Installation of cooling and melting ice and snow for road surface and bridge road by using underground natural energy resource

A technology of natural energy and road and bridge decks, applied in heating devices, geothermal power generation, roads, etc., can solve hidden dangers of building safety, expensive machinery, waste of resources, etc., and achieve low operation and maintenance costs and long equipment life cycle The effect of long and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

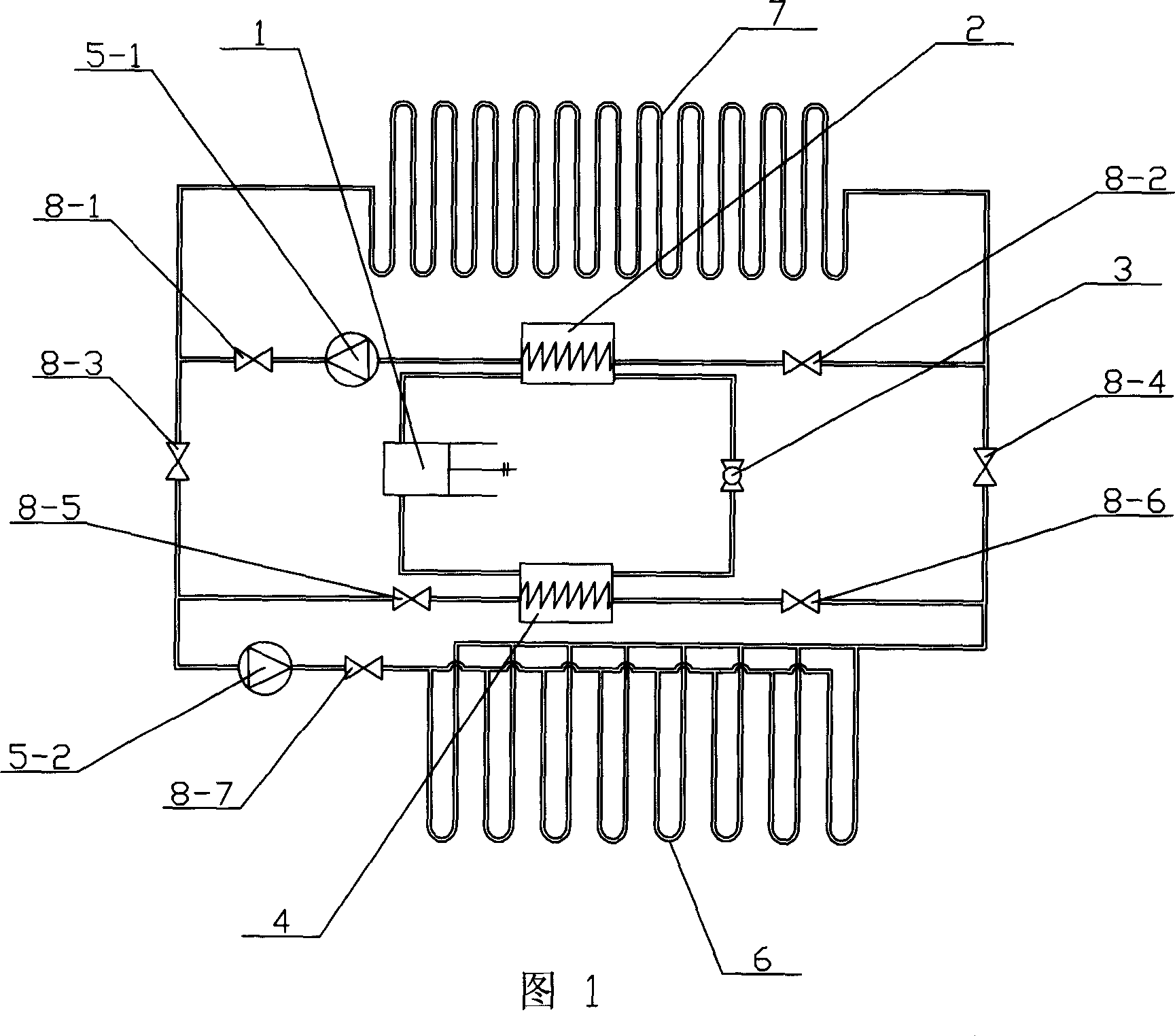

[0007] Specific implementation manner 1: This implementation manner is described in conjunction with FIG. 1 . This embodiment consists of a compressor 1, a condenser 2, an expansion valve 3, an evaporator 4, a circulation pump 5, a deep heat exchanger 6, a shallow heat exchanger 7, a first control valve 8-1, and a second control valve 8 -2. The third control valve 8-3, the fourth control valve 8-4, the fifth control valve 8-5, the sixth control valve 8-6 and the seventh control valve 8-7. The input end of the first circulation pump 5-1 is connected with the first output end of the tube side of the condenser 2, the output end of the first circulation pump 5-1 is connected with the input end of the first control valve 8-1, and the first control The output end of the valve 8-1 is respectively connected with the input end of the shallow heat exchanger 7 and one end of the third control valve 8-3, and the output end of the shallow heat exchanger 7 is connected with the second contr...

specific Embodiment approach 2

[0009] Specific Embodiment 2: This embodiment will be described in conjunction with FIG. 1 . In this embodiment, the input end of the compressor 1 is connected to the second output end of the evaporator 4 shell side, the output end of the compressor 1 is connected to the second input end of the condenser 2 shell side, and one end of the expansion valve 3 is connected to the evaporator 4 is connected to the second input end of the shell side, and the other end of the expansion valve 3 is connected to the second output end of the condenser 2 shell side.

[0010] Both the deep heat exchanger 6 and the shallow heat exchanger 7 are made of high-density polyethylene pipes or steel pipes. The embedding depth is 50mm-80mm from the ground (bridge) surface, which should be determined according to the load on the road (bridge) surface, the temperature of the heating fluid in the pipe and buried pipe. The underground energy-taking pipe is calculated based on the bridge (road) surface loa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com