Testing method for serum density of serum pot or fume desulfurating absorption tower

A desulfurization absorption tower, density detection technology, applied in the direction of determining specific gravity by measuring pressure difference, can solve the problems of inability to distinguish suspended solids and dissolved solids, false signals, etc., to overcome application limitations, accurate measurement, and eliminate measurement errors Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

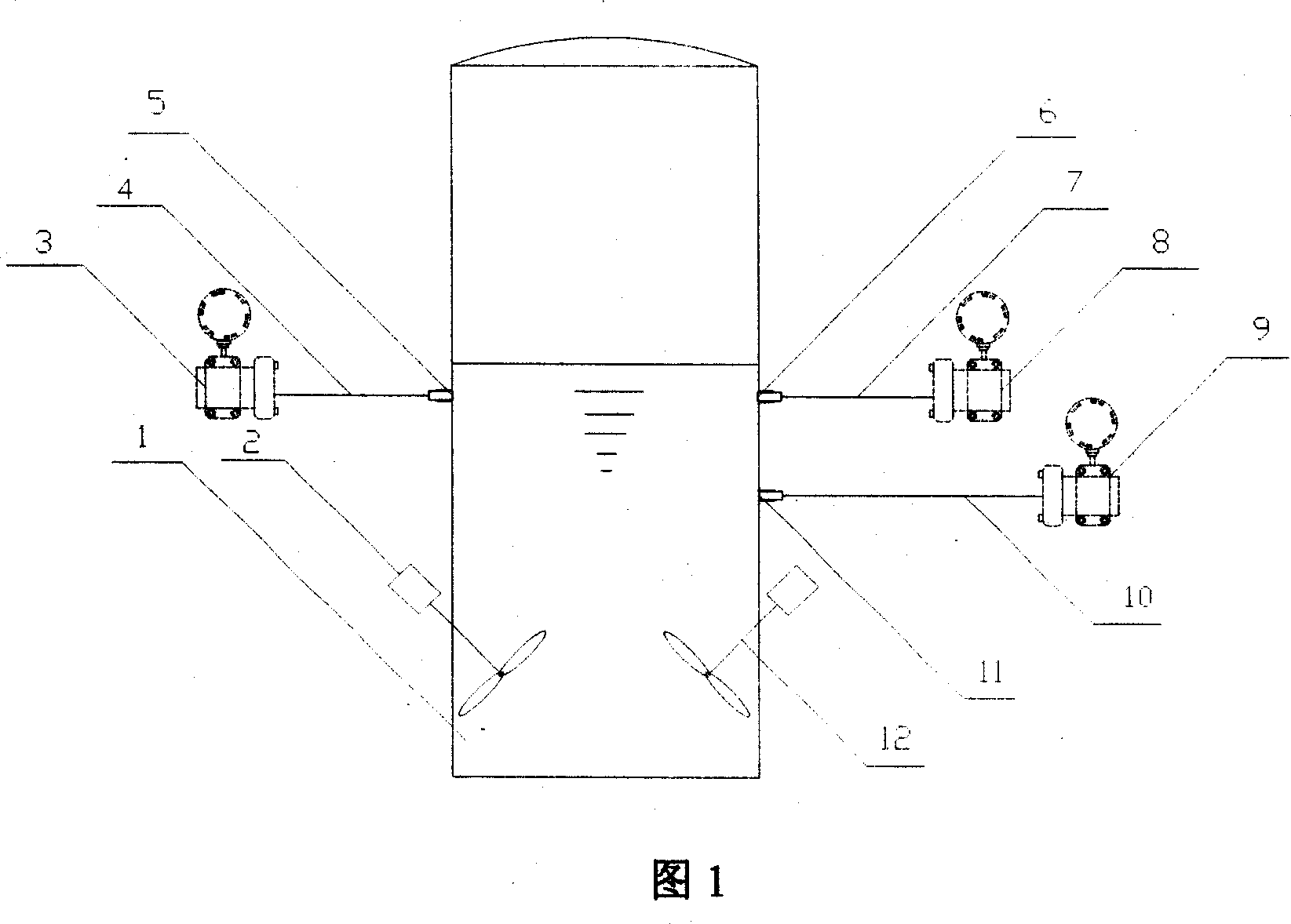

[0009] On the flue gas desulfurization absorption tower or slurry tank, according to the monitoring system design specifications, a plurality of pressure measurement points are evenly distributed along the circumferential direction of the same height, and the pressure signal is sent to the monitoring system through a differential pressure transmitter. These pressure measuring points can be used to measure the density of the absorption tower or slurry tank without adding other detection equipment, and realize pressure measurement and slurry density detection at the same time. The technical solution is: use the existing pressure measurement device and pressure transmitter on the flue gas desulfurization absorption tower or slurry tank, select any one of the measurement point openings to be placed at a low position, and avoid the installation position of the agitator. For the flue gas desulfurization absorption tower or the slurry tank, in order to prevent the solid deposition in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com