Magnetic recording medium and its manufacturing method

A technology for a magnetic recording medium and a manufacturing method, applied in the directions of magnetic recording, magnetic recording layer, data recording, etc., can solve the problems of reduced recording and reproduction characteristics of the magnetic recording layer, excessively thick film thickness, etc., and achieves high designability and improved flashing. Sensation, the effect of improving the appearance design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

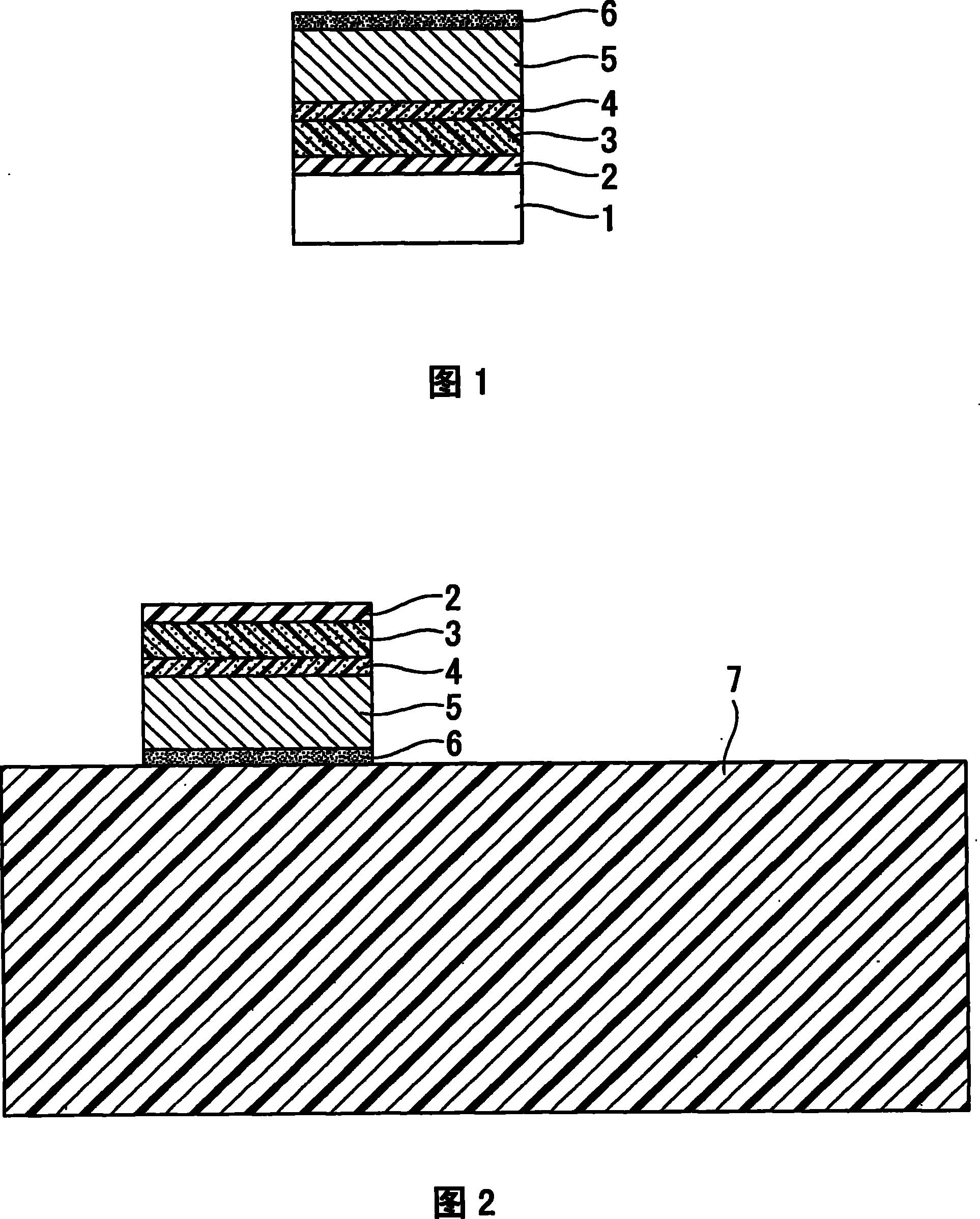

[0226] A 24μm thick polyethylene terephthalate film was used as the base material for replication, and the above-mentioned protective layer paint and bright coating layer were sequentially applied on one side of the film using a reverse coater. Paint [A], paint for light reflection quantity adjustment layer [A], paint for magnetic recording layer and adhesive paint, dry, respectively set protective layer, bright coating layer, light reflection quantity adjustment layer, magnetic recording layer and Adhesive layer. The film thickness of each layer after drying was formed such that the protective layer was 1 μm, the bright coating layer was 3 μm, the light reflection amount adjustment layer was 0.3 μm, the magnetic recording layer was 9 μm, and the adhesive layer was 1.5 μm. The film provided with the above-mentioned layers was cut to a width of 1 / 2 inch to produce a laminate for replication.

