Micro channel electrode and miniflow control analysis chip

A technology of microfluidic analysis and microchannel, which is applied in the direction of material electrochemical variables, material inspection products, biological testing, etc., can solve the problems of high mask precision requirements, high channel alignment technology, and high product scrap rate. Achieve the effect of high aspect ratio, simple structure and easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

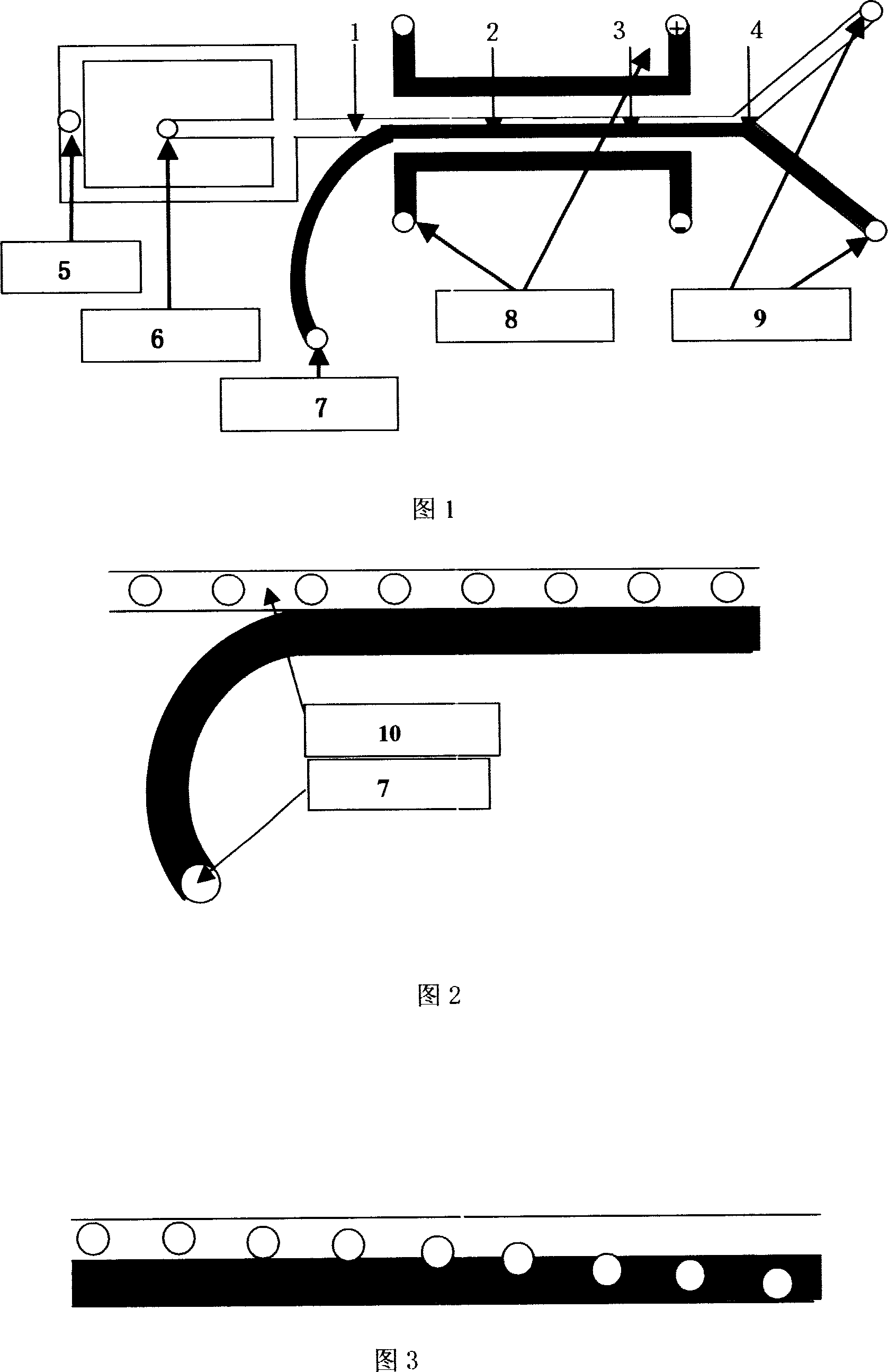

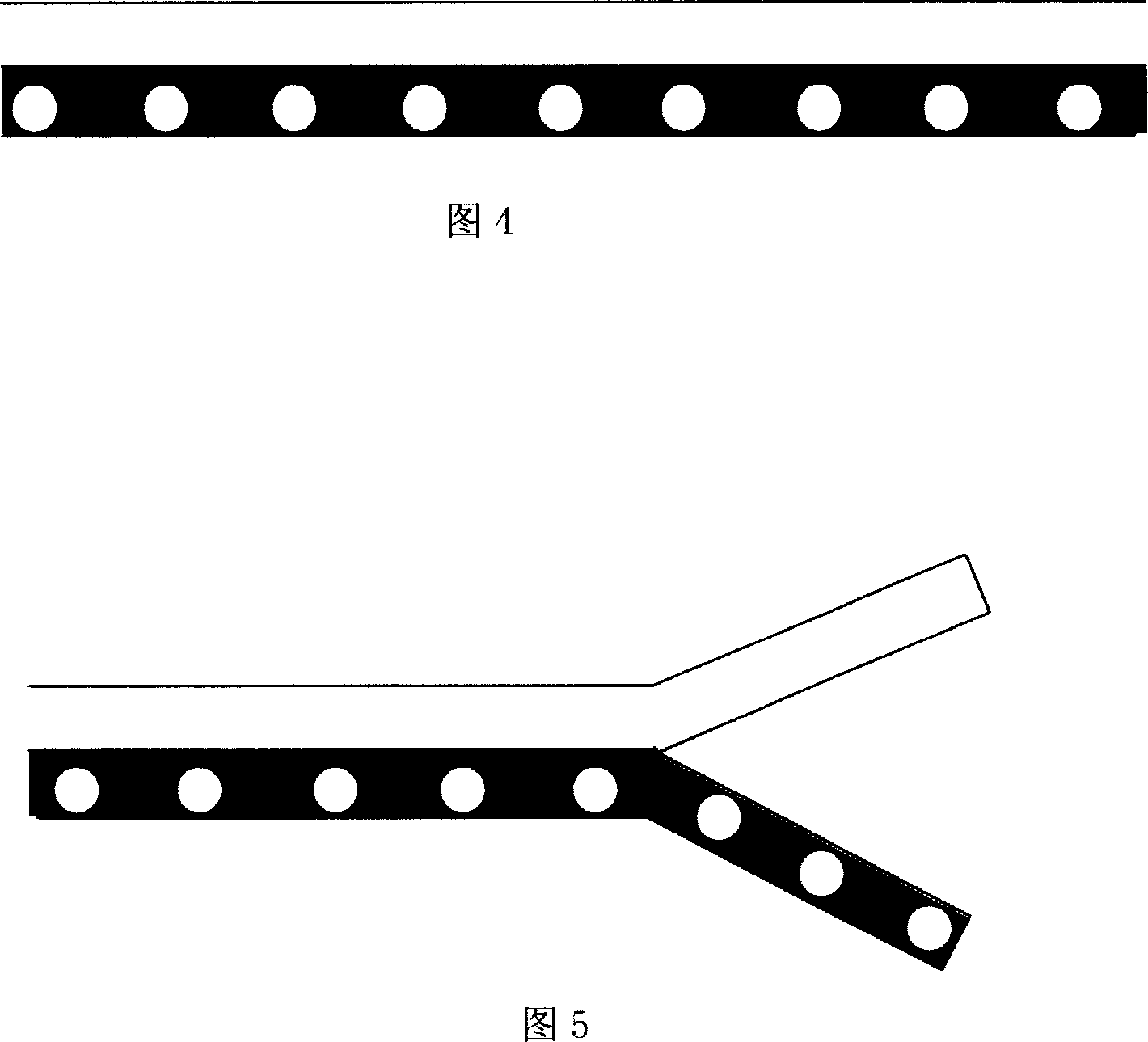

[0016] The technical solutions of the present invention will be further described below with reference to specific embodiments.

[0017] The micro-channel electrode of the embodiment of the present invention has an electrode in the channel of the base, and is characterized in that: the electrode in the channel is composed of a conductive fluid and a conductor hole pin, and the conductor hole pin is inserted into the conductive fluid; the conductive fluid is: One of the following: liquid electrolyte, liquid metal, PDMS prepolymer mixed with conductive substances, and magnetic fluid.

[0018] The microfluidic analysis chip of the present invention has a fluid channel in the chip, and two electrode channels in parallel next to the fluid channel are characterized in that: the electrodes in the channel are composed of conductive fluid and conductor holes, and the conductor holes are inserted into the holes. In conductive fluids; liquid electrolytes, liquid metals, PDMS prepolymers ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com