Aerator of quartz micropores

A technology of microporous aerator and quartz, applied in water aeration, chemical instruments and methods, flotation water/sewage treatment, etc. Aeration effect is not very good and other problems, to achieve good aeration effect, not easy to aging, long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

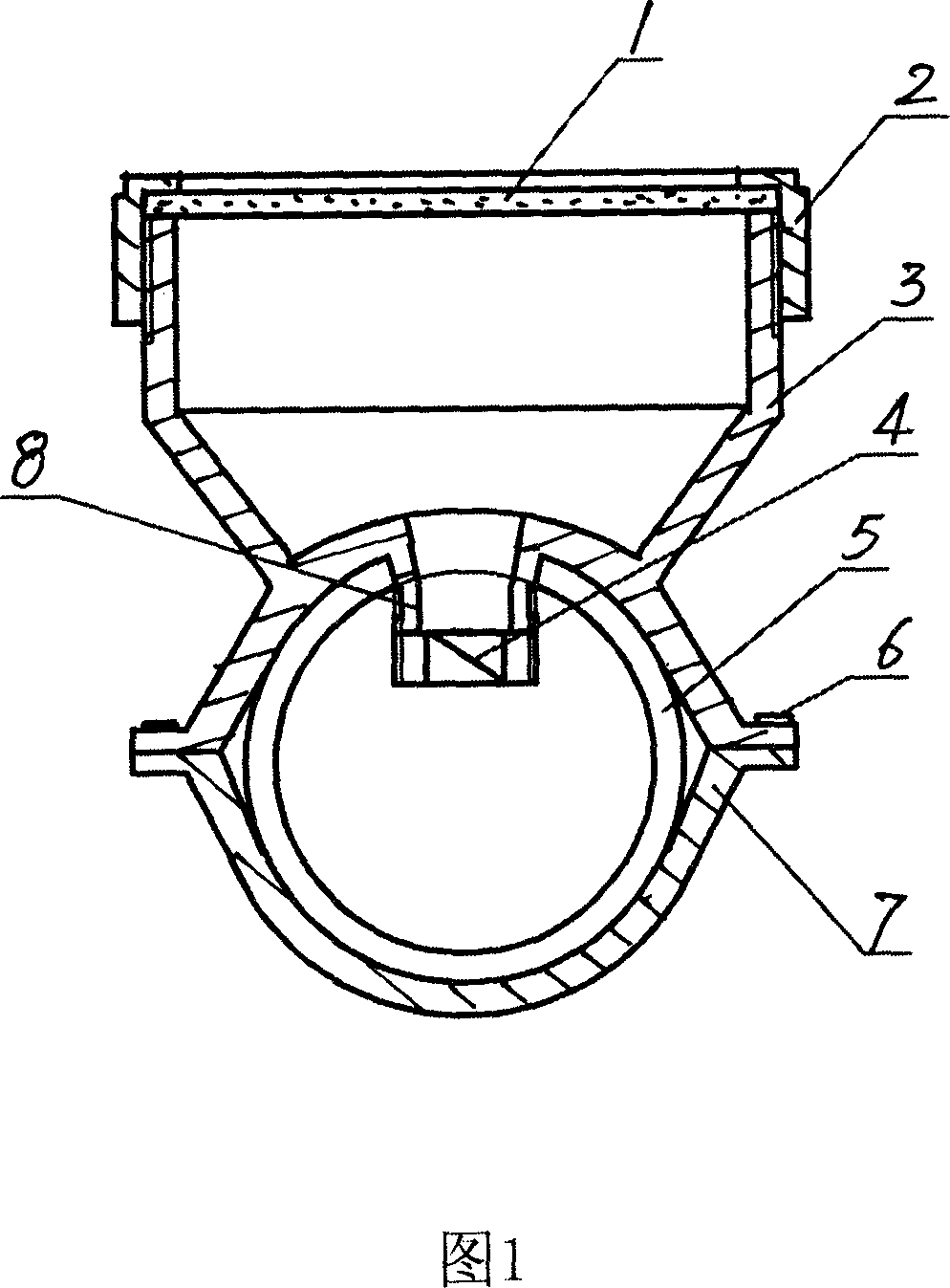

[0014] Embodiment 1, in Fig. 1, it is made up of aeration plate 1, outer jacket 2, inner sleeve 3, one-way ventilation valve 4, vent pipe 5, splint 7, and described outer jacket 2, inner sleeve 3, splint 7 are durable It is made of acid-base and corroded plastic. The lower end of the inner sleeve 3 is provided with an air inlet joint 8 in the middle, and its upper end is connected with the outer sleeve 2 with threads. The air inlet joint 8 on the top passes through the upper wall of the ventilation pipe 5 and is connected with the one-way ventilation valve 4. The aeration sheet 1 is planar, and the aeration sheet 1 is fixed between the outer casing 2 and the inner casing 3. The inside of the aerator 1 has honeycomb holes with a network structure, and the aerator 1 on the aerator is made of quartz sand, feldspar and resin as raw materials, and is manufactured according to the following method:

[0015] 1. First mix the two raw materials of 80% by weight, quartz sand with a part...

Embodiment 2

[0019] Example 2, the structure of the aerator is the same as that of Example 1, the difference is that: the aerator plate 1 is made of quartz sand, dolomite and glass water as raw materials, and is manufactured according to the following method:

[0020] 1. First mix the two raw materials of 95% by weight, quartz sand with a particle size of 30-70 mesh and 5% by weight of dolomite in a mixer,

[0021] 2. Add 6% of the total weight of glass water to the above mixture, and evenly mix and roll to form a mixture.

[0022] 3. Add the mixture into the mold and press it into a product blank.

[0023] 4. Send the billet into a high-temperature calcination furnace and calcine it at a temperature of 900-1300°C. After testing, the porosity of the aeration sheet is 30.6%.

Embodiment 3

[0024] Embodiment 3, the structure of the aerator is the same as that of Embodiment 1, the difference is that the aerator 1 is made of quartz sand, talc and resin as raw materials, and is manufactured according to the following method:

[0025] 1. First mix the two raw materials of quartz sand with a weight percentage of 55% and a particle size of 70-150 mesh and talc with a weight percentage of 45% in a mixer,

[0026] 2. Then add 3% resin of its total weight to the above mixture, and evenly mix and roll to form a mixture.

[0027] 3. Add the mixture into the mold and press it into a product blank.

[0028] 4. Send the billet into a high-temperature calcination furnace and calcine it at a temperature of 900-1300°C. After testing, the porosity of the aeration sheet is 33.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com