High speed magnetic resistance motor

A reluctance motor, high-speed technology, applied in the direction of electromechanical devices, electrical components, mechanical equipment, etc., can solve the problems of unsatisfactory synchronization performance, low efficiency and power factor, and small stable operation range of the motor, so as to increase the effective thermal conductivity of the space , good synchronization performance, simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

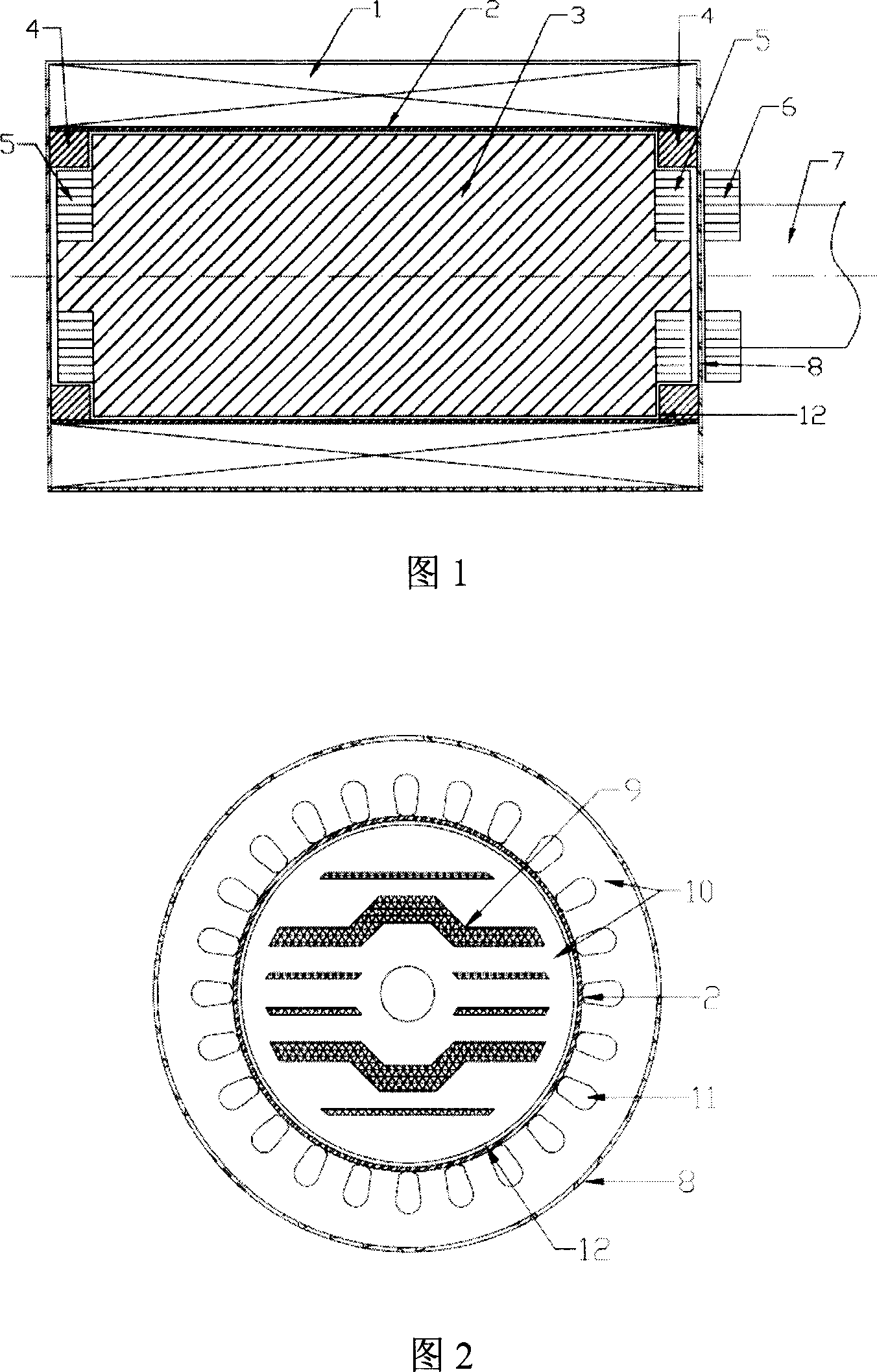

[0032] As shown in Figure 1, the motor body of the present invention consists of a superconducting or constant conducting stator 1, a nonmagnetic thin-walled metal sleeve 2, a rotor 3 embedded with superconducting blocks and strips, and an annular array of superconducting blocks 4 , permanent magnetic ring 5 and non-magnetic metal Dewar 8; high-temperature superconducting block annular array 4, permanent magnetic ring 5 and motor rotor 3 constitute a magnetic bearing; at the same time, the load side magnetic coupling 6, mechanical transmission shaft 7 Constitute the magnetic force transmission mechanism with the permanent magnet ring 5 again.

[0033] Sector-shaped permanent magnets are respectively fixed on the axial end surfaces on both sides of the rotor 3 , and are arranged regularly according to polarity to form a permanent magnet ring 5 . Two sets of ring-shaped high-temperature superconducting block arrays 4 are placed on the inner wall of the sleeve 2, and the position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com