Semiconductor device and integrated circuit device

A semiconductor and conductive coating technology, applied in the manufacture of semiconductor devices, circuits, semiconductor/solid-state devices, etc., can solve the problems of limited use of porous dielectric layer materials, weak mechanical hardness, etc., to improve mechanical hardness and reduce signal delayed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

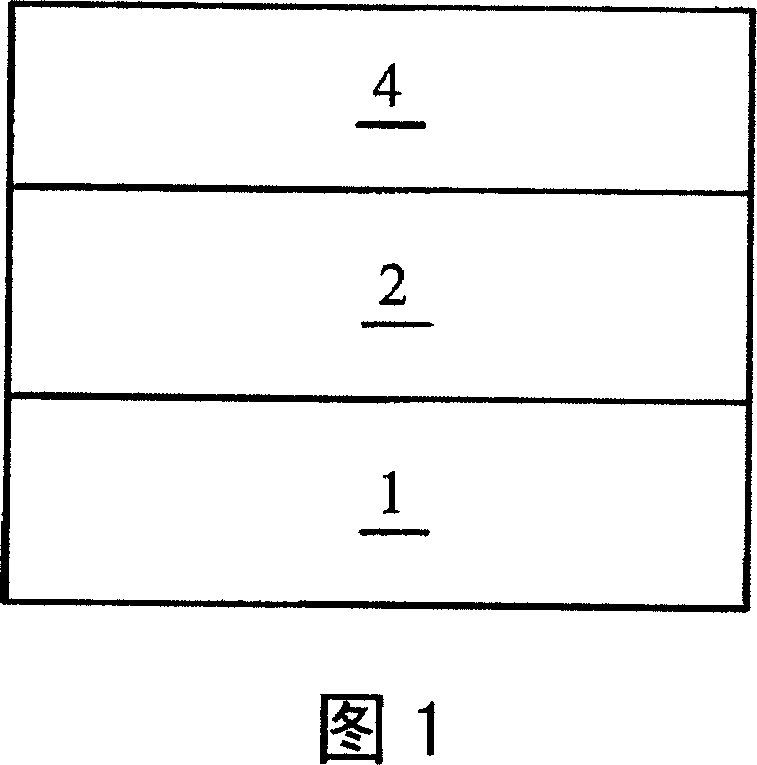

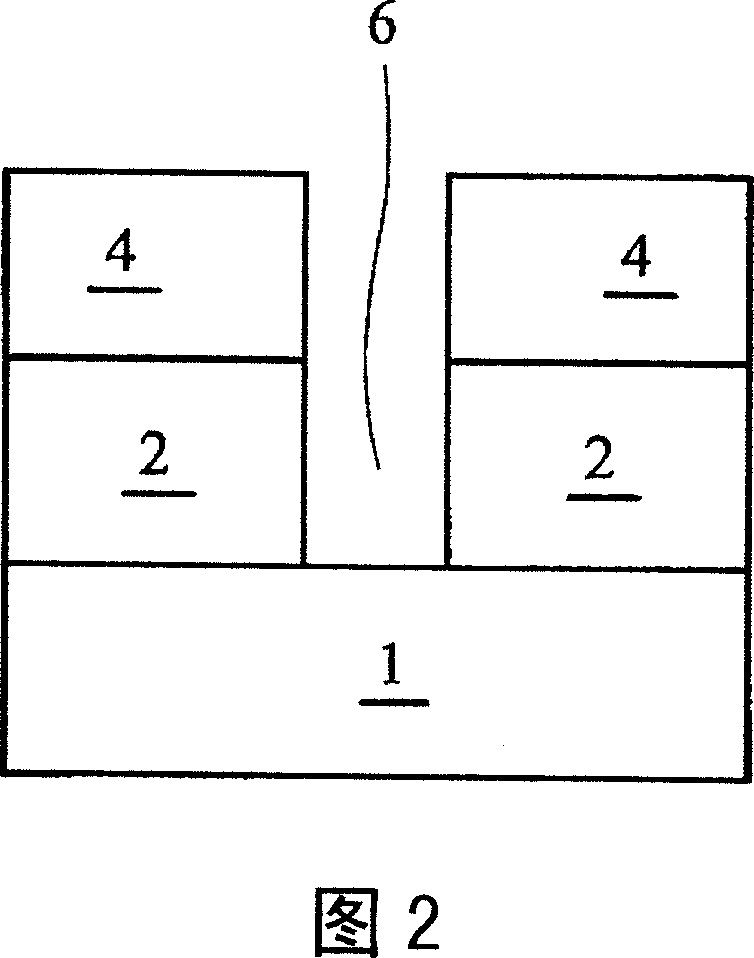

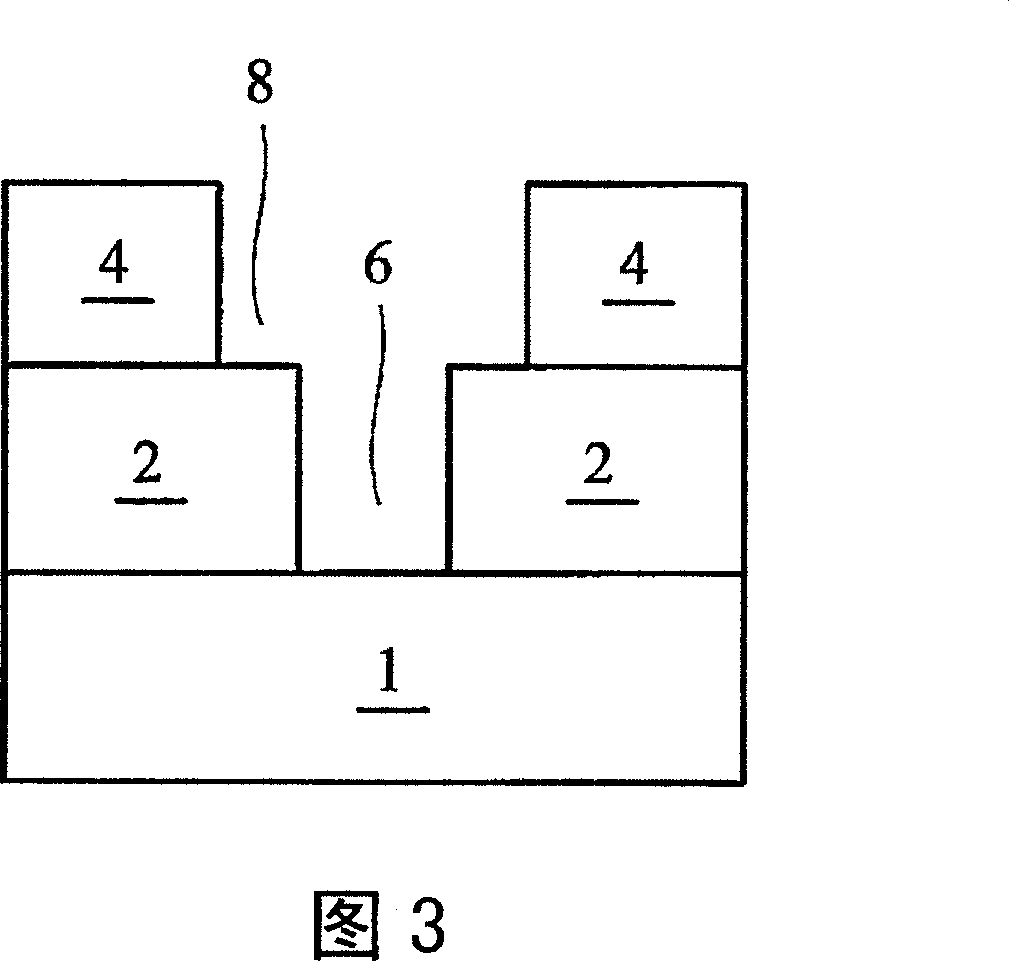

[0034] The preferred embodiment of the present invention integrates ultra-low-k dielectric layers and higher-k dielectric layers in a dual damascene process. FIGS. 1 to 7 and FIGS. 10 to 14 show cross-sectional views of intermediate stages of the process of preferred embodiments. In each embodiment of the present invention, the same symbols represent the same components.

[0035] Please refer to FIG. 1 , which shows the formation of a semiconductor device. Starting from the substrate 1 , a dielectric layer 2 , also referred to as a first dielectric layer 2 , is formed on the substrate 1 . The dielectric constant of the first dielectric layer 2 is preferably less than about 2.7, and the average porosity is greater than about 10%. There are many materials that can be used for the first dielectric layer 2, including but not limited to carbon-doped silicon oxides, fluorine-doped silicon oxides, organic low dielectric constant materials, and porous low dielectric constant material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com