Immersed hollow fiber membrane module

A fiber membrane and immersion technology, applied in the field of external pressure immersion hollow fiber membrane modules, can solve the problems of loss of filtration efficiency, dehydration of membrane bundles, sufficient shaking, etc., and achieve easy transportation and construction installation, high pollution resistance, and prevent accumulation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

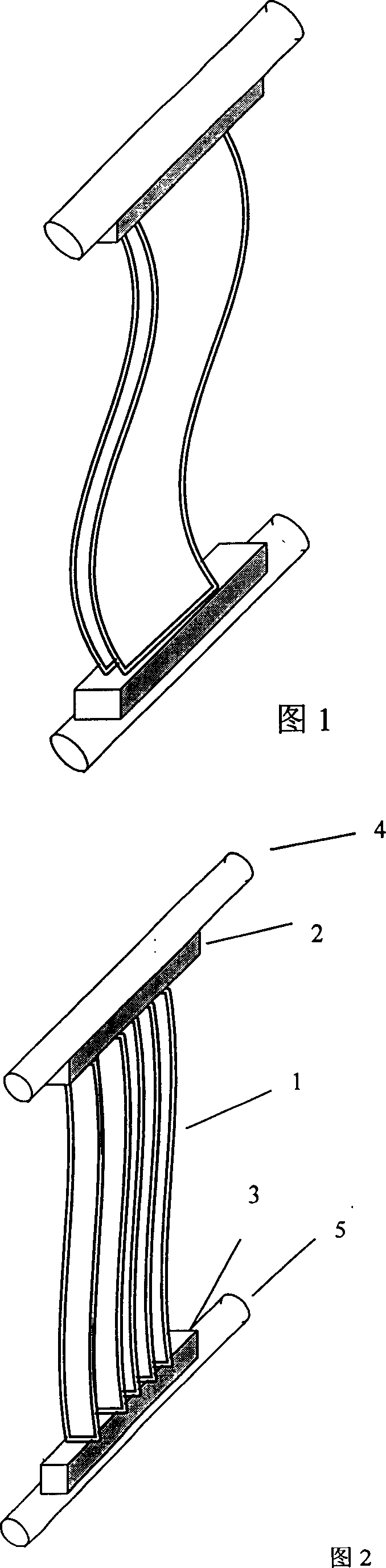

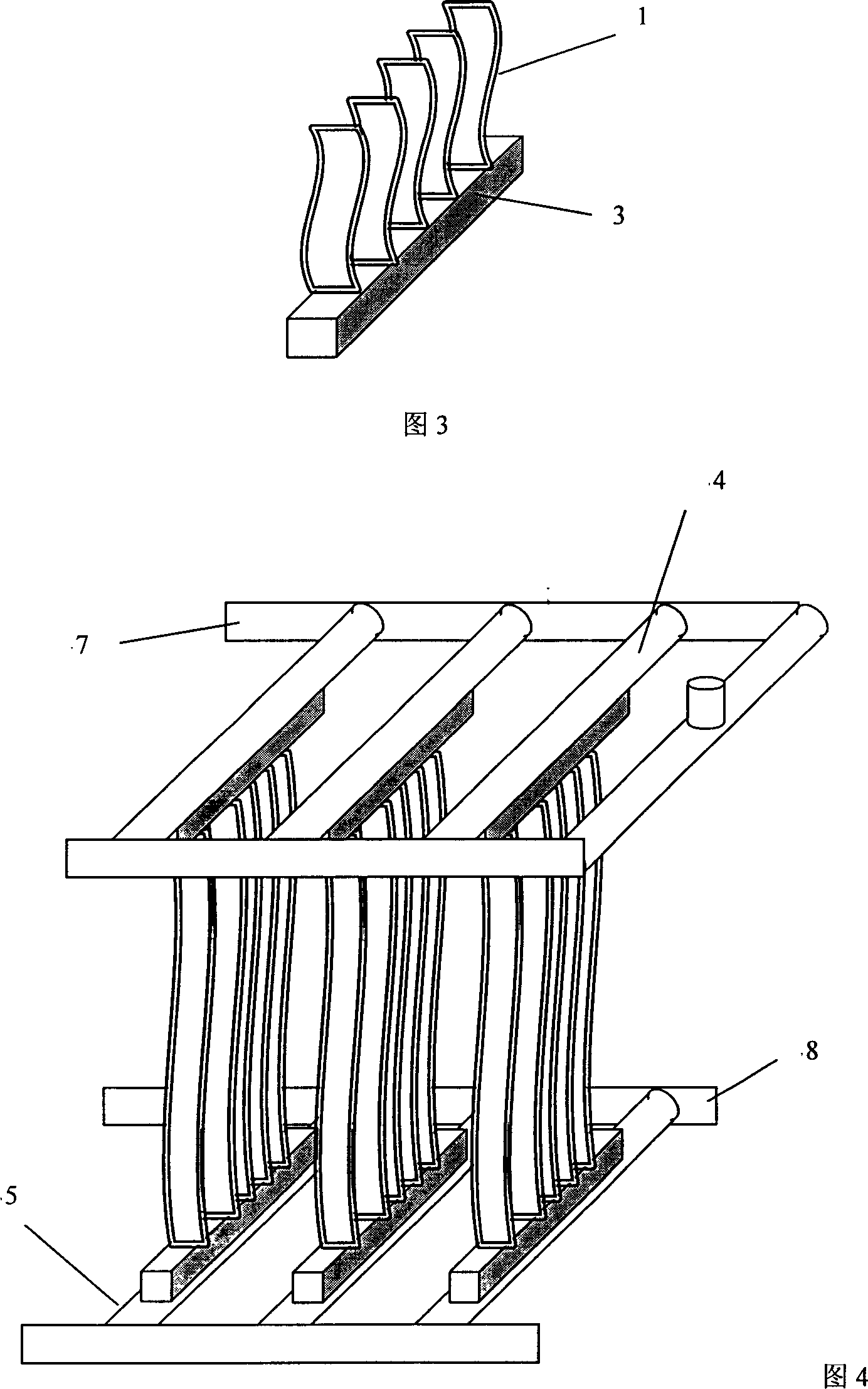

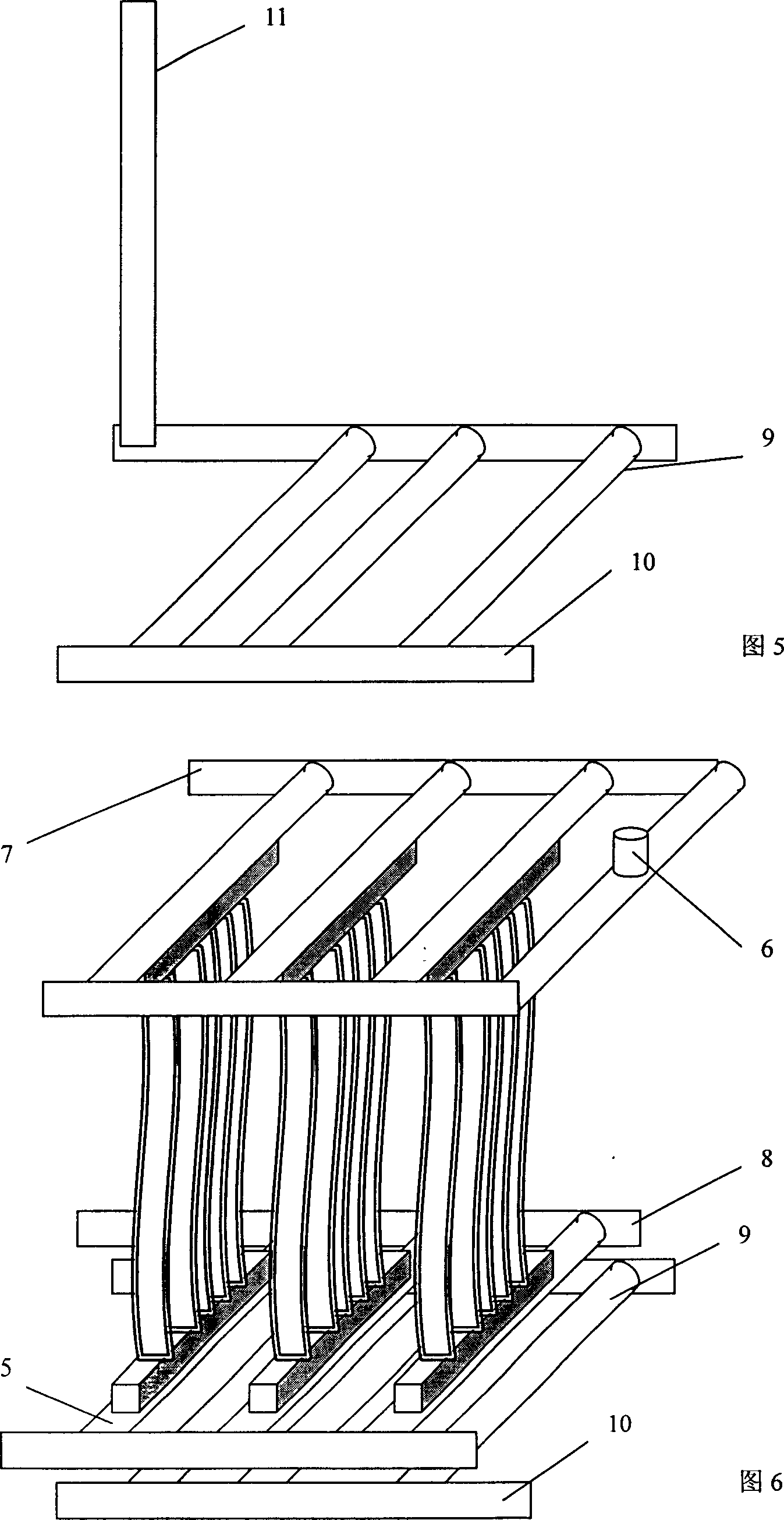

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: wherein the number of membrane filaments of each small piece of hollow fiber membrane is 90, and the hollow fibers are closely arranged in three layers, each layer is about 30, and there are 45 small pieces in total, and the distance between the pieces is 6mm;

Embodiment 2

[0036] Embodiment 2: The number of membrane filaments per sheet is 60, which are closely arranged in two layers, about 30 in each layer, and there are 70 sheets in total, and the distance between the sheets is 4mm;

Embodiment 3

[0037] Embodiment 3: The number of membrane filaments per sheet is 120, which are arranged in four layers, about 30 in each layer, and there are 35 sheets in total, and the distance between the sheets is 8mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com