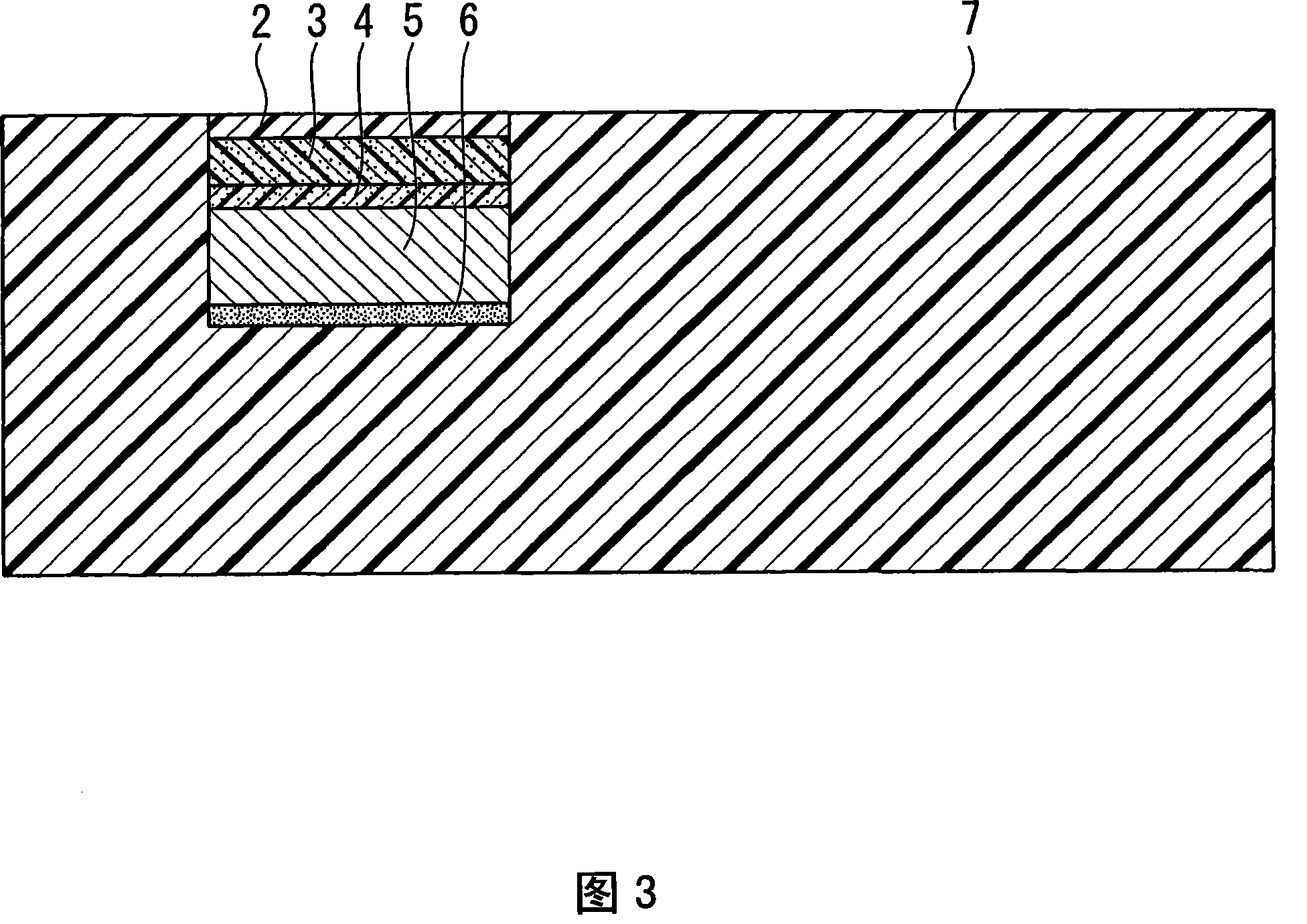

[0227] Using the copy laminate (replication tape) made as described above, the laminate...

