Improved sulfur envelope type slow release fertilizer

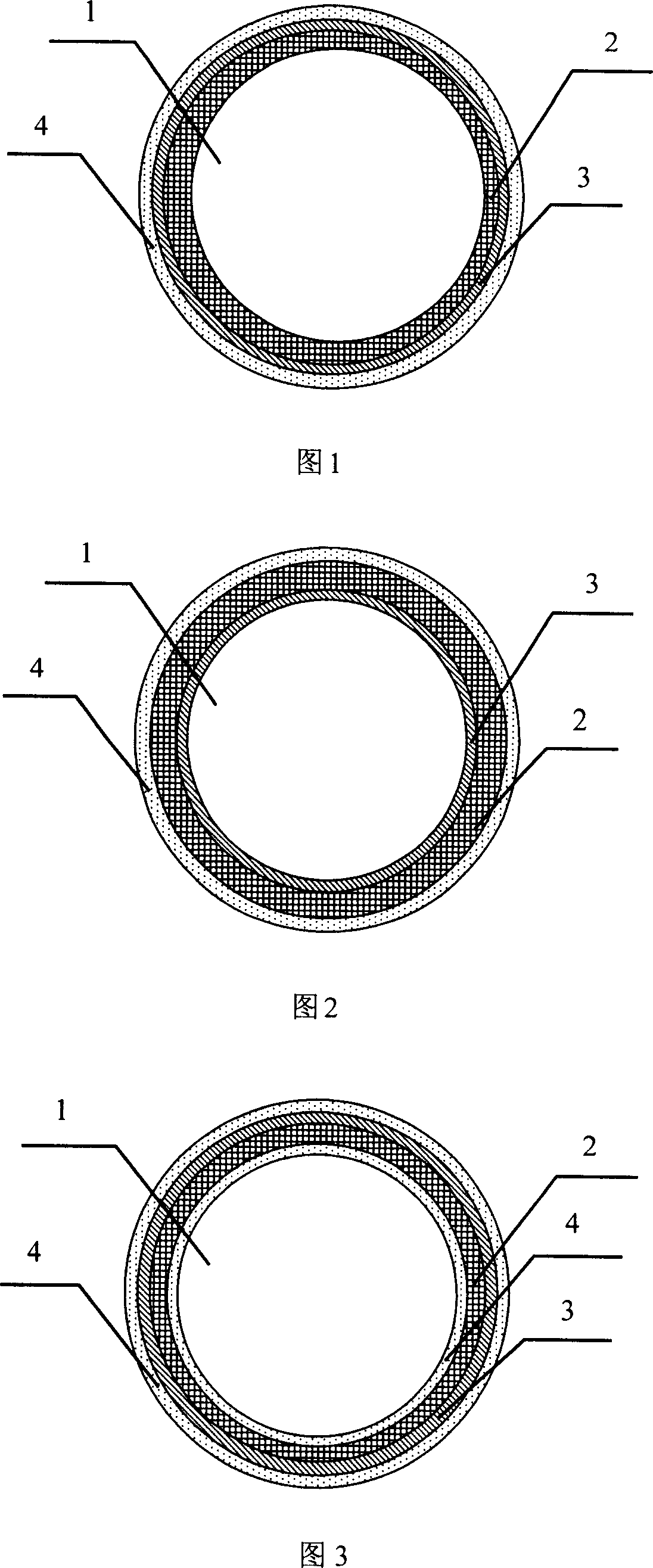

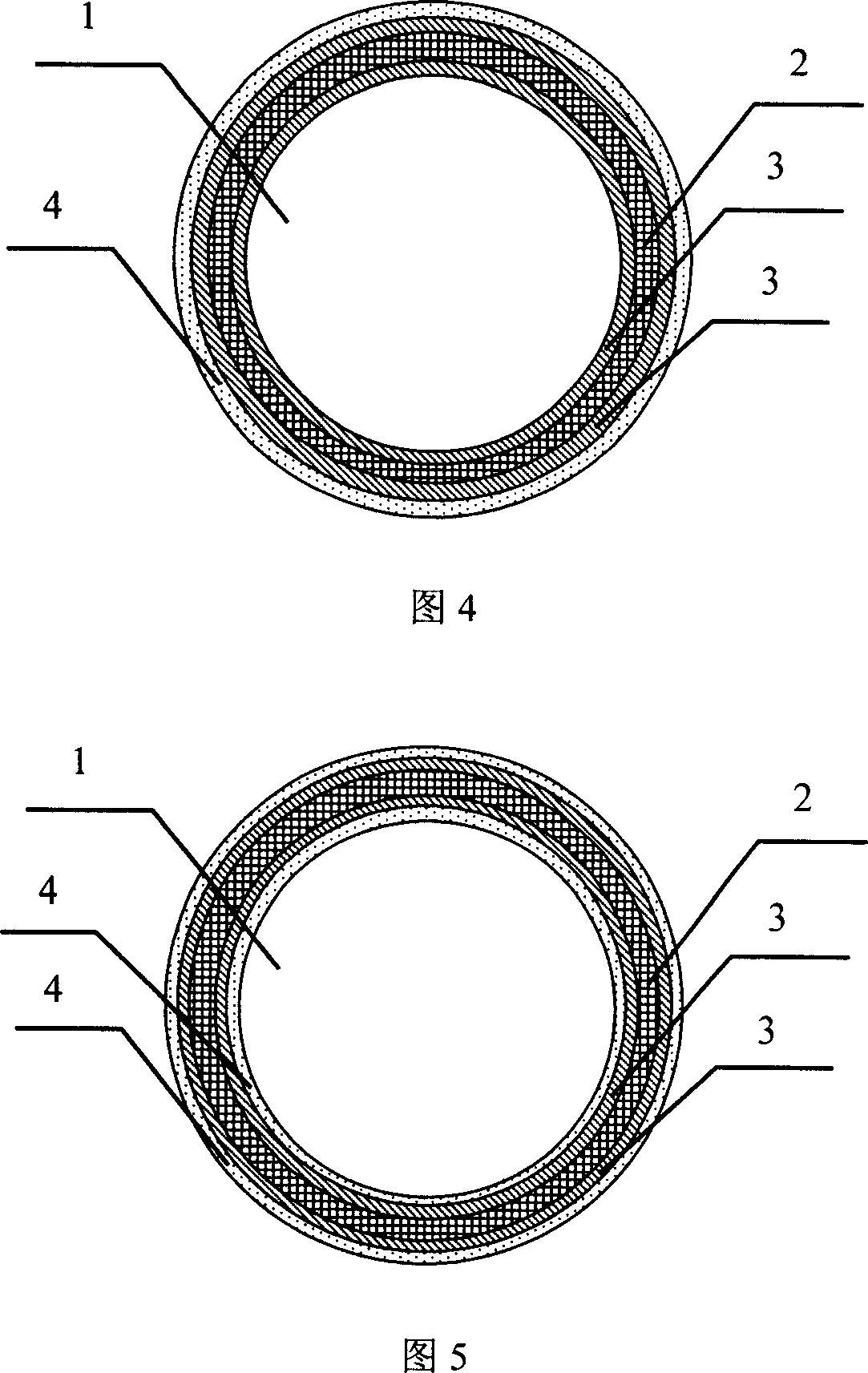

A slow-release fertilizer and coating technology, which is applied in the field of coated slow-release fertilizers and improved sulfur composite coated slow-release fertilizers, can solve the problem that the release period of sulfur composite coated slow-release fertilizers is not very long, and achieves low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

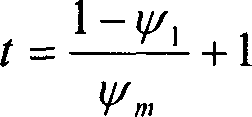

[0037] Add granular industrial urea with a particle size of 2.0 to 4.0mm into the fluidized bed coating equipment, and keep the granular urea in a boiling state, and keep the temperature of the granular urea in the fluidized bed at 55°C. Slowly spray molten sulfur at about 150°C on the surface of granular urea until the quality of the formed sulfur film reaches 15% of the total mass of the final product improved sulfur composite coated slow-release urea. Then, spray paraffin melt (paraffin wax melting point is 60 ℃) on the surface of the sulfur film layer, and spray until the quality of the formed paraffin film layer reaches 2% of the total mass of the final product improved sulfur composite coating type slow-release urea. Finally, spray the mixture of 4,4-diphenylmethane diisocyanate, triethanolamine and diethylene glycol on the surface of the paraffin film layer (the molar ratio of triethanolamine: diethylene glycol is 0.2: 1, the molar ratio of -NCO: -OH Ratio is 1.1: 1) me...

Embodiment 2

