Cluster controller for etching devices

A cluster controller and etching machine technology, applied in the direction of electrical program control, etc., can solve the problem of transmission module cluster controller without 200mm etching machine and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

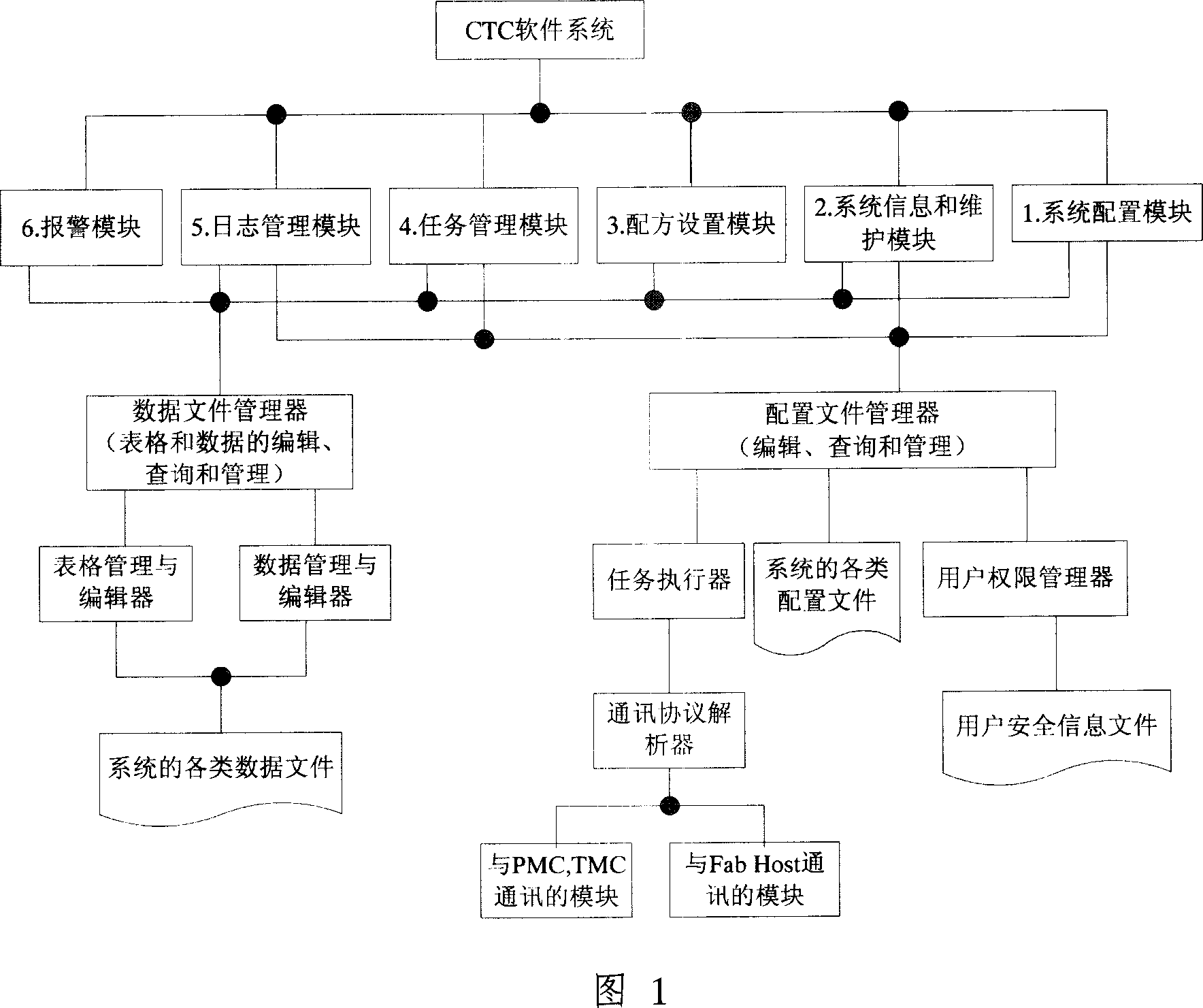

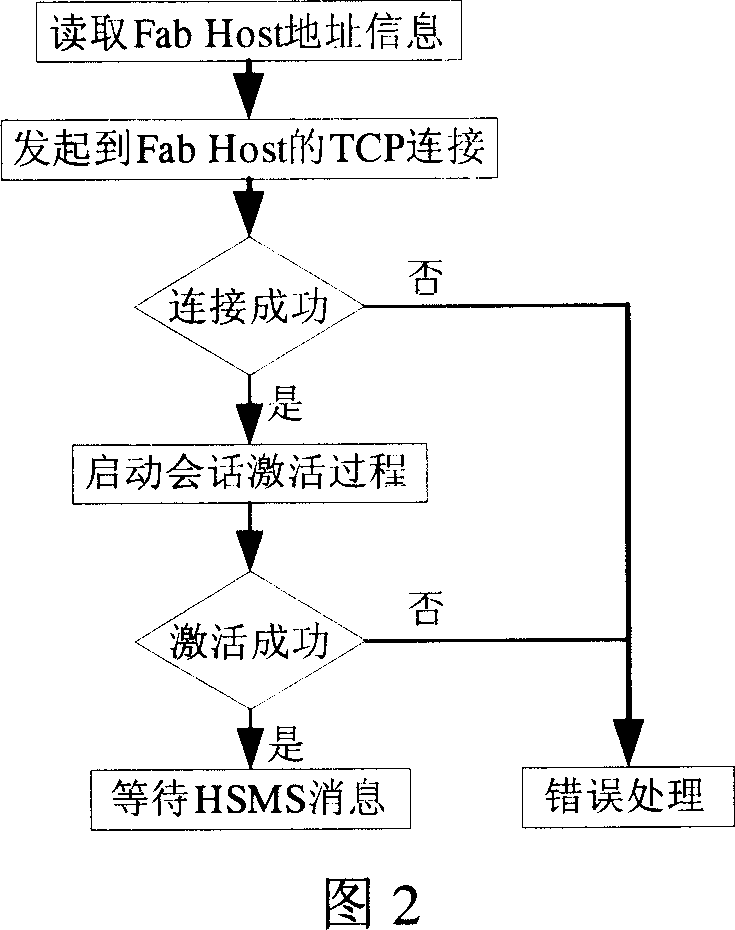

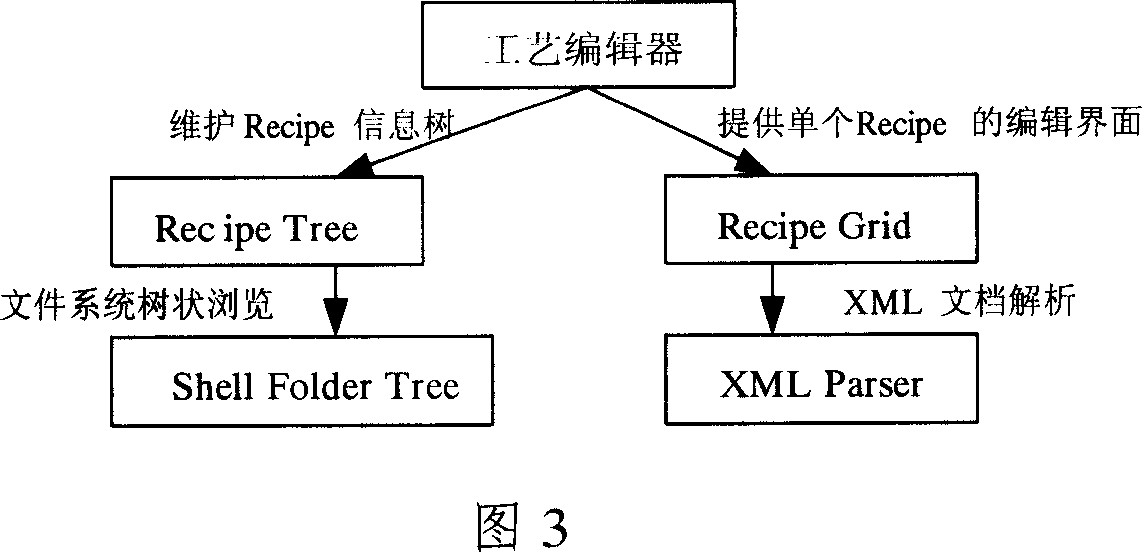

Method used

Image

Examples

Embodiment Construction

[0037] The etching machine cluster controller provided by the present invention will be described in detail below with reference to the drawings and embodiments.

[0038] The present invention includes an input device for inputting process flow and other data into the controller, a storage device for storing control programs, an output device for displaying monitoring status, a CPU for executing control information, and devices for connecting with etching machines at all levels. transmission device. In this embodiment, a general-purpose computer is used in conjunction with a control program to complete the realization of the entire controller. The general computer part adopts the basic configuration of CPU 2.4G, hard disk 200G, memory 512M, standard keyboard and display screen, equipped with a data connection interface, through which the control information transmission of the controller to the etching equipment and the etching equipment are completed. Transmission of process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com