Transpirationcooled wind driven generator stator

A technology of evaporative cooling and machine stator, which is applied to the static parts of the magnetic circuit, the shape/style/structure of the magnetic circuit, etc., can solve the problems of water difficulty, hot spots of heating components, and reduce the service life of winding insulation, etc., and achieve physical and chemical properties Good, no local hot spots, and the effect of suppressing corona discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

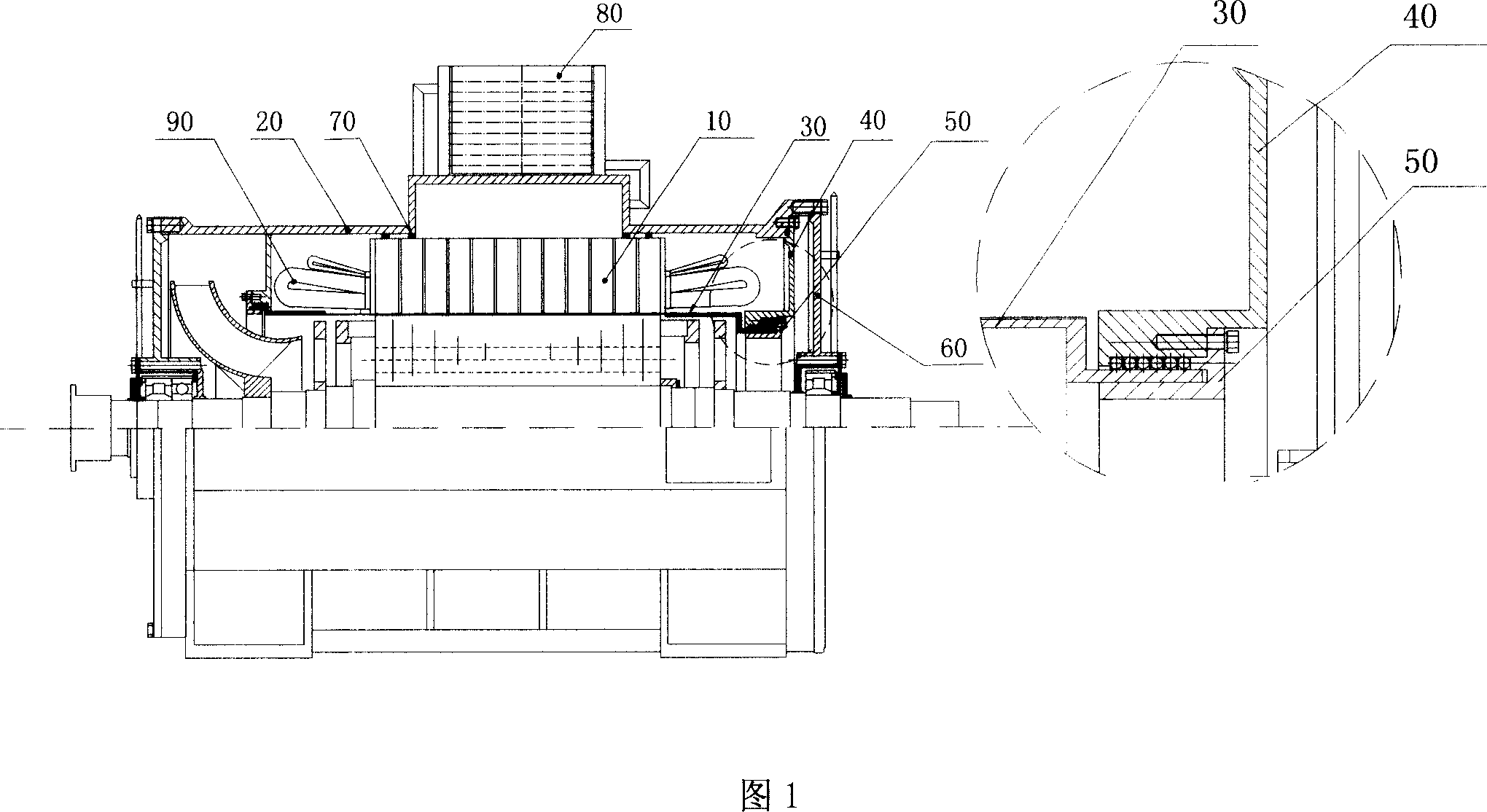

[0027] The specific implementation manner of the stator structure of the evaporative cooling wind power generator is described in conjunction with the accompanying drawings.

