Temp. data collecting and controlling system of engineering mechanical hydraulic motor radiating system

A technology of hydraulic motor and heat dissipation system, which is applied in the direction of electric speed/acceleration control, electric temperature control, speed/acceleration control, etc., which can solve problems such as system overheating, waste of fuel, and large machine wear, and achieve reduction Noise of the whole machine, improving utilization rate, and solving the effect of large wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

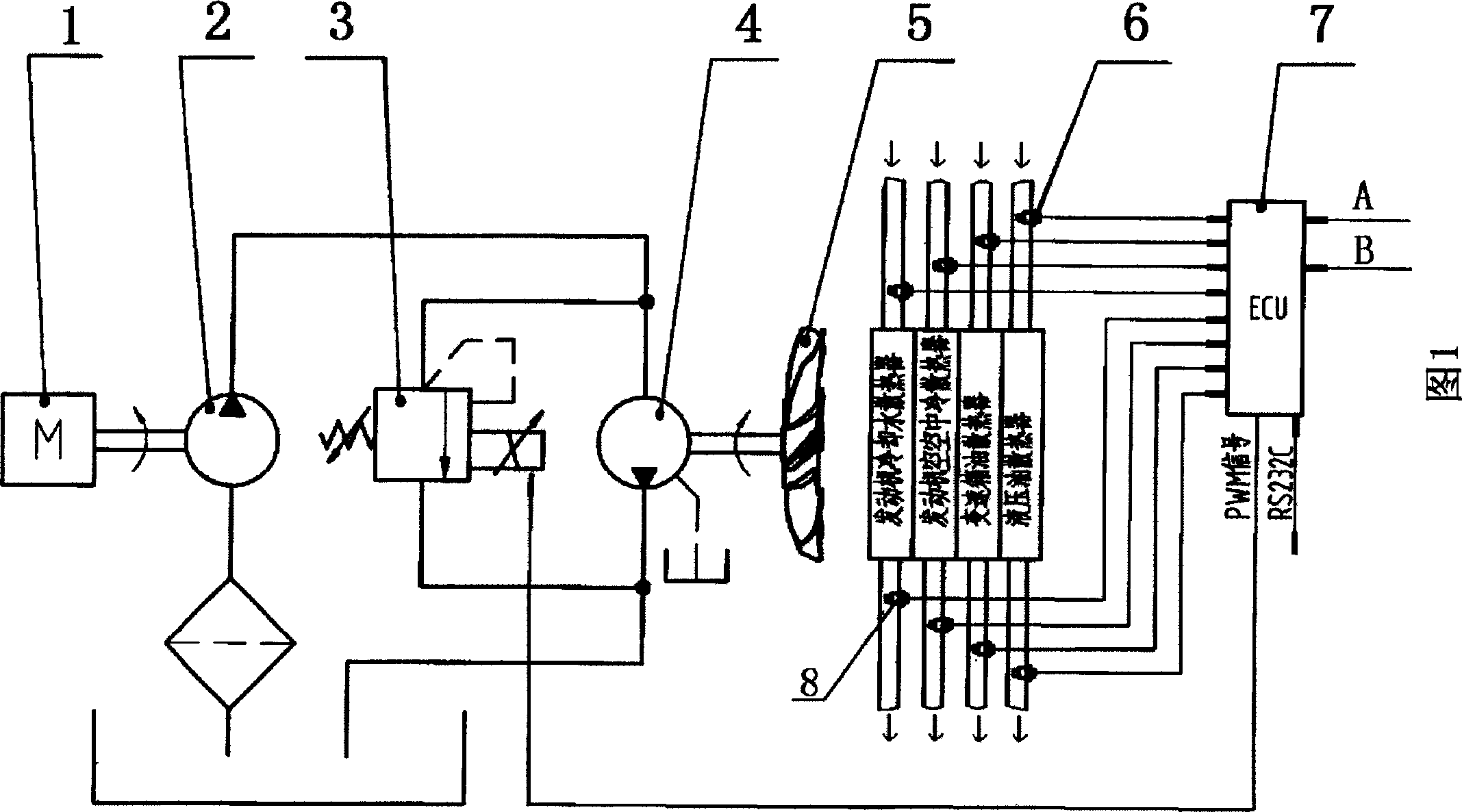

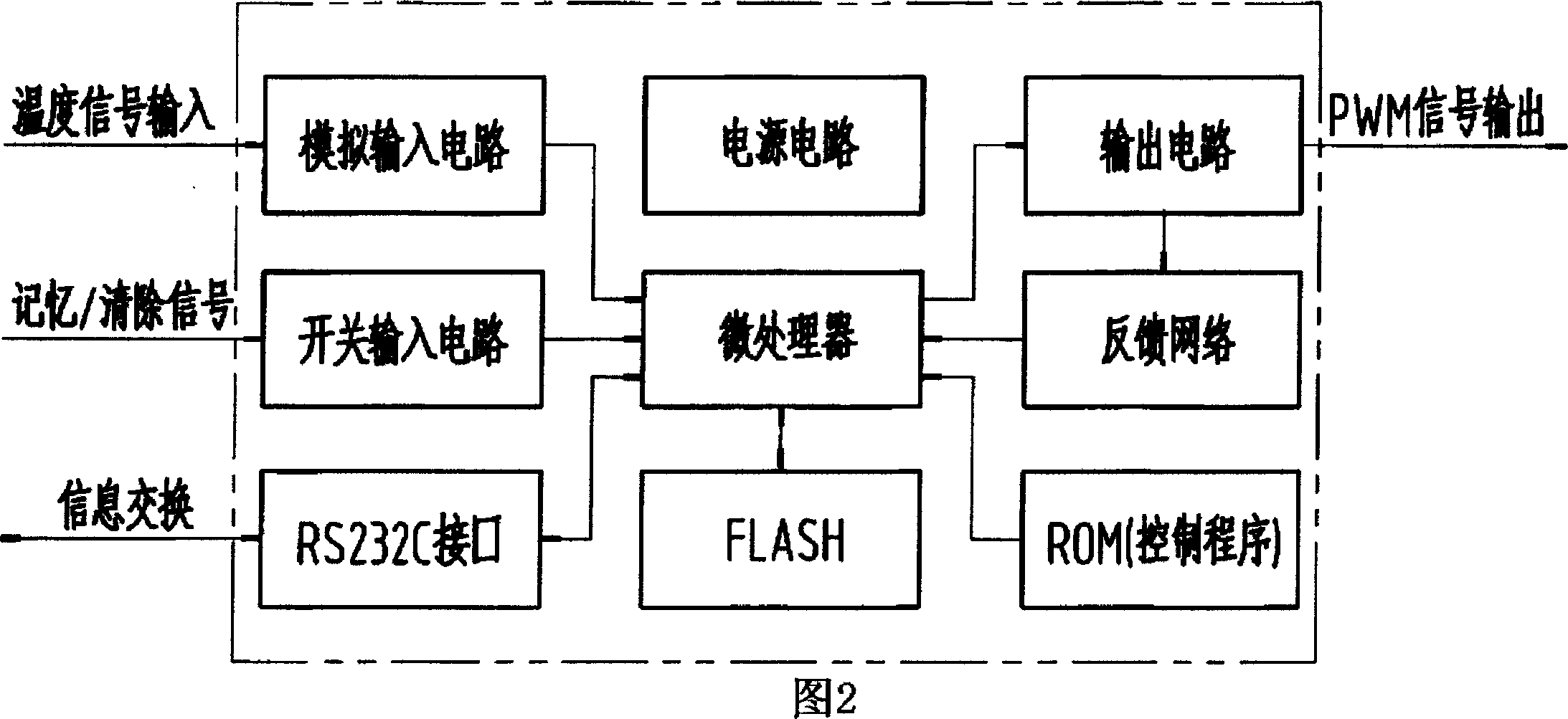

[0013] In the present invention, the quantitative motor 4 drives the fan 5, and a temperature sensor 8 is installed at the outlet of the heat dissipation assembly. The signal transmitted by the temperature sensor 8 controls the proportional electromagnetic pressure reducing valve 3 to realize the adjustment of the fan 5, and is installed at the entrance of the heat dissipation assembly. The temperature sensor 6 collects the inlet and outlet temperatures of the heat dissipation components at the same time; it has an electronic control unit (ECU) to control the collected signals, generate corresponding driving current, and drive the proportional electromagnetic pressure reducing valve.

[0014] The heat dissipation assembly refers to the engine cooling water radiator, and the electronic control unit (ECU) has a control circuit that controls the change data of the inlet temperature of the engine cooling water radiator between its specified lower limit value and upper limit value, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com