Process of preparing diesel oil substitute with domestic garbage and coal

A domestic garbage and coal technology, applied in the energy field, can solve the problems of expensive construction and operation costs, large land occupation, and difficulty in decomposition, and achieve the effects of low product cost, fast commissioning, and short cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

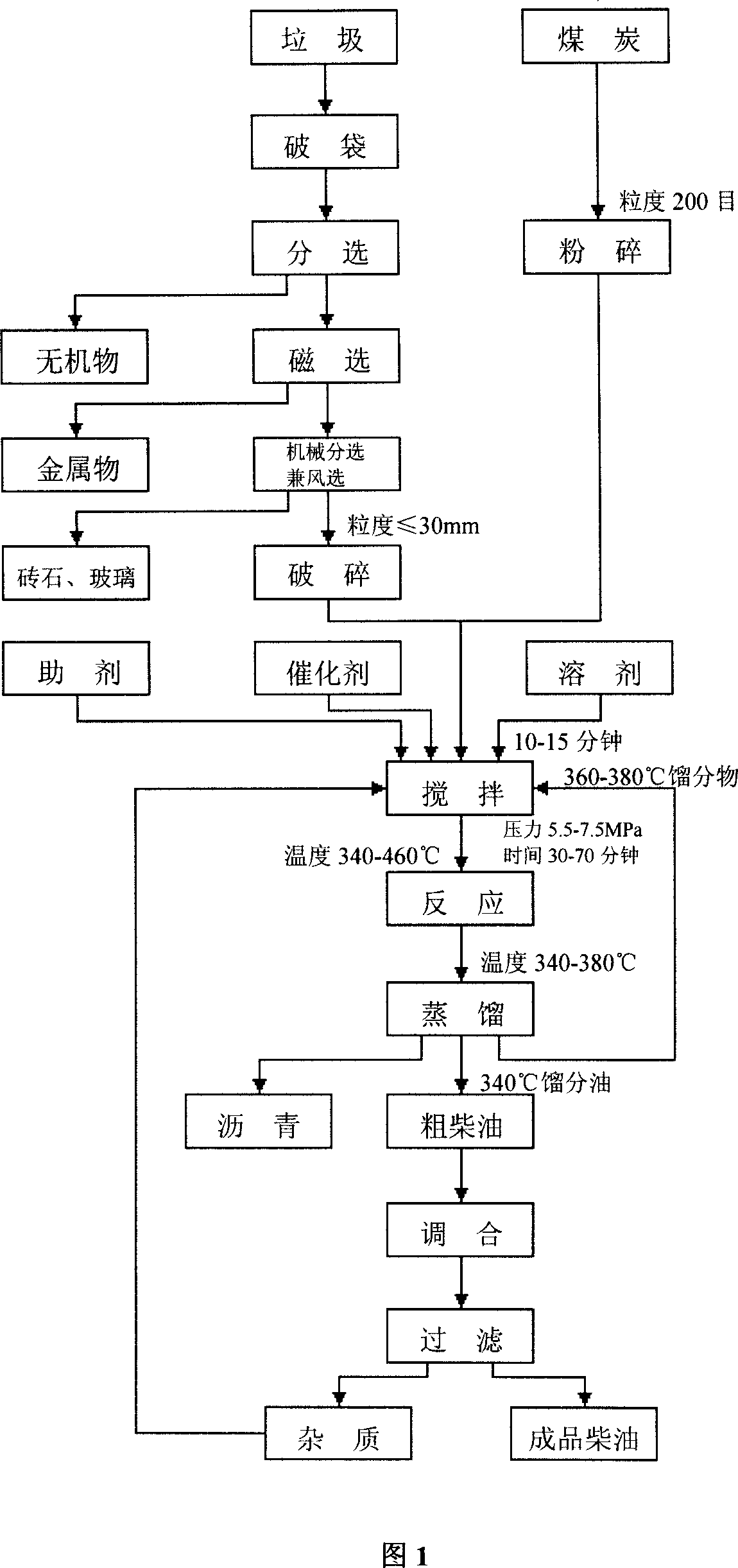

Method used

Image

Examples

Embodiment 1

[0023] First, according to the material formula provided by the present invention and its weight (%) content, determine the material proportion: garbage 45.0, lignite 15.0, solvent 30.0, auxiliary agent 5, catalyst 5; weigh various raw materials by percentage:

[0024] 450kg of rubbish, 150kg of lignite from Shenyang Tiefa Mining, 300kg of anthracene oil as a solvent, 50kg of methanol as an auxiliary agent, and 50kg of catalyst hydrochloric acid.

