Pressure-release cylinder-variable oil-saving engine

An engine, closed cylinder technology, applied in engine components, engine control, combustion engines, etc., can solve problems such as inability to promote, consume effective power, etc., and achieve the effect of being beneficial to startup, environmental protection, and improving load rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

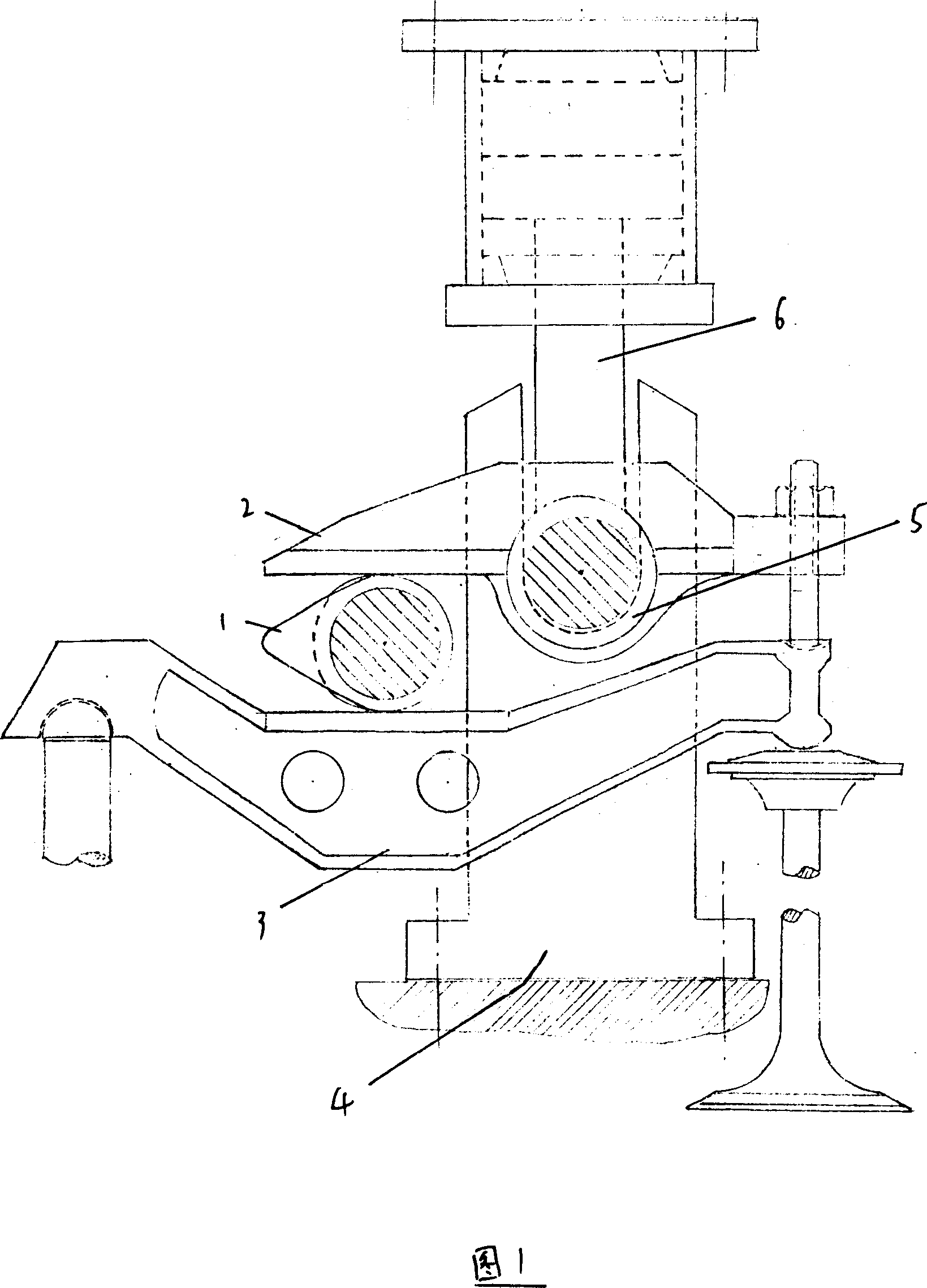

[0011] The engine adopts the overhead camshaft swing arm valve mechanism, and a decompression rocker arm 2 is newly added on each cam 1 of the part of the cylinder that needs to be closed, and one end of the decompression rocker arm 2 is pressed against the cam 1 opposite the swing arm 3 The other end of the decompression rocker arm 2 is pressed on the swing arm 3 above the valve stem, and the decompression rocker arm shaft is installed on the U-shaped bracket 4 between the camshaft and the valve. In the U-shaped groove 5 that can move up and down therein, its lifting is controlled with a hydraulic push rod 6 . When the decompression rocker arm 2 shaft was in the lifting state, the decompression rocker arm 2 was separated from the cam 1 and the swing arm 3, that is, the decompression rear rocker arm 2 did not work, and the engine was in a normal working state. When the engine is light-loaded or empty-loaded, first cut off the fuel or the mixed gas and then switch to the exhaus...