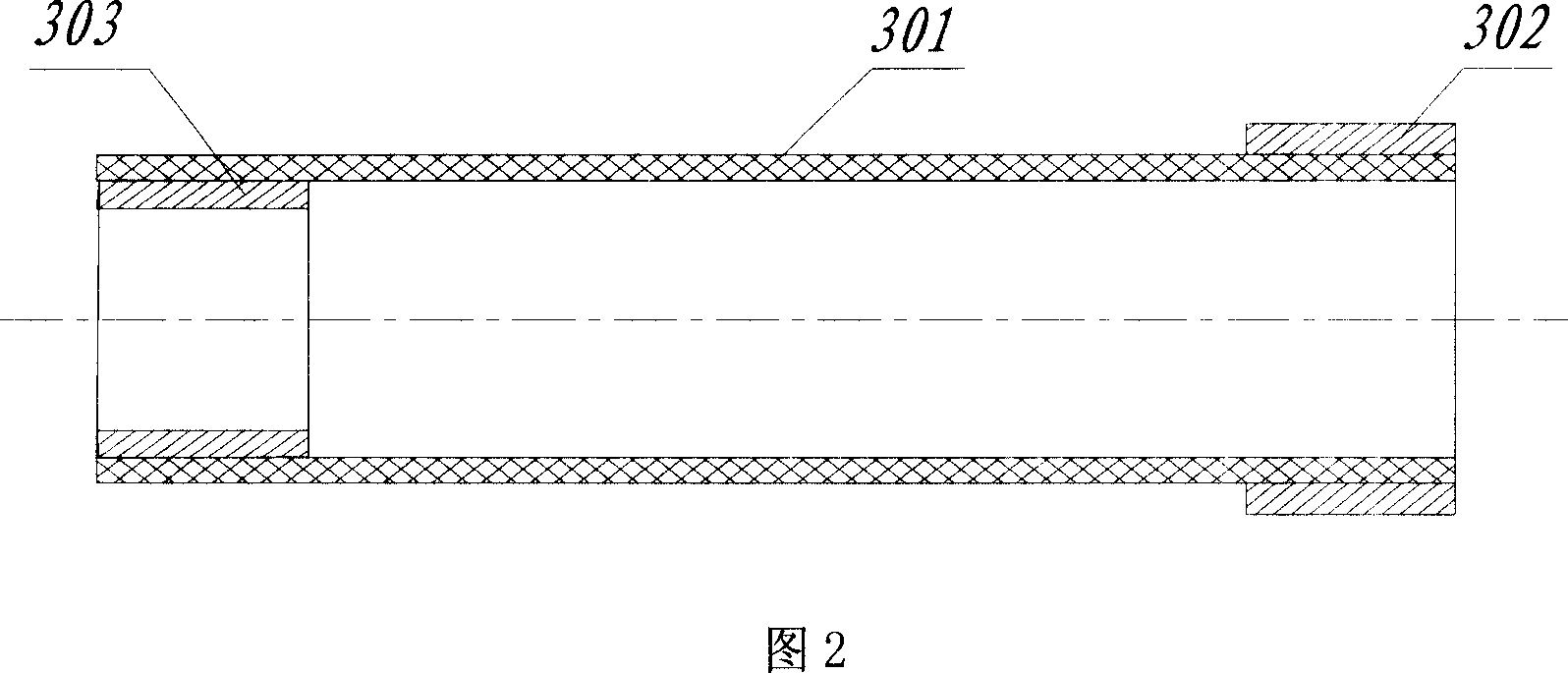

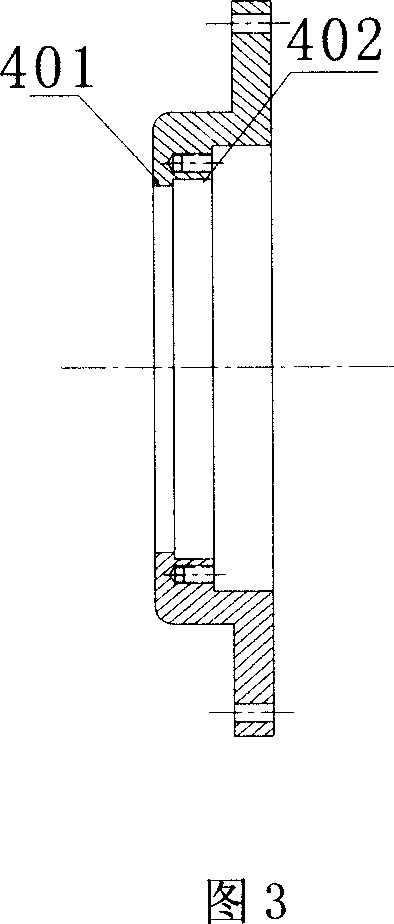

[0028] The evaporative cooling wind turbine stator includes the wind turbine stator and the evaporative cooling circuit. As shown in FIG. 1 , the main components constituting the stator of the wind power generator include a stator core segment 10 , a stator slot, a stator winding coil and a stator end winding 90 . The stator casing 20, the non-magnetic stainless steel isolation sleeve 30, the end sealing end cap 40 and the pressure stop ring 50 form the stator enclosed space, and the main components of the stator are installed in the stator enclosed space: the stator core segment 10 is installed in the stator casing 20 Inside, the non-magnetic stainless steel isolation sleeve 30 is installed at the inner circle of the stator core segment 10 , and the end sealing end caps 40 are installed at both ends of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com