Novel semiconductor material In-Ga-N surface barrier type solar battery and its preparation method

A surface barrier, solar cell technology, applied in semiconductor devices, circuits, photovoltaic power generation, etc., can solve the problems of solar cells that have not been reported in domestic and foreign literature, and achieve the effects of reducing interface recombination, high absorption coefficient, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

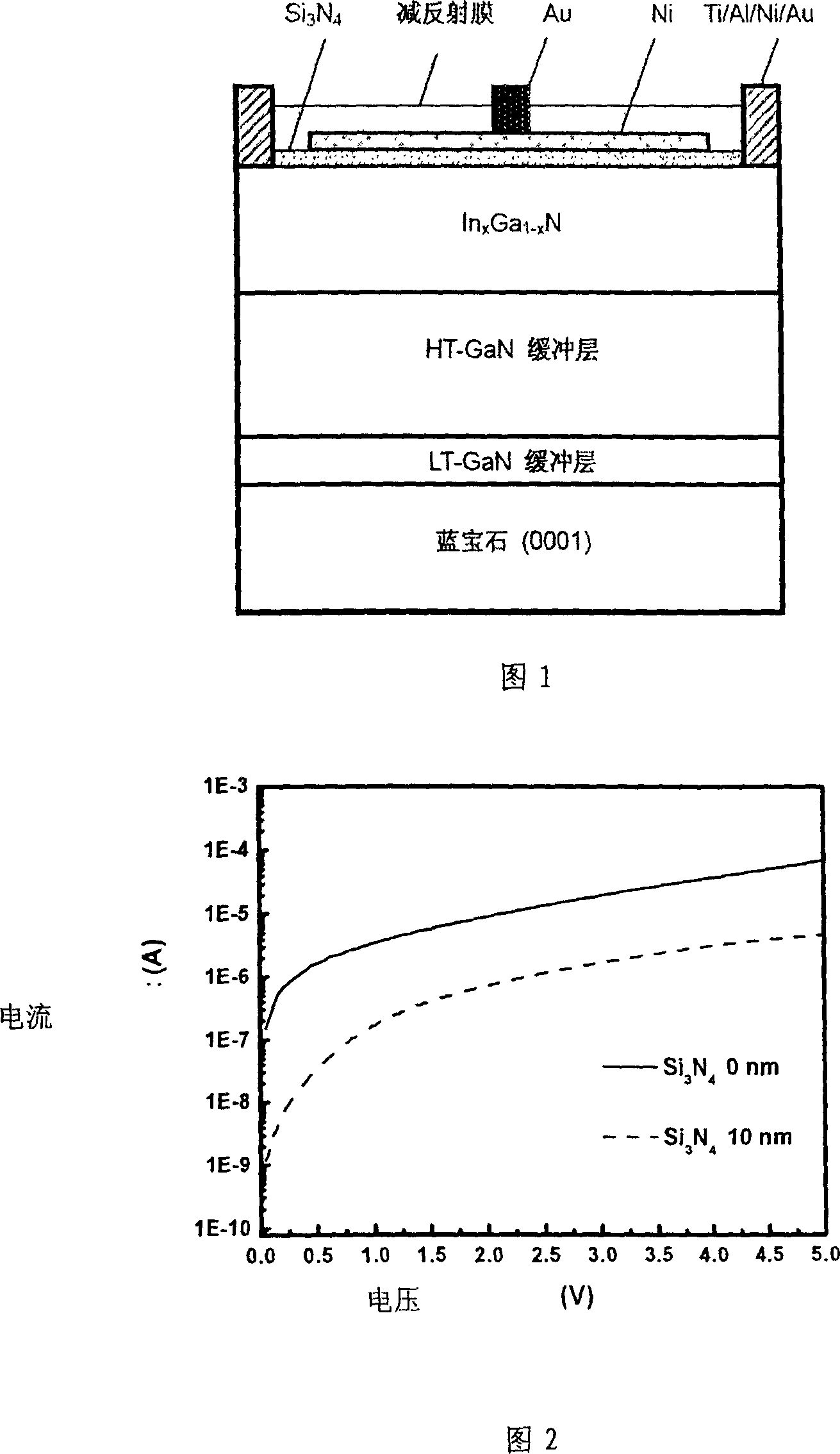

[0020] The structure of the InGaNMIS surface barrier solar cell shown in Figure 1 is grown sequentially on the c-plane (0001) sapphire substrate material: low temperature GaN (LT-GaN) buffer layer, high temperature GaN (HT- GaN) buffer layer, In x Ga 1-x N light absorbing layer, Si 3 N 4 insulating layer, and the Si 3 N 4 The insulating layer is provided with Schottky contact metal, in n-In x Ga 1-x Conductive electrodes are arranged on the N layer. The structure of the InGaN MS surface barrier solar cell is the same as above, except that Si is not grown 3 N 4 insulating layer, directly on the In x Ga 1-x A Schottky contact metal is provided on the surface of the N layer.

[0021] The material growth method is: using MOCVD method to use (0001) sapphire as the substrate to first grow a low-temperature GaN buffer layer, the growth temperature is in the range of 500-700°C, and the thickness is in the range of 20-200nm, and then the low-temperature GaN buffer layer is 9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com