CO2 laser welding apparatus

A carbon dioxide and laser welding technology, applied in laser welding equipment, lasers, welding equipment, etc., can solve problems such as overheating of the weld, uneven weld, poor welding, etc., and achieve strong bonding and smooth welds.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] A carbon dioxide laser welding device will be described below with reference to figures.

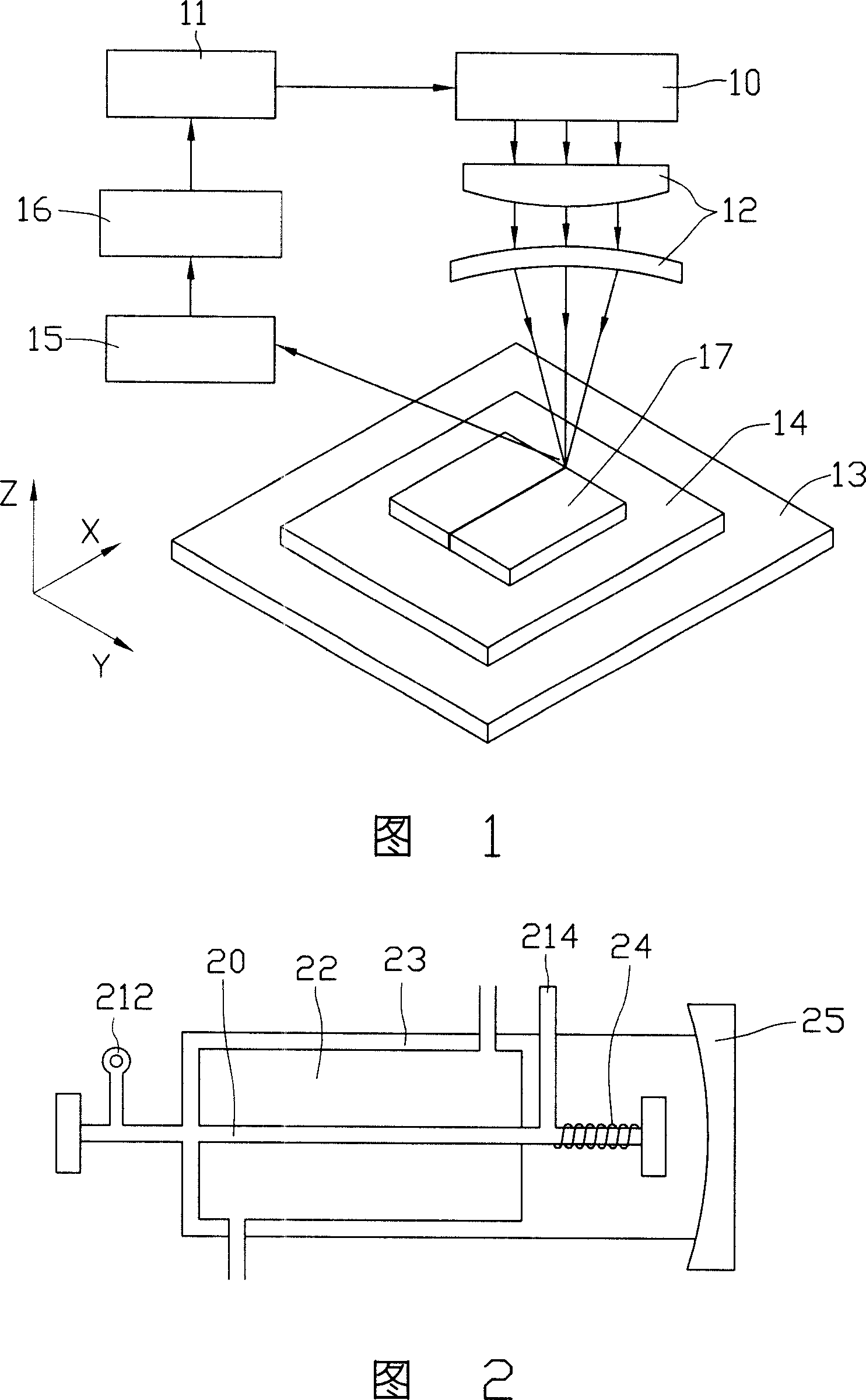

[0014] Please refer to FIG. 1 , the carbon dioxide laser welding device of the embodiment of the present invention includes a carbon dioxide laser 10 , a controller 11 , a lens system 12 and a stage 13 . Arrows in the figure indicate the direction of energy or signal transmission.

[0015] The carbon dioxide laser 10 is used to produce the high-energy laser beam needed for welding. Please refer to FIG. And the anode 214, the water cooling jacket 22 arranged on the surface of the discharge tube 20, and the gas storage sleeve 23 arranged outside the water cooling jacket 22. The discharge tube 20, the water cooling jacket 22 and the gas storage jacket 23 form a three-layer structure. The discharge tube 20 communicates with the gas storage sleeve 23 at one end close to the cathode 212 , and communicates with the gas storage sleeve 23 through the spiral air return pipe 24 at the othe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pulse width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com