Copper evaporating heat-exchanging pipe of evaporator for bromine refrigerator set

A heat exchange tube and fin technology, which is applied in the field of copper evaporation heat exchange tubes, can solve the problems of unreasonable heat exchange performance and energy exchange, lowering the temperature of the working medium in the heat exchange tube, and cannot fully meet the requirements of improving efficiency, etc. The effect of size, faster condensation, and longer service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

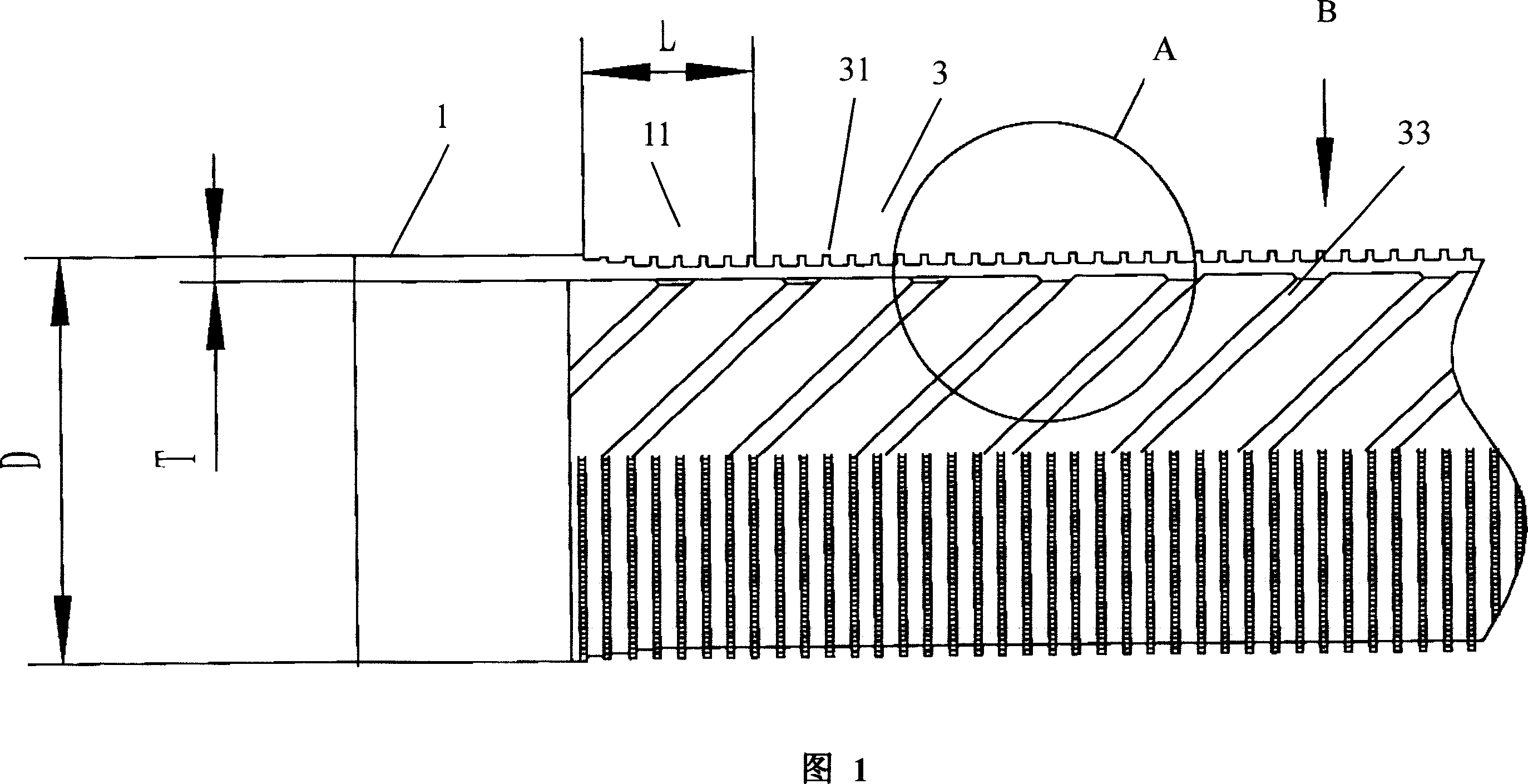

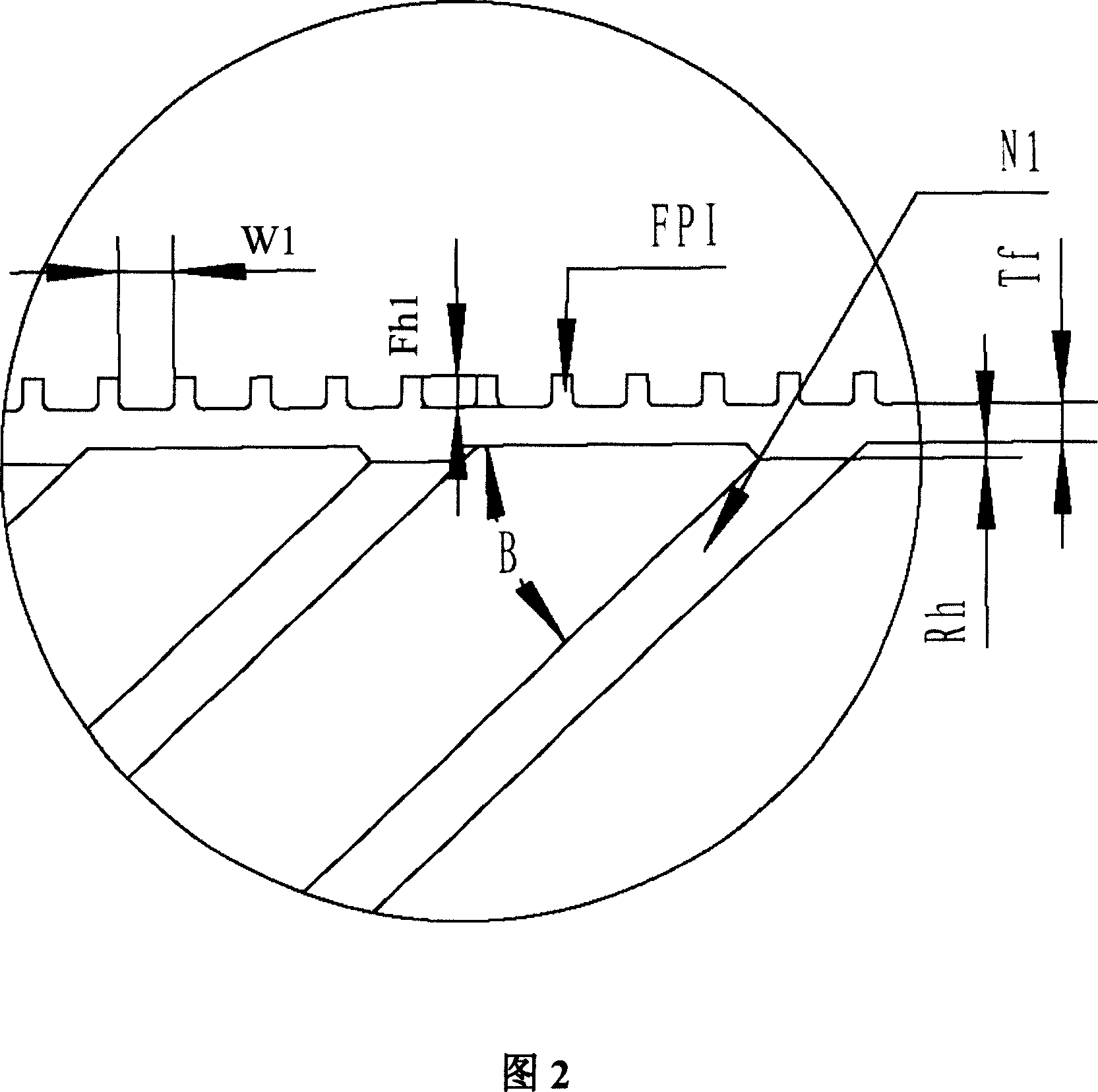

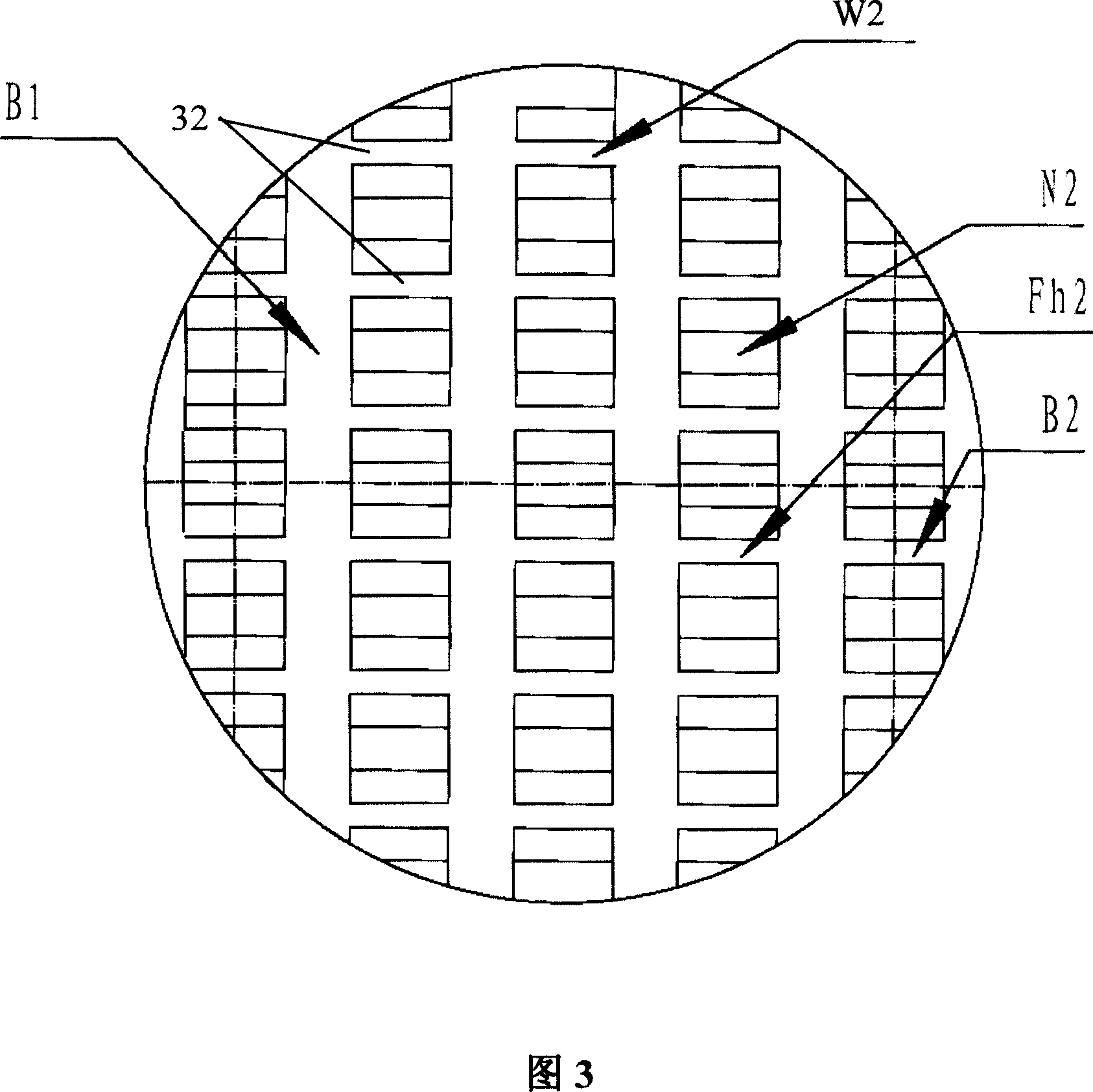

[0020] Please refer to FIG. 1, the heat exchange tube 100 of the present invention includes a polished rod portion 1 located at both ends of the heat exchange tube 100, a finned portion 3 with fins 31 between the two polished rod portions 1, a polished rod portion 1 and a finned portion. The transition part 11 between 3, the inner tooth 33 arranged on the inner surface of the tube, the fin 31 is a single helical fin, and the fin 31 is also provided with a secondary groove 32, and the secondary groove 32 connects the fin 31 partitions form individual fins. Preferably, the heat exchange tube 100 of the present invention is made of copper material.

[0021] The outer diameter D of the polished rod portion 1 of the present invention ranges from 12-26 mm, the wall thickness T ranges from 0.5-0.9 mm, and the length L of the transition portion ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Top angle | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com