Cement mixing agent

A mixture and cement technology, applied in the field of cement mixture, can solve problems such as insufficient water reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

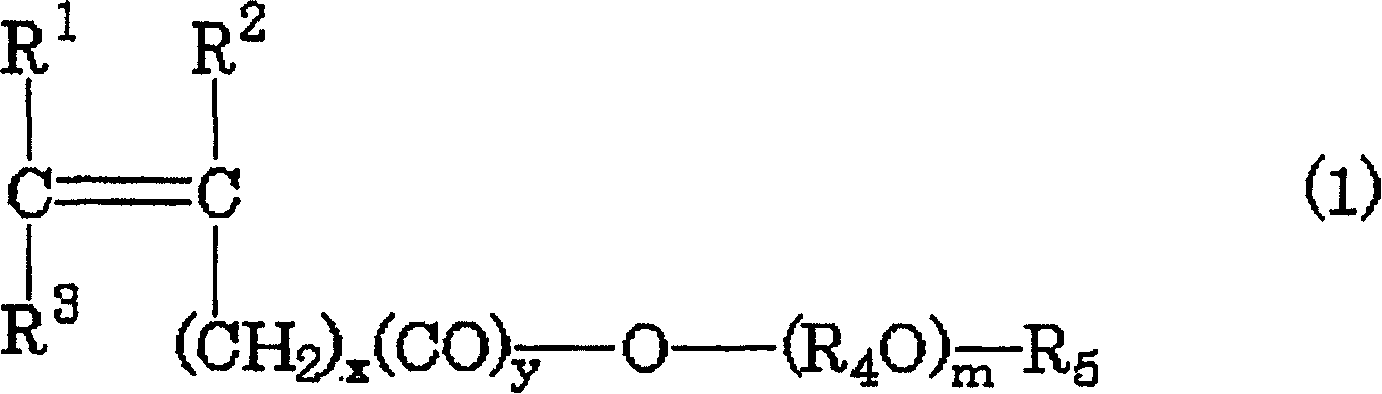

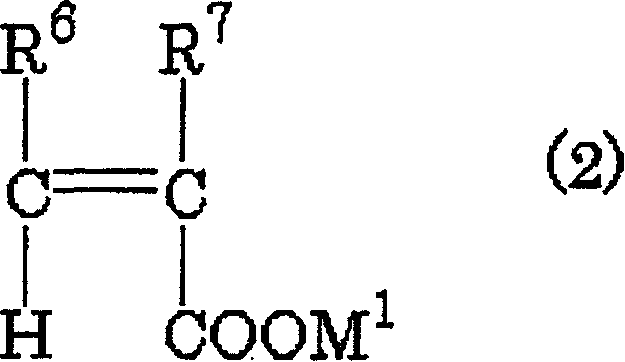

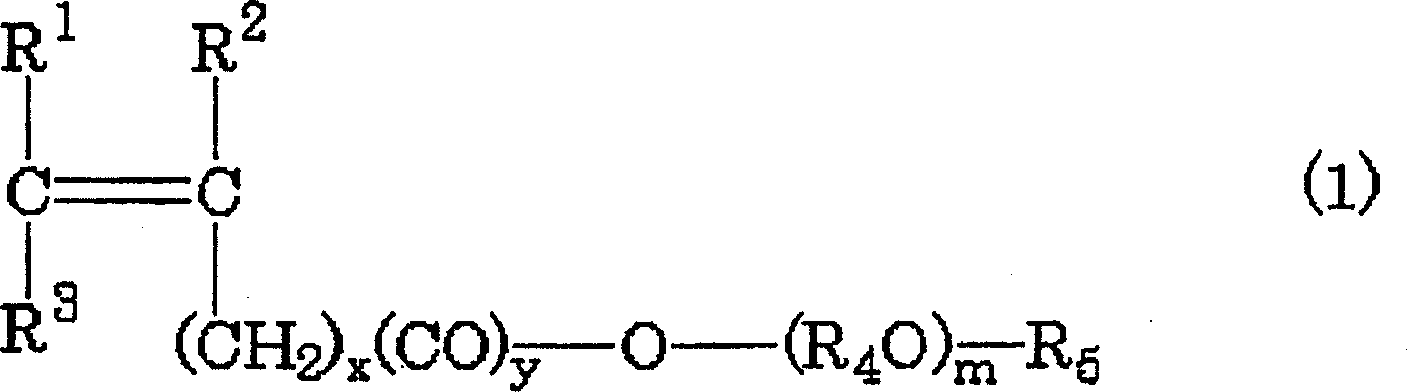

Method used

Image

Examples

manufacture example

[0228] Add 614 g of commercially available polyethyleneimine (polyechinimine) (number-average molecular weight is 600; ethyleneimine addition number is 14) and 4 g of sodium hydride in a pressure vessel equipped with a stirrer, a pressure gauge, and a thermometer, and stir While sufficiently replacing with nitrogen, the temperature was raised to 150°C. Next, while slowly adding 1886 g (the average addition number of active hydrogen to polyethyleneimine is 3 moles) of ethylene oxide was reacted, and after adding all of it, it was aged at the same temperature for 30 minutes to obtain 2500 g of polyethyleneimine. Alkyl imine oxide alkylene compounds. This compound is designated as intermediate (a).

[0229] Production example of intermediate (b)

[0230] 474 g of the intermediate (a) was added to a pressure vessel equipped with a stirrer, a pressure gauge, and a thermometer, and the mixture was fully replaced with nitrogen while stirring, and then the temperature was raised to ...

manufacture example 2

[0233] In the pressure vessel that is equipped with stirrer, pressure gauge, thermometer, add 2334g of manufacturing example 1 to obtain , was fully replaced with nitrogen while stirring, and then the temperature was raised to 130°C. Next, while slowly adding 166 g (the average addition number of active hydrogen to polyethyleneimine is 6 moles) of propylene oxide was reacted, and after adding all of it, it was aged at the same temperature for 5 hours to obtain 2500 g of polyethyleneimine. Alkyl imine oxide alkylene compounds. Set the compound to .

manufacture example 3~7、30~36

[0235] Except for the average added moles of ethyleneimine and alkylene oxide, etc., as described in Table 1, the polyalkyleneimine oxide alkylene as shown in Table 1 was obtained in the same manner as in Production Example 1 or Production Example 2. adducts. In the table, EIn represents the average addition number of ethyleneimine, en1 and en2 represent the average addition number of ethylene oxide to the active hydrogen of polyethyleneimine, and pn represents the average addition number of propylene oxide to the active hydrogen of polyethyleneimine. Average additions. In addition, the molecular weight of polyethyleneimine used the molecular weight equivalent to EIn described in Table 1, respectively. The mass % of PO in the table shows the mass % of propylene oxide in 100 mass % of alkylene oxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com