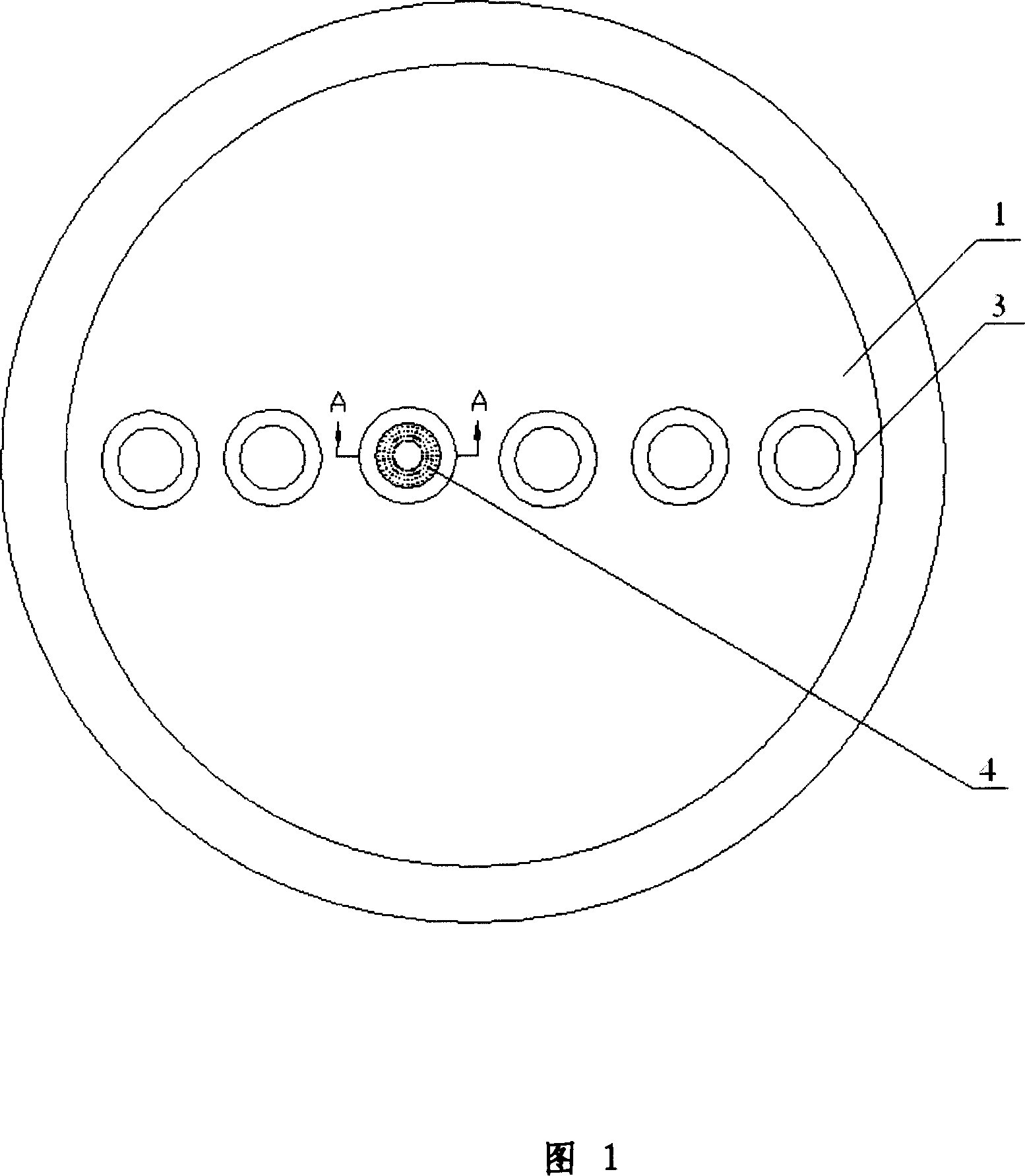

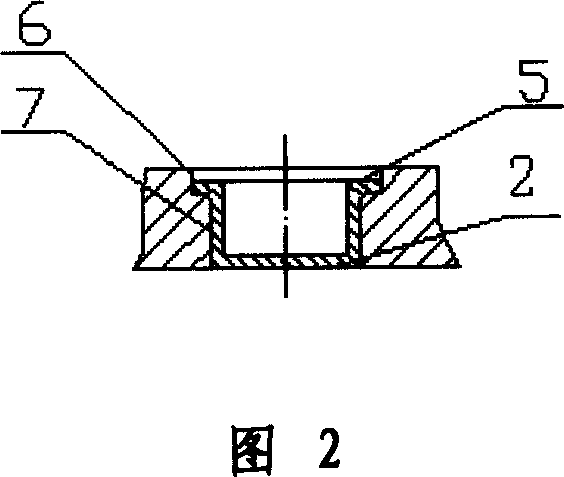

Composite spinneret plate for solvent method cellulose fiber production

A technology of cellulose fiber and composite spinning, which is applied in the direction of spinneret assemblies, textiles and papermaking, etc. It can solve the problems of complex structure, easy to cause eddy current, and difficult operation of the annular cooling device, and achieve simple structure and high spinning efficiency. The effect of speed and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The pulp with a degree of polymerization (DP) of 600 is dissolved in NMMO aqueous solution, the cellulose content is 10%, the refractive index of the prepared cellulose spinning solution is 1.4860, the viscosity is 1000 Pa·s, and it is light brown and transparent. After being pressurized by the booster pump, it is filtered by the pre-filter and then enters the melt-spinning box.

[0036] The composite spinneret is inlaid with 6 spinneret caps, and each spinneret has 400 spinneret holes with a diameter of Φ=0.07mm. The total number of holes in the composite spinneret is 2400. During spinning, the temperature of the spinning liquid is 90°C, and the side blowing with a wind speed of 4m / min is used for cooling, 10% NMMO aqueous solution is used as a coagulant, the temperature of the coagulation bath is 20°C, and the winding speed is 120m / min. After washing, crimping, cutting, spraying, and drying, the strips obtained high-quality cellulose fibers with a fineness of 1.47 dte...

Embodiment 2

[0038]The pulp with a degree of polymerization (DP) of 700 was dissolved in an NMMO aqueous solution with a cellulose content of 9%. The resulting cellulose spinning solution had a refractive index of 1.4850 and a viscosity of 1200 Pa·s, which was light brown and transparent. After being pressurized by the booster pump, it is filtered by the pre-filter and then enters the melt-spinning box.

[0039] The composite spinneret is inlaid with 6 spinneret caps, and each spinneret has 600 spinneret holes with a diameter of Φ=0.07mm. The total number of holes in the composite spinneret is 3600. During spinning, the temperature of the spinning solution is 92°C, the wind speed is 4.5m / min for cooling, the 10% NMMO aqueous solution is used as the coagulant, the temperature of the coagulation bath is 20°C, and the winding speed is 130m / min. After the filaments are washed, crimped, cut, sprayed, and dried, a high-quality cellulose fiber with a fineness of 1.30 dtex, a single fiber dry stre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com