PbTe powde material formation preparing method

A powder material and compression molding technology, which is applied in the field of thermoelectric material manufacturing, can solve the problems of material thermoelectric and mechanical properties reduction, material multi-void, affecting the efficiency and life of thermoelectric generators, etc., to improve mechanical properties and improve thermoelectric properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

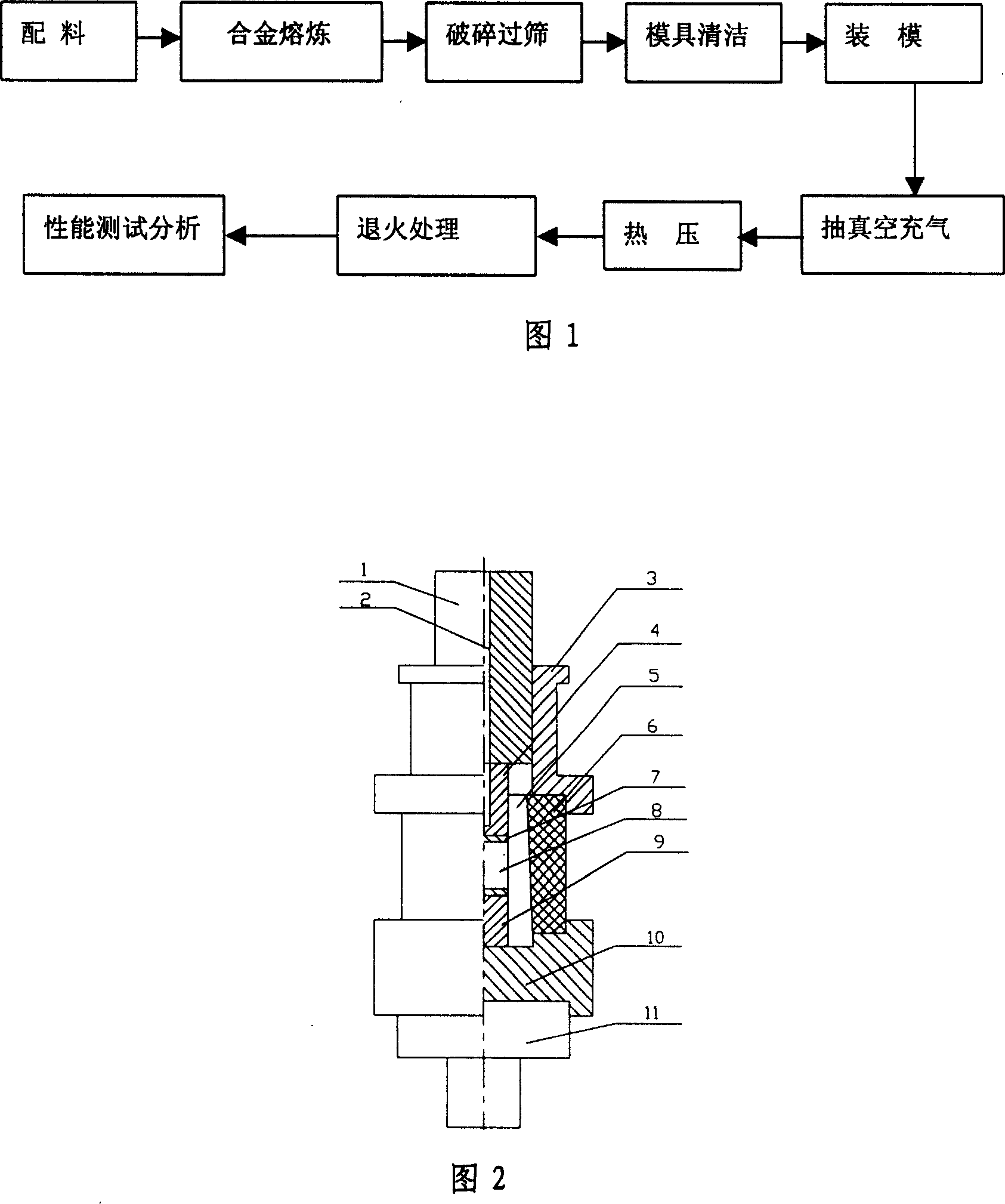

[0011] In order to further understand the invention content, characteristics and effects of the present invention, the following embodiments are enumerated hereby, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0012] Graphite crucibles are pre-cleaned and treated at high temperature. Before each use, brush the inner surface of the crucible with a stainless steel brush, then wipe it with alcohol cotton, and let it dry. 99.999% raw materials are high-purity lead, tellurium, tin and superior pure lead iodide PbI 2 , according to PbTe+0.3(wt)Pb+0.08(wt)PbI 2 The formula, taking the PbTe material size as Φ40×15.5mm as an example, calculates the required PbTe powder 160g, and according to the proportion, calculates the content of each component as Pb: 99.50g, Te60.98g, pbI 2 0.128g, weigh out the amount of each component, put it into a clean graphite crucible, put it into an intermediate frequency furnace, heat it to 950°C for melting, ke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com