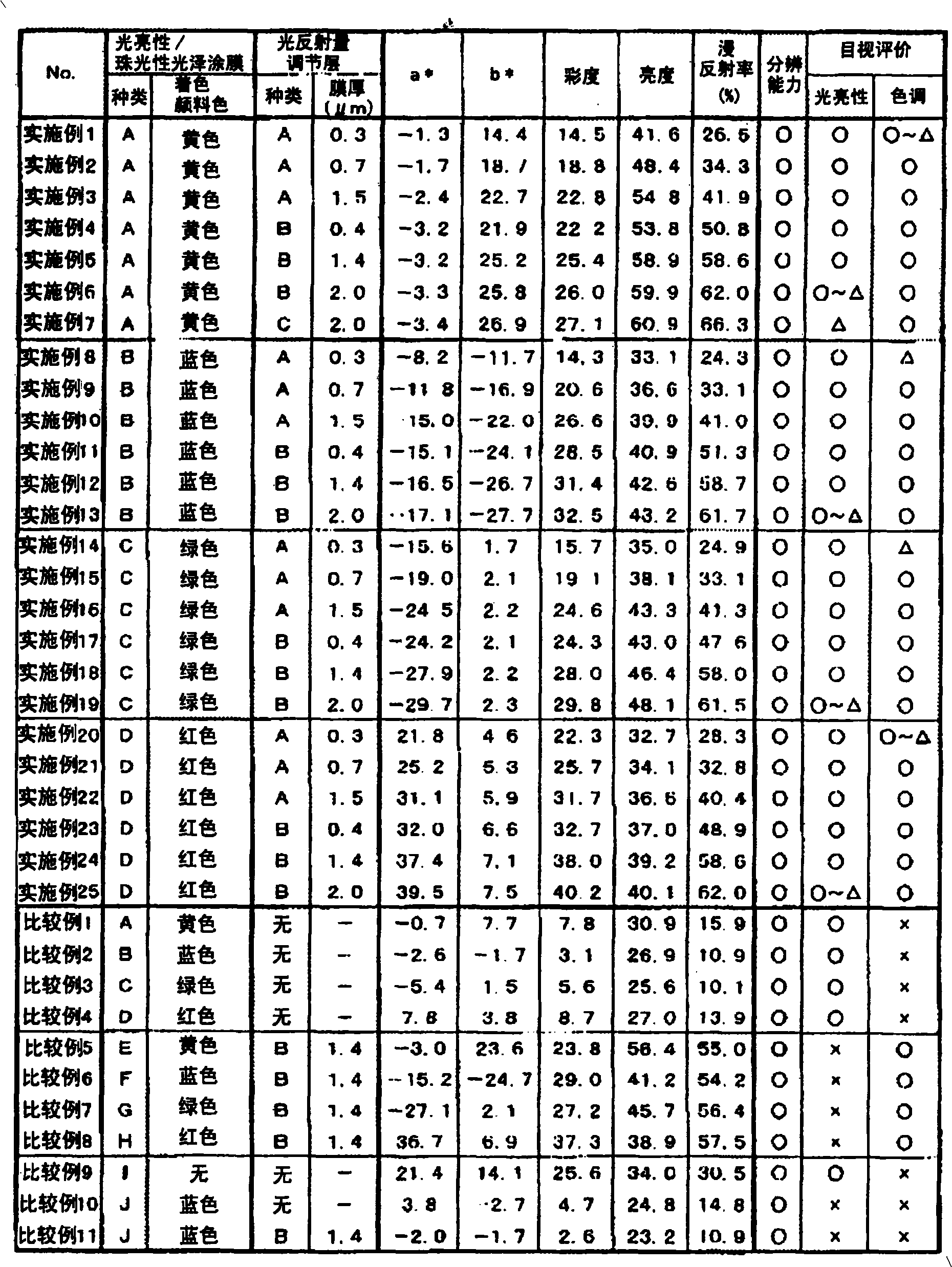

Embodiment 2~ Embodiment 25、 comparative example 1~ comparative example 11

[0229] Except that the following table 1 is used, the rest is the same as in Example 1, the copy laminates of Example 2 to Example 25 and Comparative Example 1 to Comparative Example 11 are produced, and are copied onto a card substrate and then hot pressed to produce a card Shaped magnetic recording medium.

[0230] ·Evaluation method

[0231] (Saturation)

[0232] The luminance (L) and chromaticity (a * , B * ), find the saturation C * = (a *2 +b *2 ). In addition, the larger the brightness value, the brighter the color, and the larger the saturation value, the more vivid the color.

[0233] (Diffuse reflectance)

[0234] The magnetic stripe part of the obtained magnetic card, that is, the area with the bright coating layer, was measured at each wavelength by the integrating sphere method of "Shimadzu Self-recording Spectrophotometer UV-3100" manufactured by Shimadzu Corporation. Wavelength 400nm The diffuse reflectance in incident light in the visible light range of ~700 nm, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com