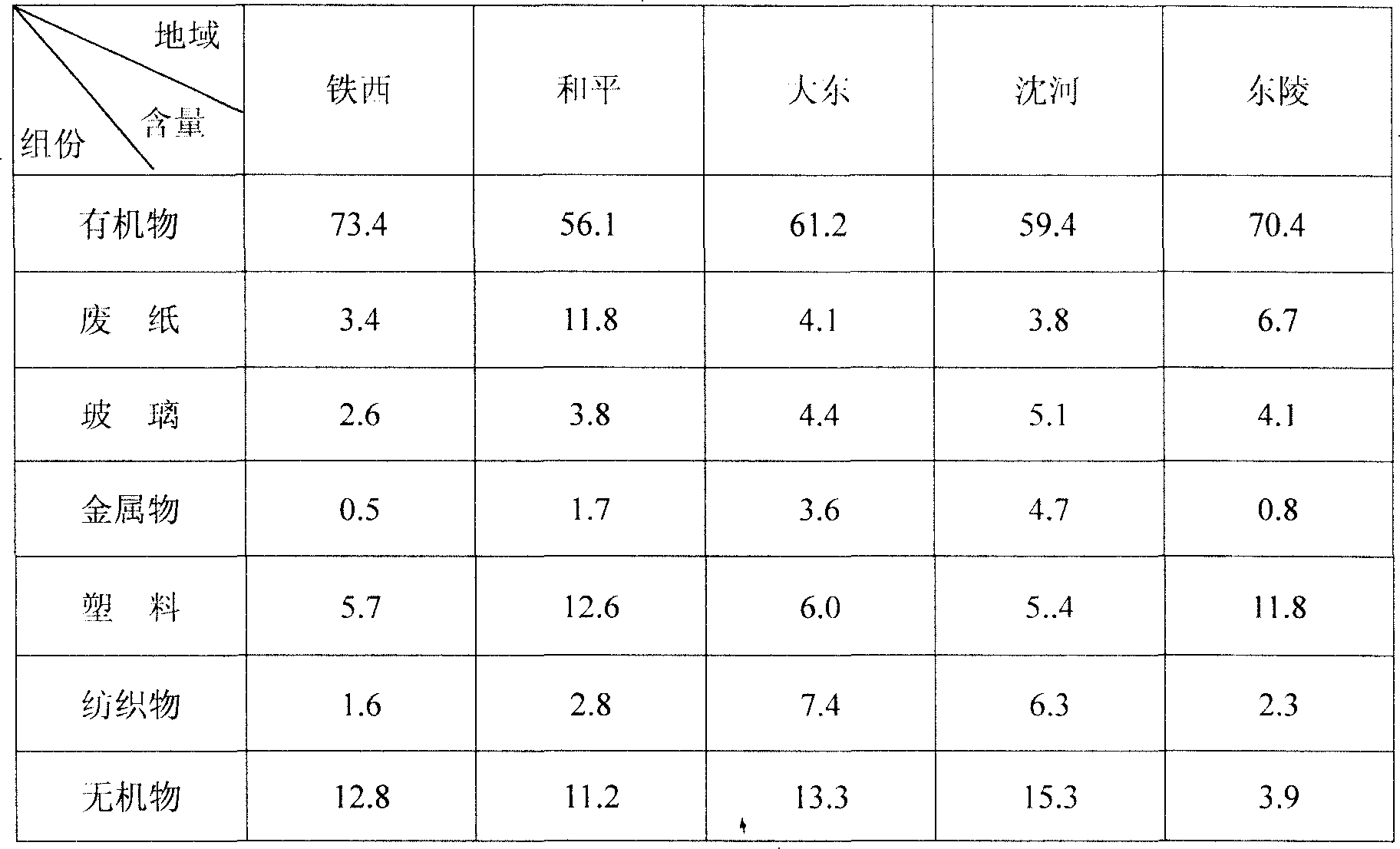

[0025] In this method, the garbage and coal used should be pretreated first. Garbage bags are first broken, and then manually sorted to sort out the inorganic substances of waste batteries; then magnetic separation is performed to remove metal substances; then, masonry and glass substances are removed by mechanical sorting and winnowing; and then through strong crushing , so that the particle size is ≤30mm for later use; the pretreatment of lignite is through pulverization, so that the particle size reaches 200 mesh for later use; t...

Embodiment 2

[0029] According to the method provided by the invention, biodiesel is prepared. 20.0% of Shenyang Puhe sub-bituminous coal, 40.0% of household waste in Tiexi District, 30.0% of distillate oil at 340-380°C as solvent, 5.0% of cetyl alcohol as auxiliary agent, and 5.0% of catalyst industrial hydrochloric acid. Weigh each material, sub-bituminous coal 200kg, garbage 400kg, solvent 300kg, cetyl alcohol 50kg, industrial hydrochloric acid 50kg; after garbage and bituminous coal are pretreated, enter the mixer together with additives, solvents and catalysts, and after fully stirring for 11 minutes, Change over to reaction procedure, reaction temperature is 370 ℃, pressure 7.0MPa, time 60 minutes; Enter blending procedure by the ratio of 0.5%, add amyl nitrate 5kg; The technological parameter of other each procedure is all identical with embodiment 1.

Embodiment 3

[0031] Use domestic waste from residents in Quanyuan District, Dongling District, Shenyang, take Fushun oil shale, weigh materials according to the following composition formula and weight (%) ratio: garbage 35.0%, 350kg, oil shale 25.0%, 250kg, solvent 30.0%, use 340-380 ℃ distillate oil recycling, the dosage is 300kg, methanol 50kg, industrial hydrochloric acid 50kg, various materials enter the mixer, after uniform stirring for 12 minutes, transfer to the reaction process, reaction temperature 400 ℃, pressure 6.5MPa, time 50 minutes; gas oil Enter the blending process, according to the test results, add 0.8% amyl nitrate, and the weight is 8kg;

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com