Process for preparing highly efficient organic fertilizer from dungs and droppings

A technology of livestock and poultry manure and organic fertilizer, applied in the directions of organic fertilizer, application, fertilization device, etc., can solve the problems of low fertilizer efficiency, high cost, exposure to sunlight or mechanical drying, etc., and achieve high fertilizer efficiency, low cost and shorten the fermentation cycle. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

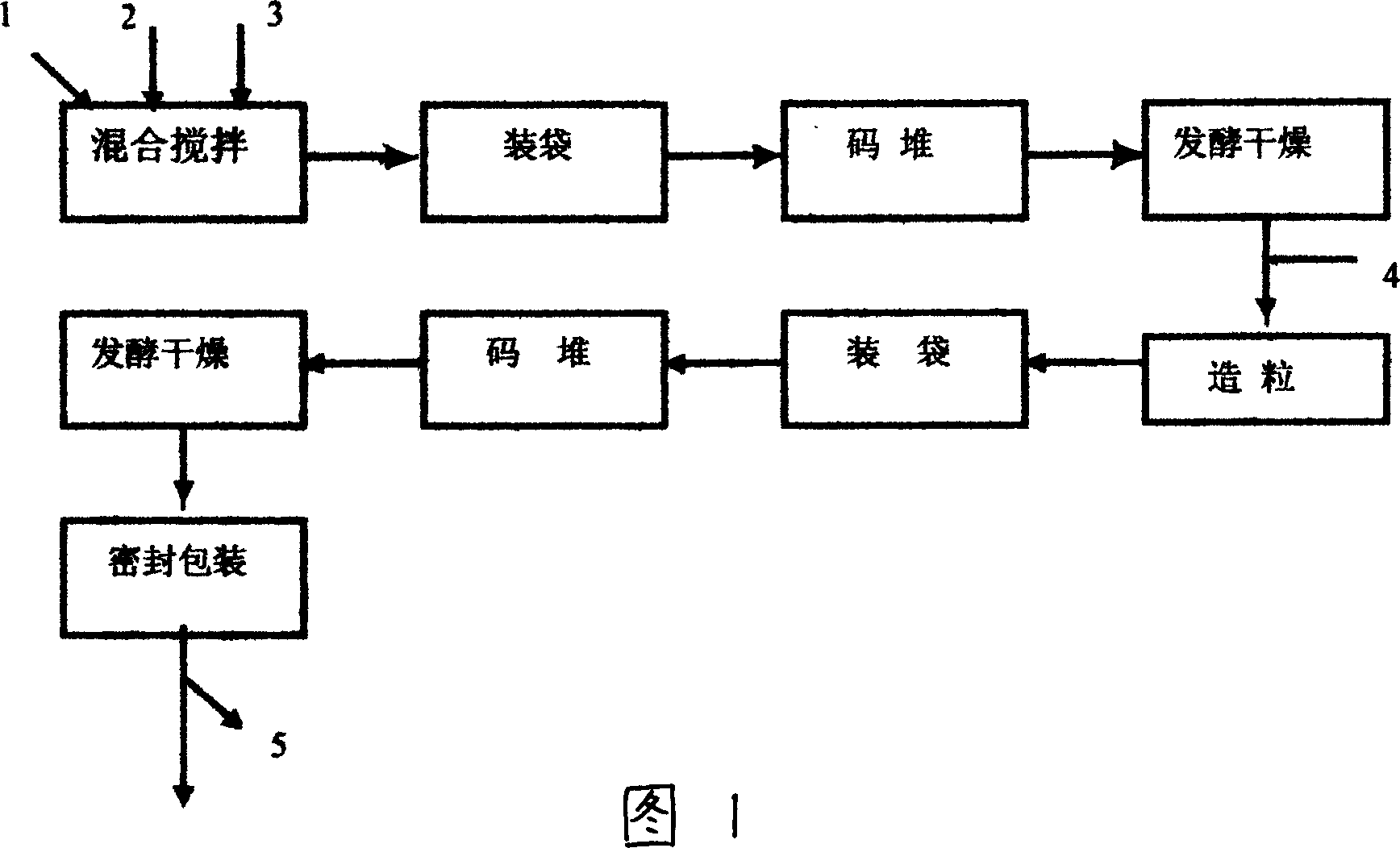

Image

Examples

example 1

[0031] Raw materials are mixed according to 50% pig manure (dry), 20% tobacco powder, and 30% rice bran, add 3‰EM biological bacteria preparation, mix evenly, pack about 25 kg in woven bags, and pile up regularly about 1.5 meters high After 3 days, the temperature in the pile can reach 60-70°C, and the woven bags are piled up irregularly, with a pile height of about 1.5 meters; after 10 days, the pile is turned over irregularly; %; According to the needs of customers, you can choose to add appropriate amount of organic or inorganic fertilizers, and trace elements, or directly granulate without adding any substances; then, bag them again and stack them irregularly for 7 days. The stack height is about 1.5 meters and the moisture content is average. Below 20%; packed in oxygen barrier to get finished product. Both the production process and the finished product are not smelly.

example 2

[0033] Raw material pig manure is substituted with cow manure and chicken manure among the example 1, and other preparation methods are identical. Both the production process and the finished product are not smelly.

example 3

[0035] In Example 1, the raw materials are proportioned according to 50% pig manure, 30% tobacco powder, and 20% rice bran, and the other preparation methods are the same. Slight odor during production.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com