Real-time measuring device for high precision thin-film stress and measuring method

A thin-film stress and real-time measurement technology is applied in the direction of measuring devices, measurement of the change force of the optical properties of the material when it is stressed, and instruments. It can solve the problems of less understanding of stress changes and insufficient depth of thin-film stress. Easy adjustment and maintenance, friendly interface, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below with reference to the accompanying drawings and embodiments, but the protection scope of the present invention should not be limited by this.

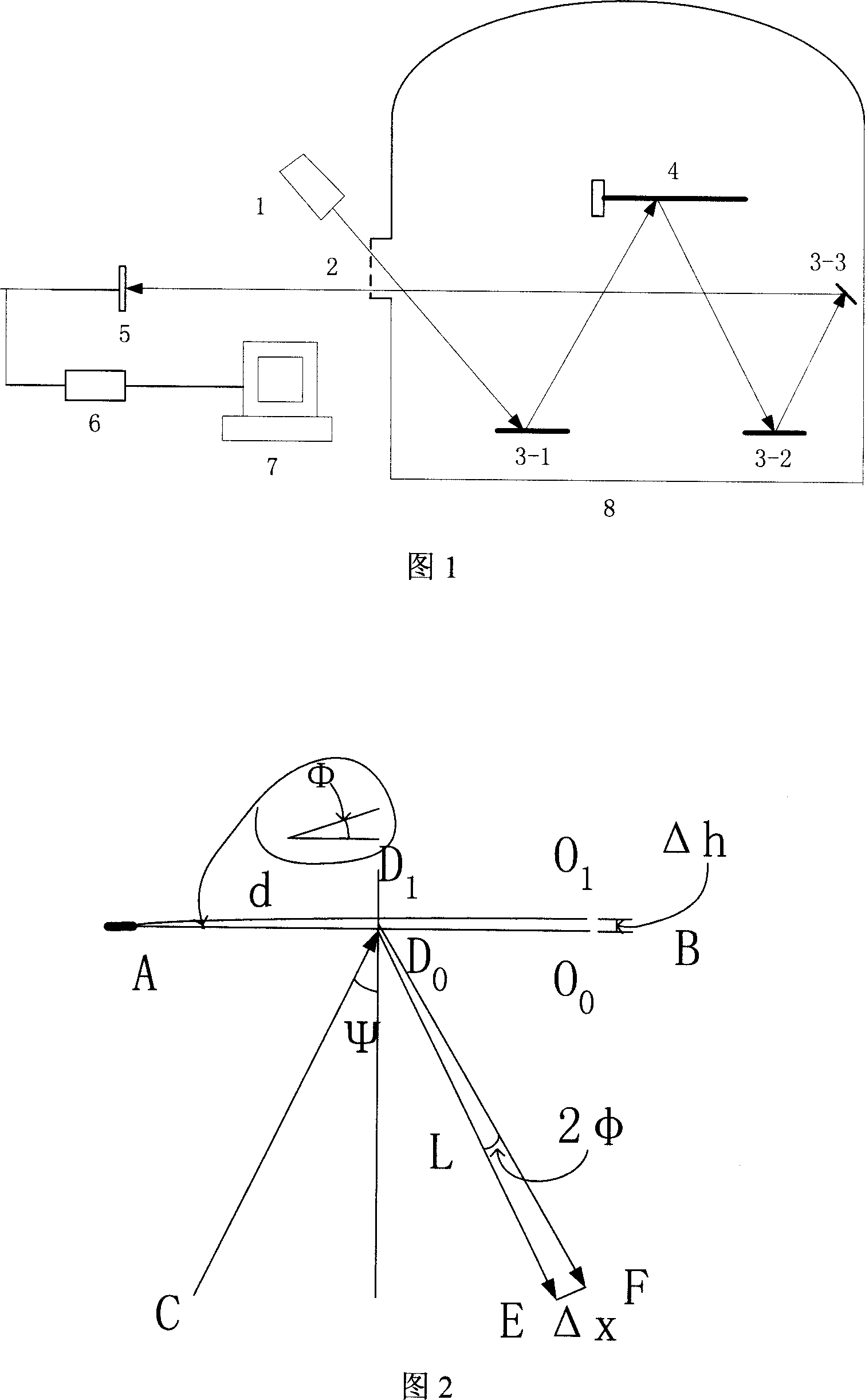

[0027] Please refer to FIG. 1 first. FIG. 1 is a schematic diagram of the overall structure of the high-precision thin-film stress real-time measuring device of the present invention. The second reflecting mirror 3-2, the third reflecting mirror 3-3, the photoelectric potential-sensitive detector 5, the A / D data acquisition card 6 and the computer 7 are composed, and their positional relationship is as follows: Observation in the vacuum chamber 8 of any coating machine The He-Ne laser 1, the photoelectric potential-sensitive detector 5, the A / D data acquisition card 6 and the computer 7 are arranged outside the window 2, and the first reflecting mirror 3-1 is arranged in the vacuum chamber 8 of the coating machine. , the second reflection mirror 3-2, the third reflection mirr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com