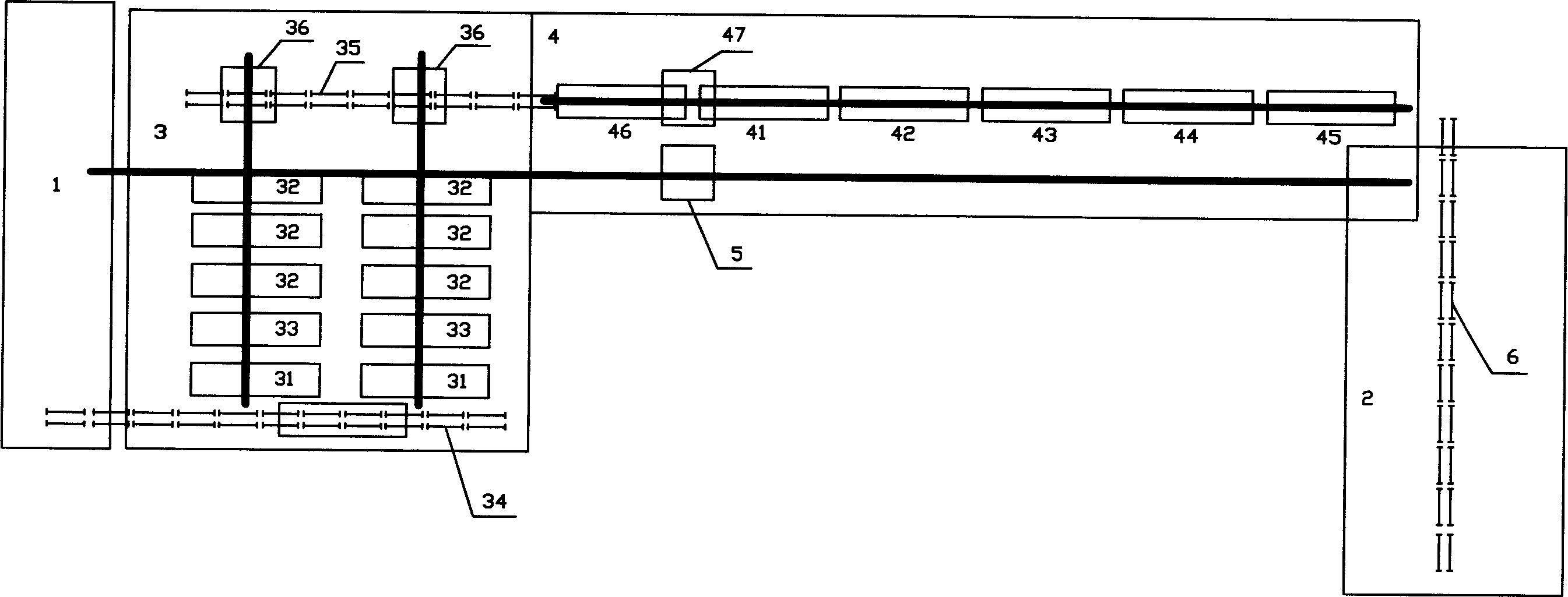

Hot dip galvanizing production method and production line therefor

A technology of hot-dip galvanizing and production method, which is applied in the direction of hot-dip galvanizing, superimposed layer plating, coating, etc., can solve the problems of harsh use environment, complicated situation, low efficiency, etc., and achieve high production efficiency and structural Reasonable layout effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The hot-dip galvanizing production method of the present invention comprises the steps of degreasing treatment, pickling and rust removal, fluxing treatment, drying, hot-dip galvanizing, water cooling, passivation treatment and the like. The steps are described in detail below:

[0019] A) degreasing treatment: put the workpiece into the degreasing tank with degreasing liquid through rail transport vehicles and driving cars, set the degreasing time according to the amount of oil on the surface of the workpiece, and then send the degreasing workpiece into the clear water tank for cleaning;

[0020] B) pickling and derusting; hoist the above-mentioned degreasing and water-washed workpieces with a crane, put them in a hydrochloric acid tank for pickling, and the pickling time depends on the degree of rust on the workpiece surface; the pickled workpieces are then sent to the washing tank Internal flushing;

[0021] C) plating fluxing treatment; the workpiece rinsed after t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com