example 2

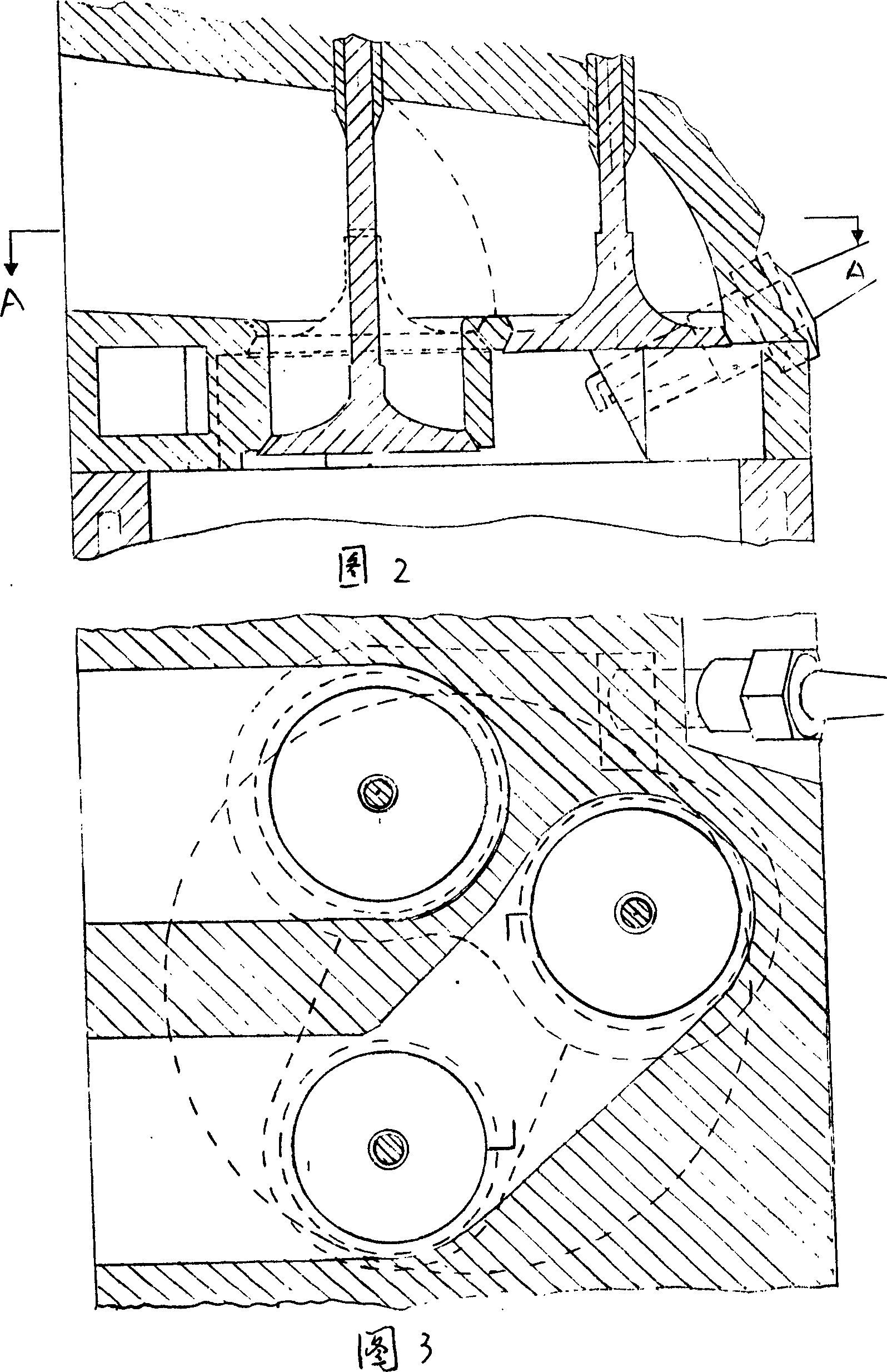

[0014] The engine adopts a bathtub-shaped combustion chamber, and the combustion chamber to be closed is rotated at a certain angle with the intake valve as the axis, so that the exhaust valve is placed outside the combustion chamber, and the exhaust valve seat is slightly lifted to form a shallow pit. Connected with the combustion chamber, add a decompression valve 7 in the combustion chamber, the decompression valve 7 is controlled by a hydraulic push rod or a pneumatic push rod, and is linked with the oil cut-off switch or the mixed gas switch; the air passage of the decompression valve is connected with the The exhaust duct is connected. When the cylinder is working normally, the decompression valve 7 is closed; when the cylinder needs to be closed under light load or no load, while cutting off the supply of fuel, air or mixed gas, control the hydraulic push rod to press down the decompression valve 7 and open it for a long time , At this time, the closed cylinder communic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com