[0039] Add granular industrial urea with a particle size of 2.0 to 4.0mm into the drum coating equipment with a temperature control of 95°C, and rotate the drum (rotating speed 40r / min) to make the granular urea flow in the drum. Slowly spray molten sulfur at about 150°C on the surface of granular urea until the quality of the formed sulfur film reaches 13% of the total mass of the final product improved sulfur composite coated slow-release urea. Then, the mixed emulsion (styrene-butadiene rubber in the mixed emulsion: the mass ratio of polystyrene is 1: 3) that is formed by styrene-butadiene rubber emulsion and polystyrene emulsion is sprayed on the surface of the sulfur film layer, spray until the styrene-butadiene rubber that forms- The quality of the polystyrene mixture film layer reaches 1.5% of the total mass of the final product improved sulfur composite coating type slow-release urea, and the film layer is fully dried to remove water contained in the film layer. Finall...

Embodiment 3

[0041] Add granular industrial urea with a particle size of 2.0 to 4.0mm into the drum coating equipment with a temperature control of 65°C, and rotate the drum (rotating speed 40r / min) to make the granular urea flow in the drum. Slowly spray molten sulfur at about 150°C on the surface of granular urea until the quality of the formed sulfur film reaches 11% of the total mass of the final product improved sulfur composite coated slow-release urea. Then, spray the solvent gasoline solution of butadiene rubber on the surface of the sulfur film layer, spray until the quality of the butadiene rubber film layer formed reaches 1.5% of the total mass of the final product improved sulfur composite coating type slow-release urea, fully dry and remove the film Layer solvent gasoline. Finally, spray S-739S type unsaturated polyester prepreg containing 10% plasticizer butyl phthalate benzyl ester, 1.5% benzoyl peroxide and a small amount of catalyst on the surface of butadiene rubber raw r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com