Welding method of high carbon steel for endless hot rolling

A technology of laser welding and process, applied in the direction of laser welding equipment, welding medium, welding equipment, etc., can solve the problem of not being able to ensure stable quality welds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

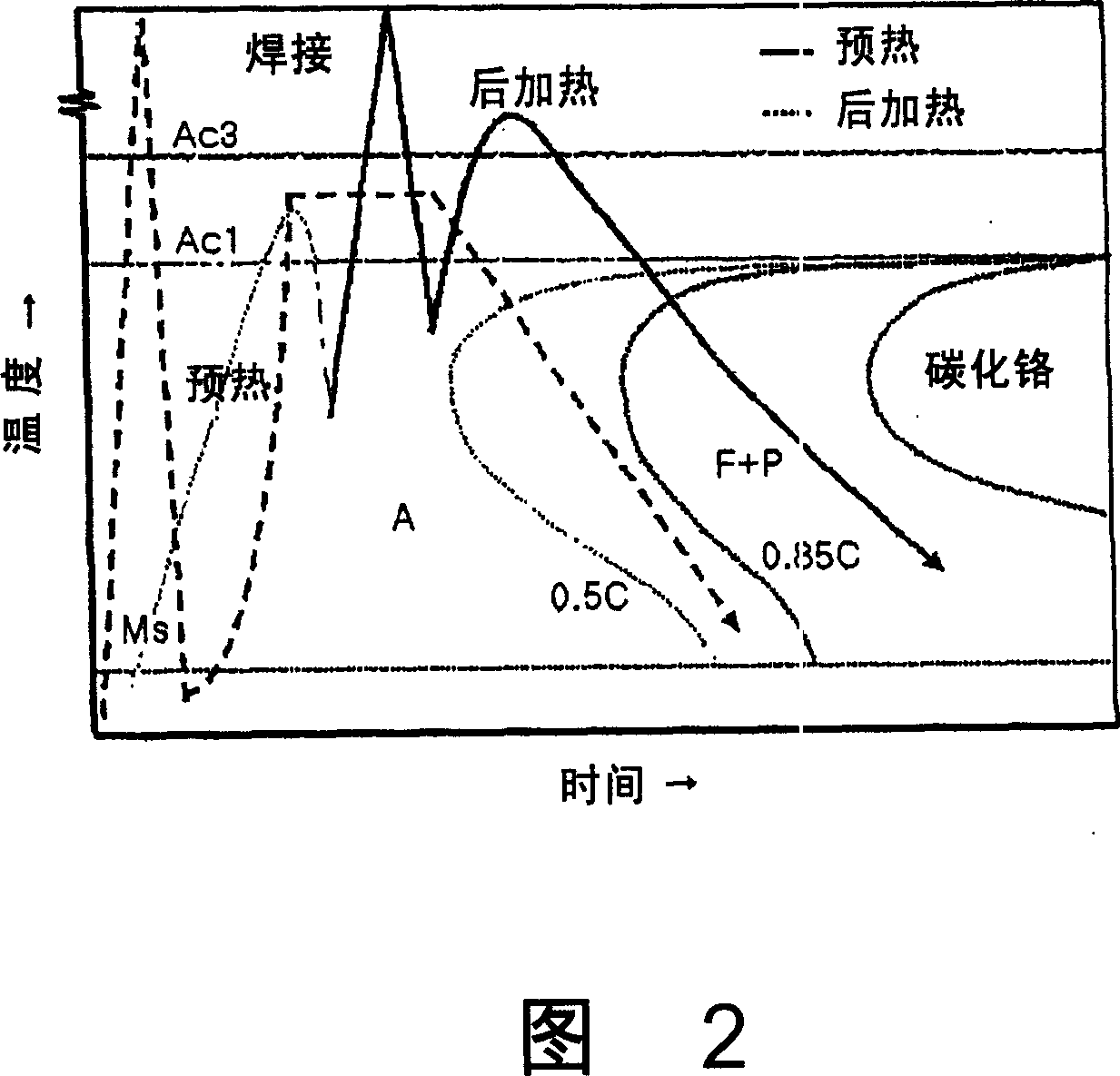

[0040]In this specification, "hot-rolled steel sheets prone to low-temperature transformation" mean hot-rolled steel sheets whose microstructure of the weld seam is in the Transformation occurs at low temperature. The low temperature transformed microstructure means a microstructure comprising martensite and bainite. The hot-rolled steel sheet prone to low-temperature transformation after laser welding also includes high-carbon steel or high-strength steel.

[0041] By high carbon steel is meant steel comprising at least 0.5% by weight of carbon. For example, the high carbon steel consists of at least 0.5% by weight carbon, 0.1-0.5% by weight silicon, 0.3-0.6% by weight manganese, up to 0.05% by weight phosphorus, up to 0.05% by weight Sulfur, up to 0.5% by weight copper, up to 3% by weight nickel, 0.05-0.5% by weight chromium, at least 0.05% by weight aluminum, the balance being iron and unavoidable impurities. In the present invention, unless otherwise stated, percentages...

