmosphere, LiMn 2 o 4 As the target, the positive electrode is deposited by radio frequency magnetron sputtering, the magnetron sputtering power is 300-400W, the magnetron sputtering rate is 0.8-2 microns / hour, the flow rate is 30-40sccm, and the LiMn deposited by sputtering 2 o 4 The thickness of the film is 2-5 microns.

[0112] Then, in a nitrogen atmosphere, the LiPON inorganic ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com