Embodiment

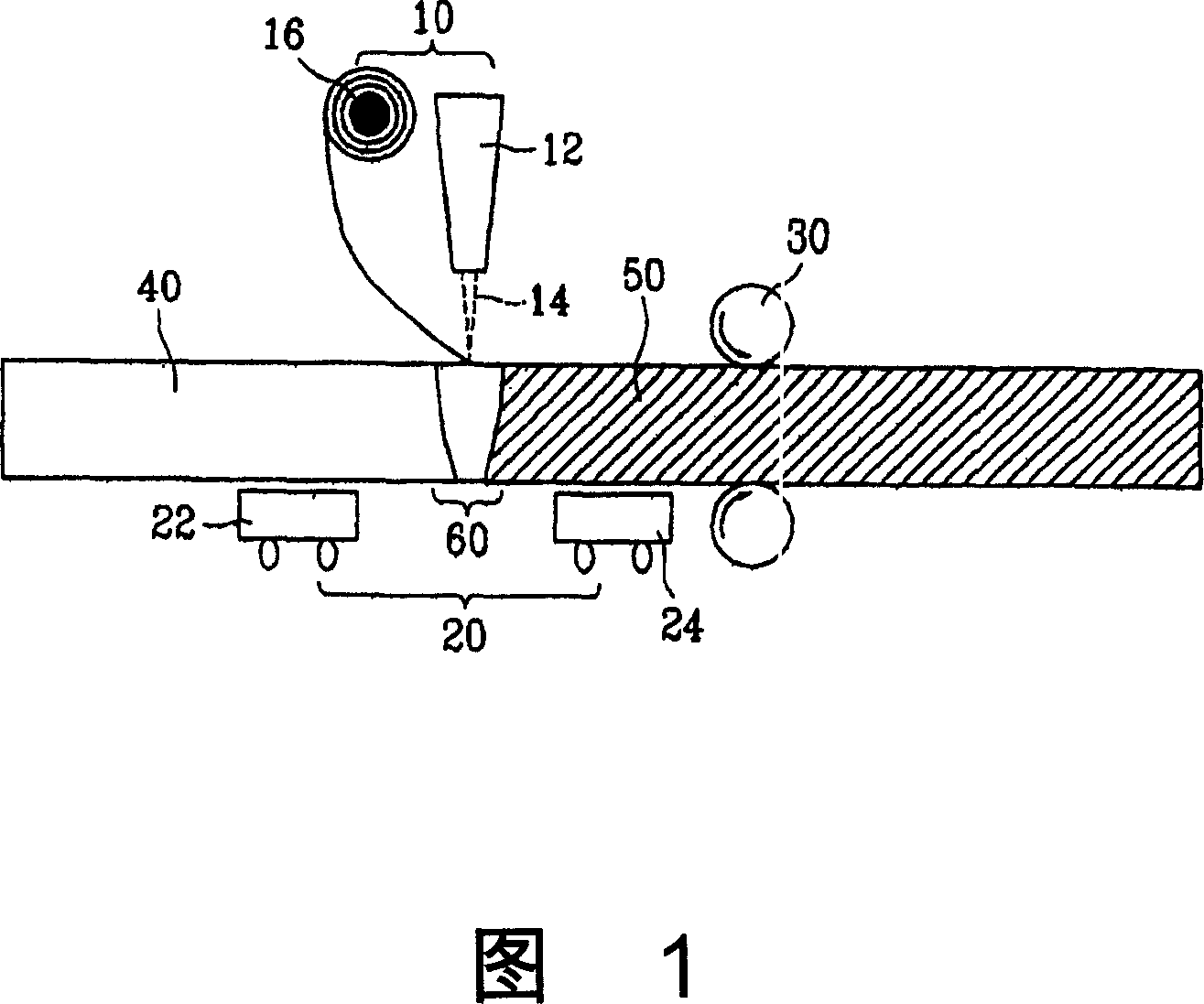

[0083] These examples employed high-carbon steel hot-rolled steel sheets (mainly composed of iron) having the compositions shown in Table 1. These hot-rolled steel plates have a thickness of 2.0 mm and pass through a CO with a maximum output of 12KW 2 Laser welding devices are welded to each other.

[0084] C

Si

mn

P

S

S-Al

Ni

Cr

N

SK85

0.8572

0.193

0.410

0.013

0.003

0.010

0.01

0.16

0.0049

S50C

0.5043

0.192

0.704

0.020

0.003

0.016

0.01

0.09

0.0026

[0085] These examples also use filiform filler (Φ0.9 mm) as the welding material. Welding consumables with compositions shown in Table 2 include ER70S-G and ER80S-G based on carbon steel, ER308 based on stainless steel, and ERNiCrMoO based on nickel alloy 3 and ERNi. The carbon steel-based ER70S-G and ER80S-G have iron as the main chemical compositio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com